4

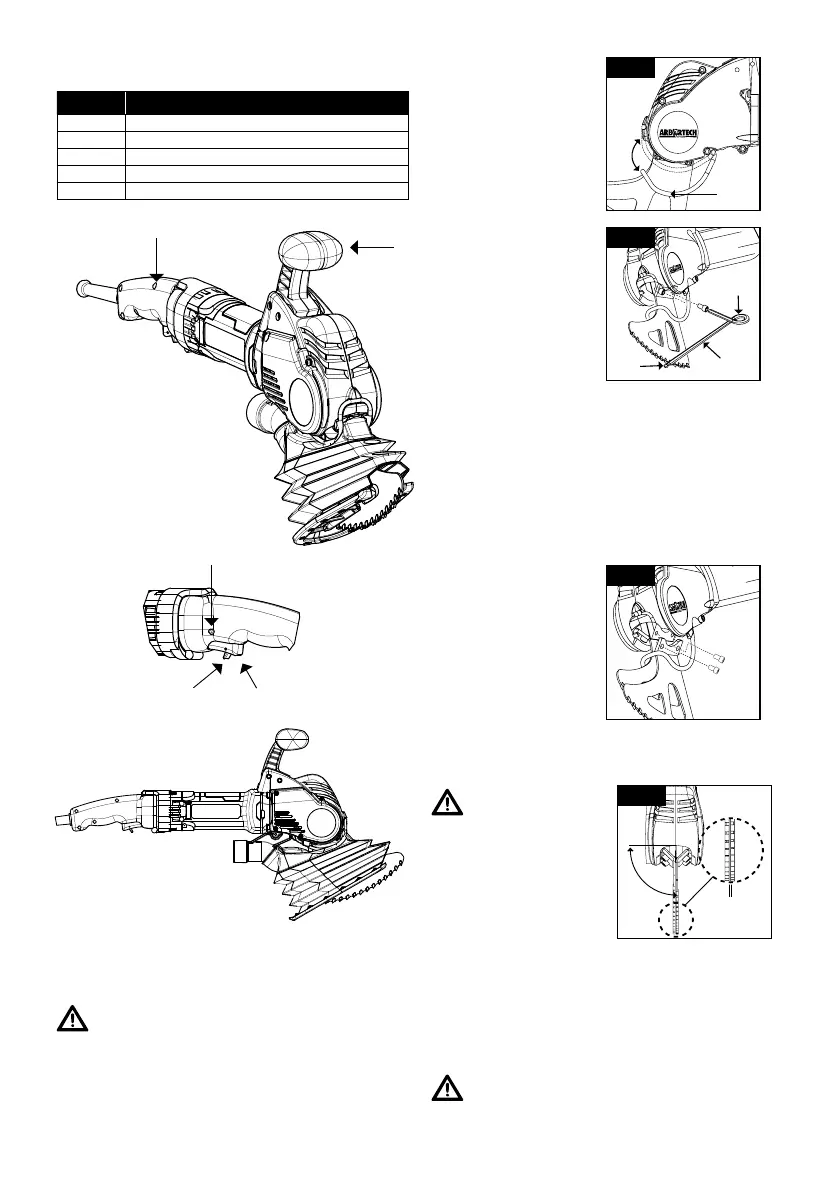

4. ASSEMBLY

ITEM DESCRIPTION

1 Rear handle

2 Trigger switch

3 Lock-off lever

4 Lock on button

5 Top Handle

5

TITLE:

ASSEMBLY NO.

DRAWING NO.

EST. MASS:

DRAWN BY:

DATE:

CHECKED:

APPROVED:

SHEET:

ASSEMBLY NOTES:

CONFIDENTIAL

COPYRIGHT AND DESIGN

RIGHTS REMAIN THE SOLE

PROPERTY OF ARBORTECH

INDUSTRIES PTY LTD.

PROPRIETRY INFORMATION

DISCLOSURE OR

REPRODUCTION PROHIBITED

WITHOUT WRITTEN

APPROVAL FROM ARBORTECH

INDUSTRIES PTY LTD.

