14

MTX-R 2nd Stage Maintenance Manual

FINAL TESTING

Setting the Lever Height

2. Screw the Inline

Adjustment Tool onto

the threaded end of the

2nd stage. Attach the

rst stage to a cylinder

containing 207 Bar

(3000 psi). Slowly open

the cylinder valve and

pressurise the reguator.

3. Purge the 2nd stage 2

to 3 times to check there

is air ow.

1. Attach an Inline

Adjustment Tool (AT72)

to a regulator hose

on a correctly set rst

stage. Refer to the

appropriate rst stage

technical manual before

attempting to perform

any adjustments.

4. Strike the purge

button again 3 times to

check there is no free

ow. If the 2nd stage

does freeow check

the following 3 notes to

determine the reason.

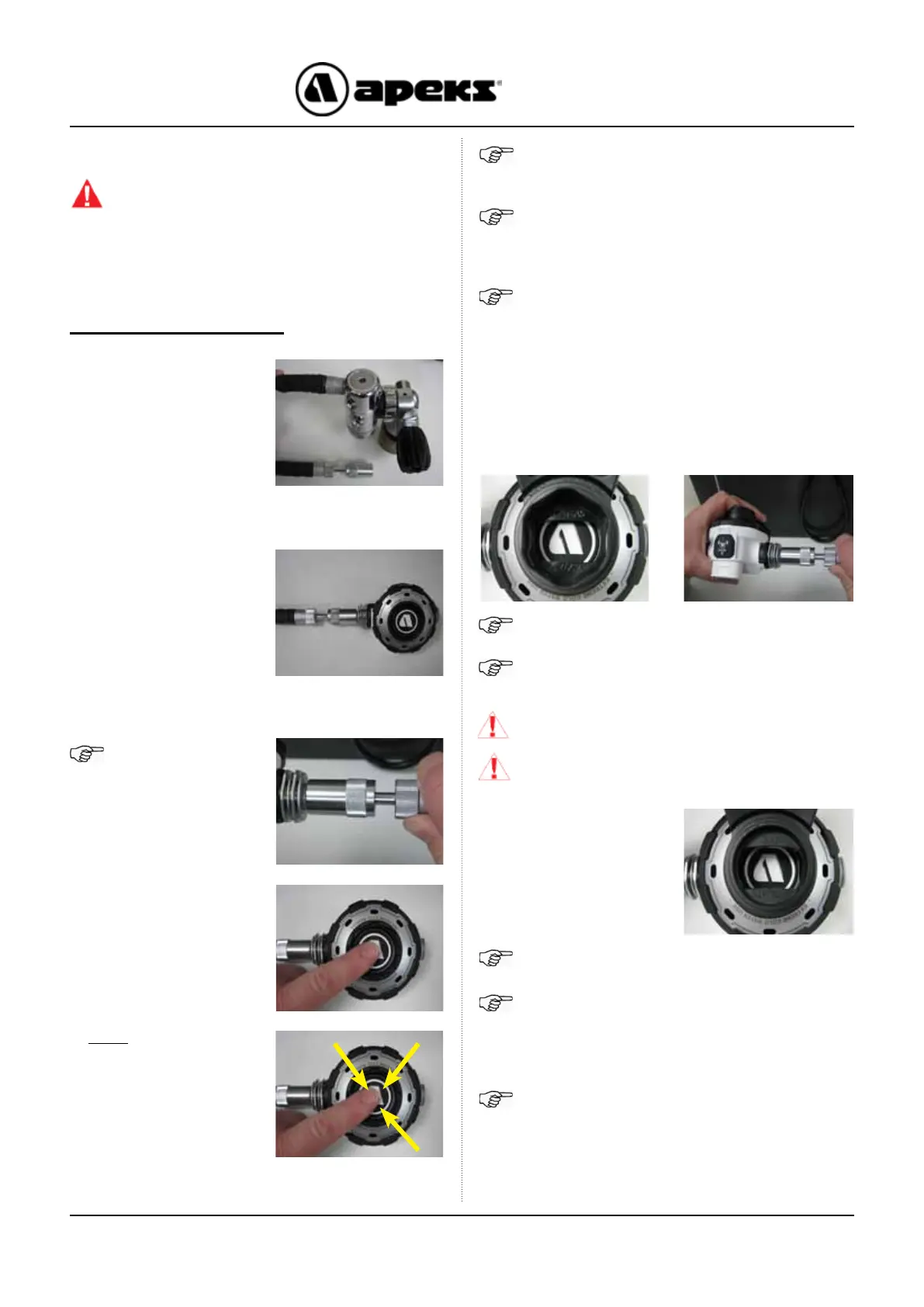

5. Place the “GAS FLOW” side of the testing puck

section on the Front Cover Tool (AT94) over the purge

button.There should be a ow of air, if not adjust the

inline adjuster counter clockwise in 1/16 turns until

there is a steady ow.

NOTE: It is important to ensure that the rim of

the tool is concentric with the rim of the purge

button throughout. Pressing on the logo with the

tool misaligned will not measure the purge button

depth and therefore give incorrect results.

NOTE: If there is gas ow, keep the puck on

“NO GAS FLOW” and turn the inline adjuster

clockwise in 1/16 increments until the ow

ceases. Turn the puck back to “GAS FLOW” to

make sure there is still air ow.

