After

the rear

table

has been set at the

correct

height, it

should

not

be changed

except

for special

operati

ons

and

afte

r sharpening knives.

If the rear table is

too

high, the result

will

be as

shown in Fig.

6.

The finished surface

will

be curved.

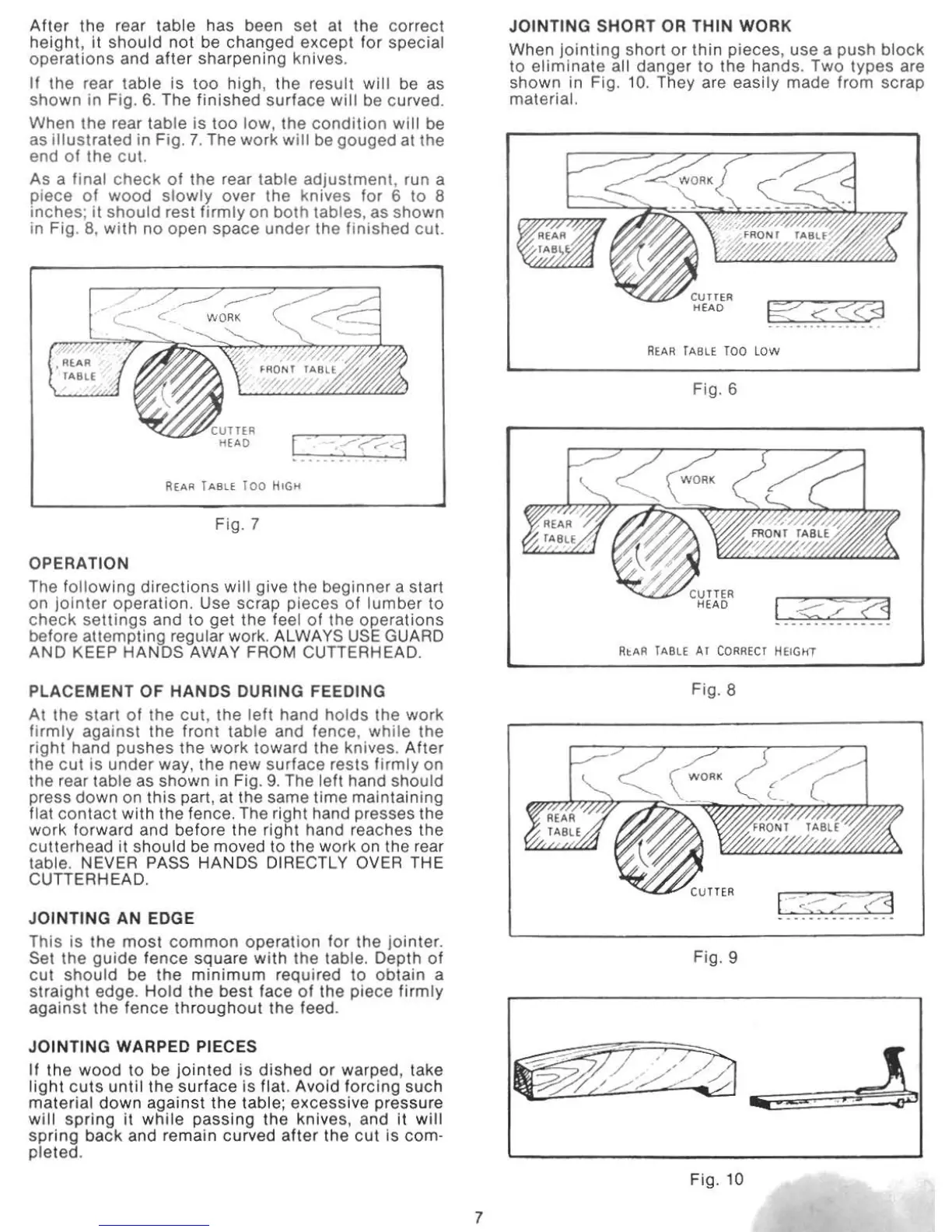

When

the

rear table is

too

low, the

condition

will

be

as

illustrated

in Fig.

7.

The work

will

be

gouged at the

end

of

the

cut.

As a final

check

of

the rear table

adjustment

, run a

piece

of

wood

slowly

over the knives for 6 to 8

inches

;

it

should

rest

firmly

on both tables. as shown

in Fig.

8,

with

no open space under the finished cut.

RfA

R

TA8lf

10

0

HIC;I-l

Fig.7

OPERATION

The

following

directions

will

give the beginner a start

on

jointer

operation. Use scrap pieces

of

l

umber

to

check

settings

and to get the feel

of

the operations

before attempting regular work. ALWAYS

USE

GUARD

AND

KEEP

HANDS

AWAY

FROM CUTTERHEAD.

PLACEMENT

OF

HANDS

DURING FEEDING

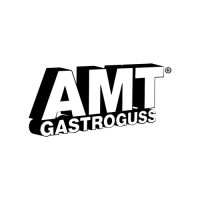

At the start

of

the cut, the

left

hand

holds

the work

/irmly

against the front table and fence,

while

the

right

hand

pushes

the

work

toward the knives.

After

the

cut

is under way, the new surface rests f

irmly

on

the rear table as shown in Fig.

9. The left hand should

press

down

on

this

part, at the same time maintaining

flat contact with the fence. The right hand presses the

work

forward and before the right hand reaches the

cutterhead it should be moved to the work on the rear

lab

Ie. NEVER PASS

HANDS

DIRECTLY OVER THE

CUTTERHEAD.

JOINTING

AN EDGE

This is the

most

common

ope

ra

tion for the jointer.

Set the guide fence square

with

the table. Depth

of

cut

should

be the

minimum

requ ired to

obtain

a

straight edge. Hold the best face

of

the

piece

f

irml

y

against the fence

throughout

the feed.

JOINTING

WARPED PIECES

If

the

wood

to be jointed is dished or warped, take

light

cuts

until the surface is flat. Avoid for

cing

such

materia

l

do

wn against the table; excessive pressure

will

spring it

while

passing the knives, and it

will

spring back and remain curved

after

the cut is com-

pleted

.

7

JOINTING

SHORT OR THIN WORK

When

jointing

short

or

thin pieces, use a push

block

to

eliminate

all danger

to

the

hands. Two types are

shown in Fig.

10.

They are easily made from scrap

material.

REAR

TABLE

TOO

lOw

Fig.6

RtAR

TABLE

AI

CORRECT

HEIGHT

Fig

.8

Fig.9

....

_,

....•

Fig.

10

Loading...

Loading...