18

MTX-R 2nd Stage Maintenance Manual

CAUTION: Ensure Diaphragm is seated

correctly and not creased.

Before tting hose, carry out vacuum test by

holding thumb over Valve Spindle (17) to seal and

trying to breathe through mouthpiece outlet port.

No air should be inhaled.

This Ends the Conversion Procedure,

Proceed to Final Testing

NOTE: If your facility is equipped with a test bench,

remove the mouthpiece as described on page 6.

General instructions for performing bench tests are

located in the section, “Final Testing” on page 14.

CAUTION: Excessive tightening of the Heat

Exchanger will damage the Blanking Piece

and Case.

16.Using an 28mm

crows foot, tighten the

Heat Exchanger (9) to

a torque of 3 Nm (2.2

ft/lb).

CAUTION: Ensure that the Lever is vertical

after tightening.

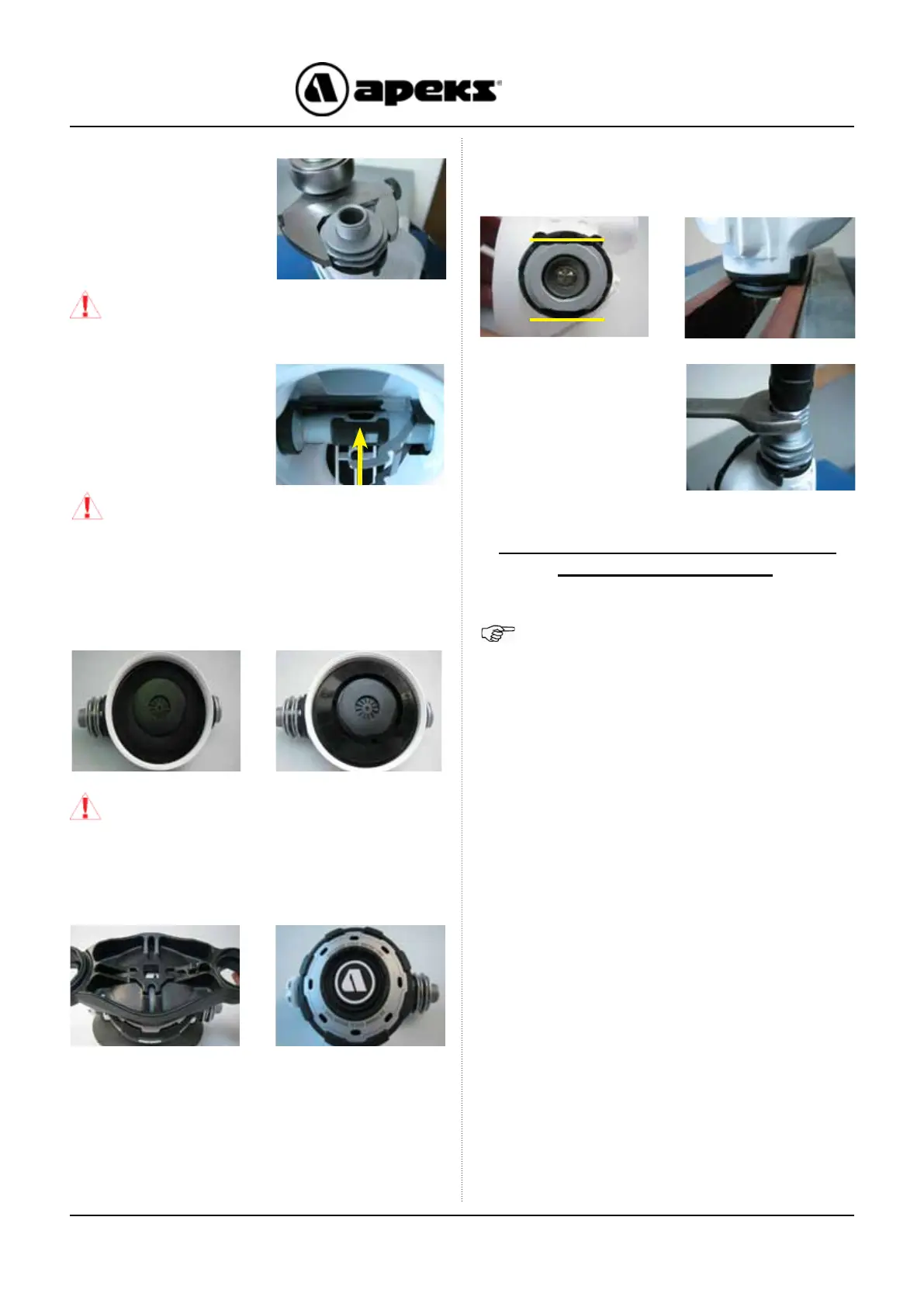

20. Fix the second stage into a soft jawed vice as

explained in section 15.