67 WESTCHESTER RD MALAGA

WESTERN AUSTRALIA 6062

PH. +618 9249 1944

12345678910111213

A

B

C

D

E

F

G

H

I

A

B

C

D

E

F

G

H

I

12345678910111213

A3

1 OF 3110079146.430 kg SCALE: 0.100BT

AS175-A001-00AS175-A001-01

ALL MATERIALS TO BE ROHS

COMPLIANT

09-Oct-18

AS175

AS180-A005-AA

UNSPECIFIED TOLERANCES

TO FOLLOW ISO-2768-F

DIMENSIONS IN MILLIMETRES

ARBORTECH INDUSTRIES PTY LTD

REV

DETAILS

APRVD DATE

A ISSUED FOR REVIEW

QTY.MATERIALPART NAMEPART NO.INDEX

1AISI_1020DRIVEN PULLEYAS175-P003-AC1

1AISI_1020TENSION IDLERAS175-P004-AA2

1AISI_4140DRIVE PULLEYAS175-P002-AB3

1AL6061RIGHT HAND HOUSINGAS175-P012-024

4FE40TPTR_7211_35

1NYLONbody_back_as180_a_c.prtBODY_BACK_AS180_A_C6

1NYLONbody_mid_as180_a_c.prtBODY_MID_AS180_A_C7

1PA6-GF30BELT COVERAS175-P021-018

1PA6-GF30VACUUM ADAPTERAS175-P010-AA9

1STAINLESS_STEEL_MARTENSITICSPRING GUARDAS175-P008-0110

2AS175-P009-0111

4M4X12_SCREW12

4TPTR_6010_113

5TPTR_6012_014

4TPTR_6014_015

2TPTR_6016_016

1TPTR_6019_017

2TPTR_6022_018

1TPTR_6024_019

1TPTR_6025_020

1TPTR_6026_021

2TPTR_6028_022

4TPTR_6029_023

1TPTR_6031_024

1TPTR_7087_225

2TPTR_7093_1

26

1TPTR_7205_027

1TPTR_8096_128

1TPTR_10011_229

2TPTR_AS_6008_030

1as170-a005-01.asmAS175-A005-0131

1as175-a001-ac.asmAS175-A003-AC32

1as175-p006-aa.prtAS175-P006-AA33

1as175_a004_01_top-handle.asmAS175_A004_01_TOP-HANDLE34

1AS180-P002-01AS180-P002-0135

1circlip_i19.prtCIRCLIP_I1936

1dwe4277-air-baffle.prtDWE4277-AIR-BAFFLE37

1O-RING-BS020O-RING-BS02038

1optibelt_epj.prtOPTIBELT_EPJ39

1optibelt_ph.prtOPTIBELT_PH40

1optibelt_pj260.prtOPTIBELT_PJ_EXT_IDLER41

1optibelt_pj280.prtAS175-P022-042

1tptr-9094-0-rh.asmTPTR_9094_0_RH43

1tptr_8119_7.asmTPTR_8119_744

1tptr_9094_0_lh.asmTPTR_9094_0_LH45

SCALE 0.500

1

TITLE:

ASSEMBLY NO.

DRAWING NO.

EST. MASS:

DRAWN BY:

DATE:

CHECKED:

APPROVED:

SHEET:

ASSEMBLY NOTES:

CONFIDENTIAL

COPYRIGHT AND DESIGN

RIGHTS REMAIN THE SOLE

PROPERTY OF ARBORTECH

INDUSTRIES PTY LTD.

PROPRIETRY INFORMATION

DISCLOSURE OR

REPRODUCTION PROHIBITED

WITHOUT WRITTEN

APPROVAL FROM ARBORTECH

INDUSTRIES PTY LTD.

67 WESTCHESTER RD MALAGA

WESTERN AUSTRALIA 6062

PH. +618 9249 1944

12345678910111213

A

B

C

D

E

F

G

H

I

A

B

C

D

E

F

G

H

I

12345678910111213

A3

2 OF 3110079146.430 kg SCALE: 0.250BT

AS175-A001-00AS175-A001-01

ALL MATERIALS TO BE ROHS

COMPLIANT

09-Oct-18

AS175

AS180-A005-AA

UNSPECIFIED TOLERANCES

TO FOLLOW ISO-2768-F

DIMENSIONS IN MILLIMETRES

ARBORTECH INDUSTRIES PTY LTD

REV

DETAILS

APRVD DATE

A ISSUED FOR REVIEW

4

3 2

TITLE:

ASSEMBLY NO.

DRAWING NO.

EST. MASS:

DRAWN BY:

DATE:

CHECKED:

APPROVED:

SHEET:

ASSEMBLY NOTES:

CONFIDENTIAL

COPYRIGHT AND DESIGN

RIGHTS REMAIN THE SOLE

PROPERTY OF ARBORTECH

INDUSTRIES PTY LTD.

PROPRIETRY INFORMATION

DISCLOSURE OR

REPRODUCTION PROHIBITED

WITHOUT WRITTEN

APPROVAL FROM ARBORTECH

INDUSTRIES PTY LTD.

