20

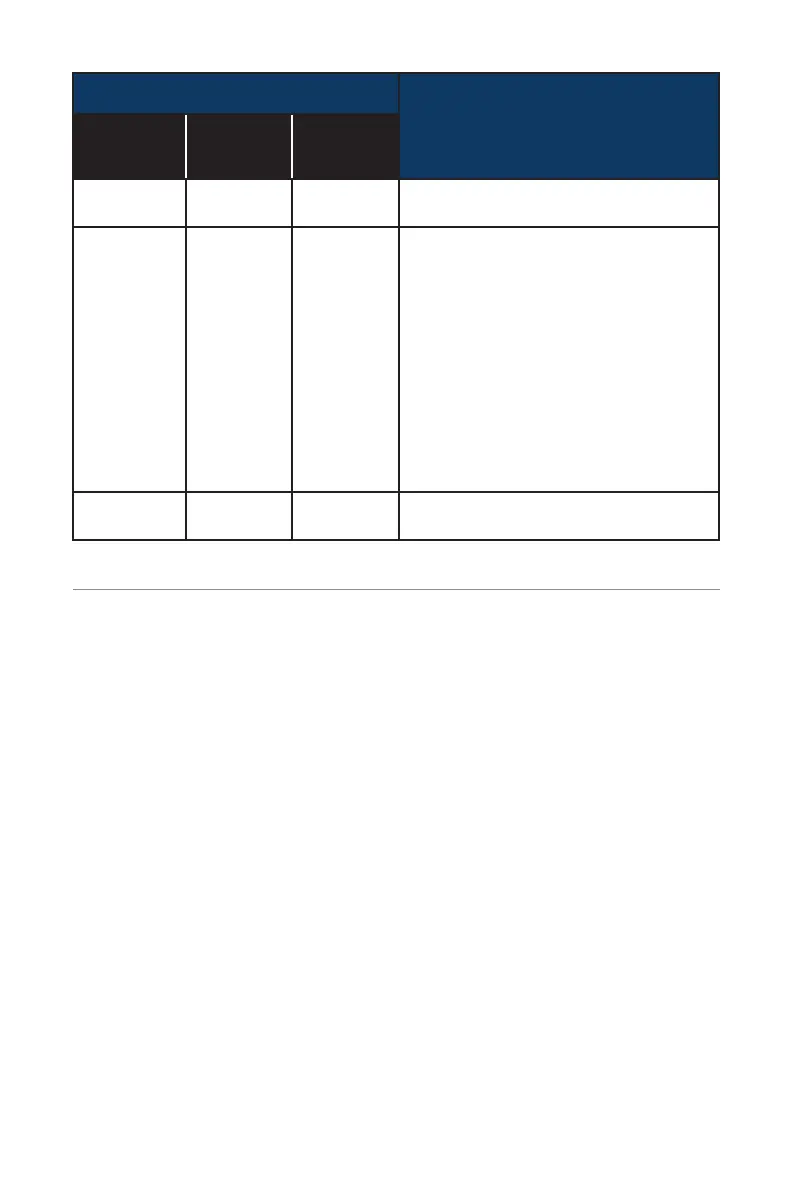

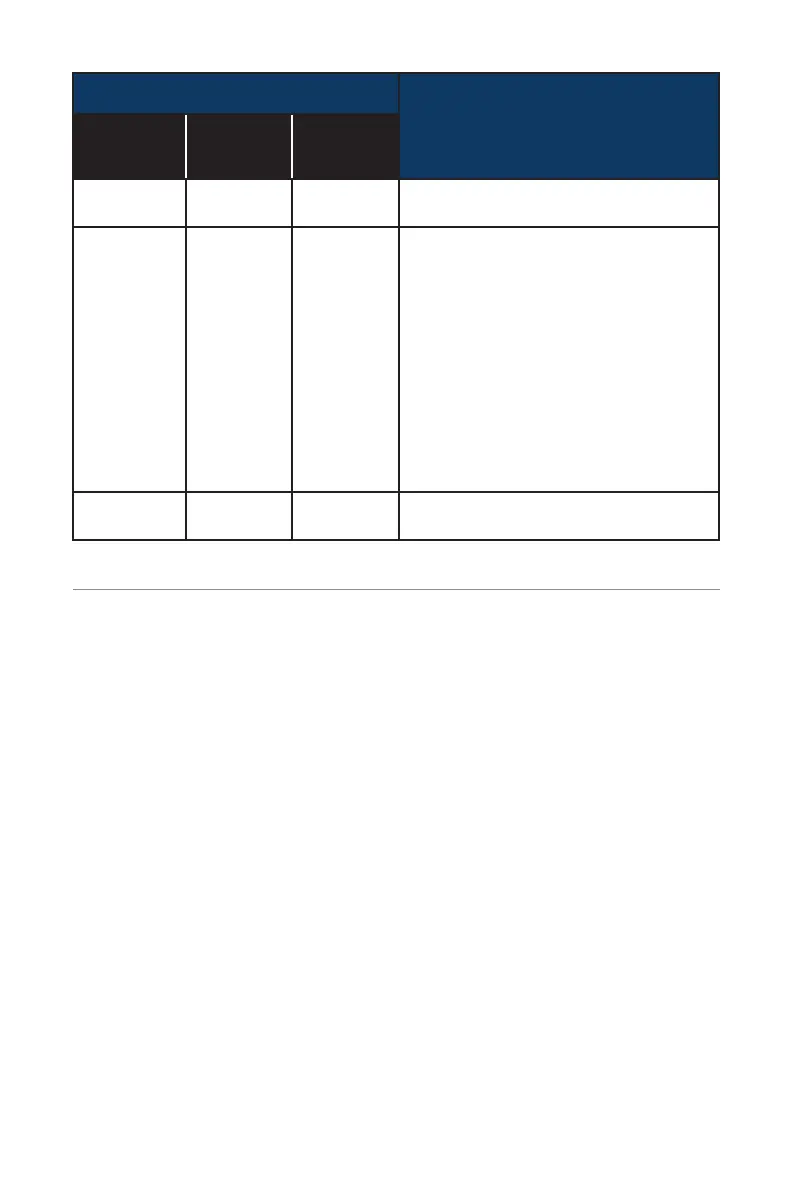

SYSTEM STATUS

REMARKS

LAMP

STATUS

(GREEN LED)

AUDIBLE

ALARM

UV LAMP

ON OFF ON

Correct operating conditions, unit is

functioning properly

OFF ON OFF

The UV lamp is spent, requires replacement

lamp.

UV lamp not connected to power source.

Check connection and reconnect lamp.

Ballast has switched off. To reset ballast

remove power to unit by disconnecting

power cord from electrical plug for a

minimum of 30 seconds then reapply power.

LED indicator burnt out or wire lead broken.

Replace LED assembly.

OFF OFF ON

LED indicator burnt out or wire lead broken.

Replace LED assembly.

WATER CHEMISTRY

Water quality is extremely important for the optimum performance of your UV

system. The following levels are recommended for installation:

• Iron:<0.3 ppm (0.3 mg/L)

• Hardness *:< 7 ppm (120 mg/L)

• Turbidity: < 1 NTU

• Manganese: < 0.05 ppm (0.05 mg/L)

• Tannins: < 0.1 ppm (0.1 mg/L)

• UV Transmittance: > 75%

(Call factory for recommendations on applications where UVT < 75%)

* Where total hardness is more than 7 gpg, the UV unit should operate efciently provided the

quartz sleeve is cleaned periodically. If total hardness is over 7 gpg, the water should be softened.

If your water chemistry contains levels in excess of those mentioned above, proper

pre-treatment is recommended to correct these water problems prior to the installation

of your UV disinfection system. These water quality parameters can be tested by your

local dealer, or by most private analytical laboratories. Proper pre-treatment is essential

for the UV disinfection system to operate as intended.

Loading...

Loading...