21. Screw the Hose

onto the second

stage. Using an 11/16”

crowsfoot and torque to

5Nm (

3.7 ft/lb).

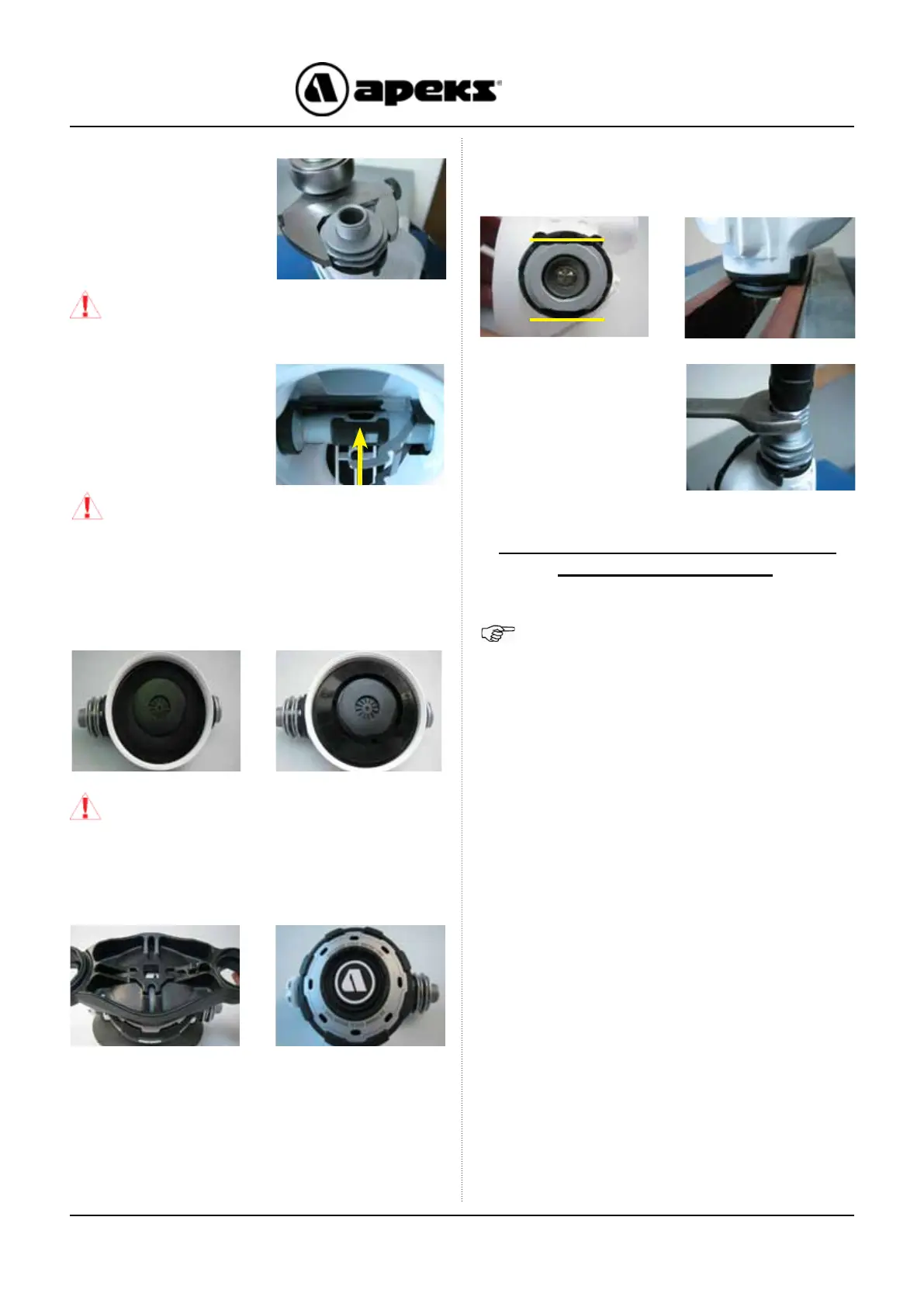

18. Position the Diaphragm (4) into the Case (6). Using

your nger, work the edges of the Diaphragm into place so

it sits evenly in the Case . Install the Diaphragm Cover (3)

into the Case, over the Diaphragm.

17. Ensure the Valve

Spindle hole points to the

top of the case.

19. Screw the Case Cover (2) onto the Case (6). Using

Tool AT94 tighten the Cover until it stops. Conrm that the

Purge Button is properly aligned.

Loading...

Loading...