Warning: Compressed air can be highly

explosive and is dangerous if misused.

Ensure cylinder valve is opened slowly. Use

eye and ear personal protective equipment

when performing any tests involving

compressed air.

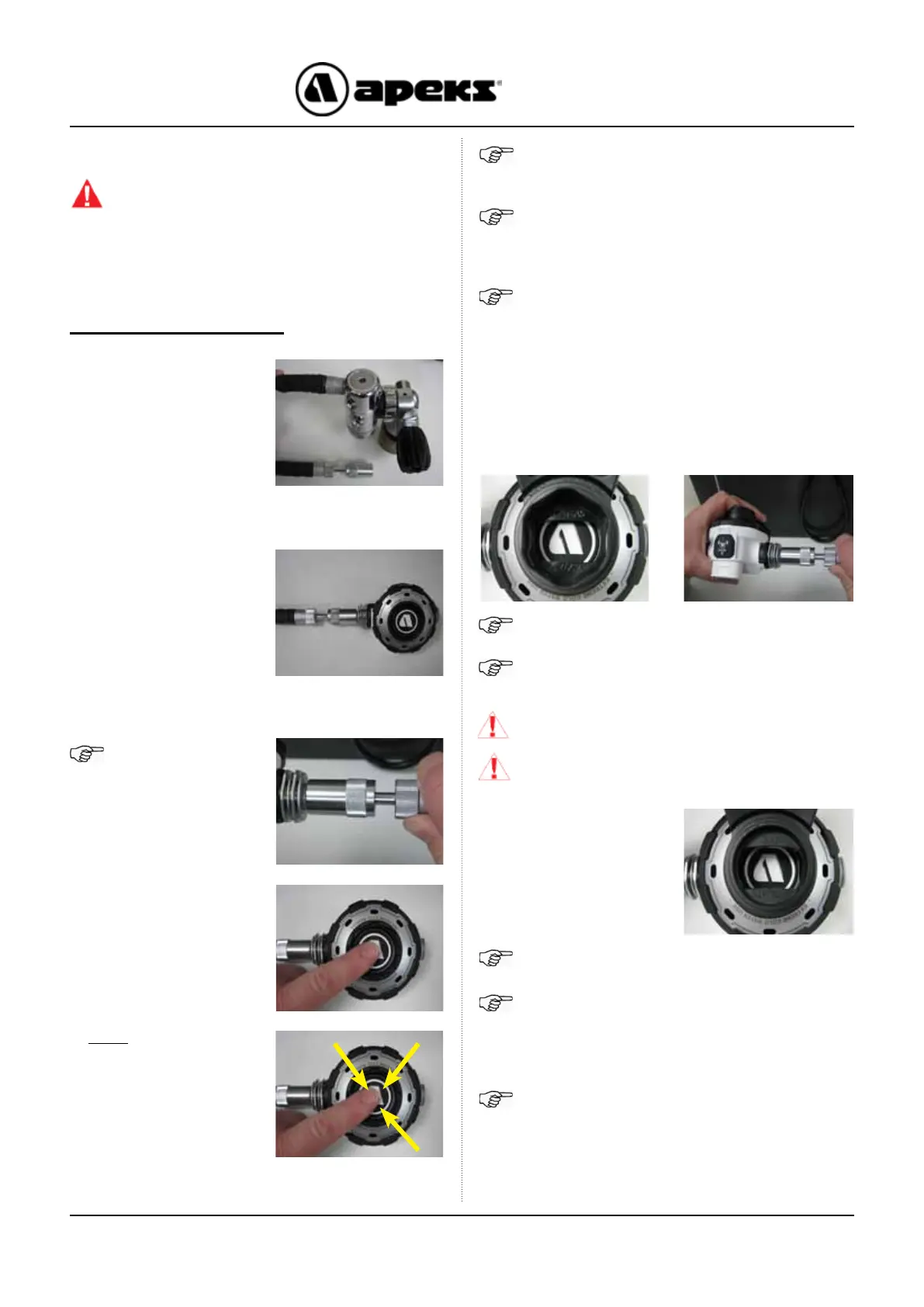

6. Turn the puck section

of the adjustment tool to

the opposite side “NO

GAS FLOW” to check

that the lever is set

correct and there is no

ow of air.

NOTE: If the 2nd

stage is leaking

turn the inline

adjuster clockwise

until the leaking

stops.

NOTE: Check that the two ats and the two

Lever feet engage in the tabs of the Blanking

Piece. Refer to step 18 on page 12.

NOTE: Check that the Venturi lever body is lined

up with the venturi blank. Refer to step 15 on

page 11.

NOTE: Check the lever is vertical. Refer to steps

20 & 21 on page 12

CAUTION: The air ow should be continuous

with no uttering

NOTE: Keep the puck in place whilst making

adjustments

CAUTION: Free ow test should be done

every time the lever height has been adjusted.

NO GAS

MTX/ATX

NOTE: “NO GAS” will be visible when performing

gas ow setting.

GAS

MTX/ATX

NOTE: “GAS” will be visible on the tool when

checking no gas ow.

Loading...

Loading...