67 WESTCHESTER RD MALAGA

WESTERN AUSTRALIA 6062

PH. +618 9249 1944

12345678910111213

A

B

C

D

E

F

G

H

I

A

B

C

D

E

F

G

H

I

12345678910111213

A3

2 OF 3110079146.430 kg SCALE: 0.250BT

AS175-A001-00AS175-A001-01

ALL MATERIALS TO BE ROHS

COMPLIANT

09-Oct-18

AS175

AS180-A005-AA

UNSPECIFIED TOLERANCES

TO FOLLOW ISO-2768-F

DIMENSIONS IN MILLIMETRES

ARBORTECH INDUSTRIES PTY LTD

REV

DETAILS

APRVD DATE

A ISSUED FOR REVIEW

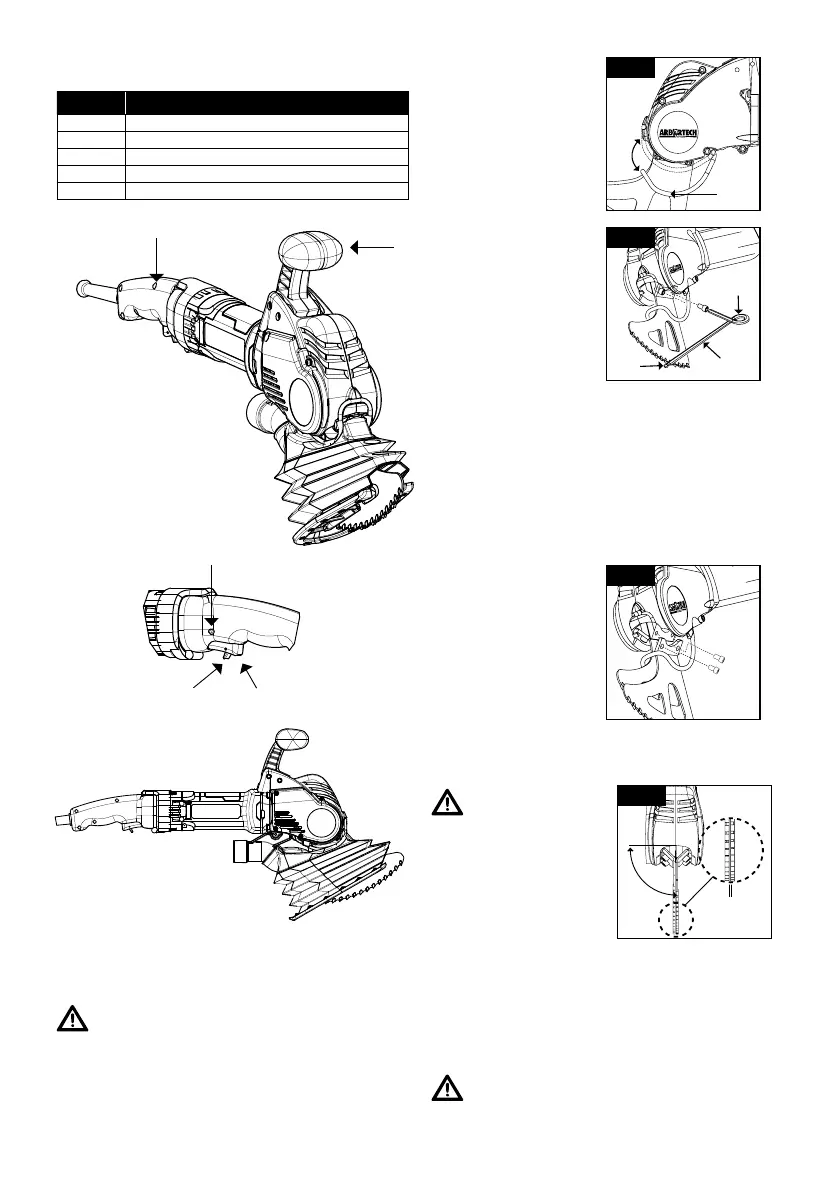

5. OPERATION

1) Setup

WARNING: It is recommended that the tool

always be supplied via a residual current device with a

rated residual current of 30mA or less.

The AS175 is supplied ready for operation. However in

some cases the blades may need to be changed to suit

the application.

Before changing blades,

the guard around the

blade mounts must be

levered gently out of its

groove at the front of the

tool and swung away to

give access to the cap

screws. (See Fig.1)

Guard

Fig.1

Use the “Ian key”

supplied to loosen and

remove the cap screws

securing the blades, then

remove the blades as

shown in Fig.2.

Ian Key

Fig.2

Hold near

end

Torque

indicator

coil

Select the correct blades for the cutting task and mount

each with their cap screws . Verify that the surfaces of

the blade mounts, conrod thread and screws are clean

and free of grit or lubricant before fitting. Ensure the

guard can be closed before fixing the blades to the

conrod (See Fig.2).

NOTE: Always use matched pairs of blades. Never

mix used blades with new blades. Use only the bolts

supplied with the tool.

Use the “Ian key” (see

Fig.2), to tighten the

blade mounting screws

until the torque indicator

coil deflects sufficiently

so that the sides meet.

The “Ian Key” will tighten

the bolts to the required

18Nm (13.2 ft lb).

Fig.3

NOTE: Blades are a wearing part. In normal

operation, blade life may vary with the hardness of

materials cut.

CAUTION:

Do not operate the tool if the

blades are loose. Operation

with loose blades will severely

damage the blade mount &

bolts requiring repair.

Check that the teeth of the

blades are lightly contacting,

or within approximately

1.5mm (1/16”) of contacting

each other (Fig.4).

Fig.4

90

o

1.5mm Max

(1/16”)

If the gap between the blades is too large, remove and

gently bend inward to adjust the gap.

Ensure that both blades are aligned vertically to the tool

(See Fig.4).

CAUTION: If the blades rub against each other

anywhere other than within 25mm/1” of the cutting

edge, or contact force is high, it is possible to overload

the tool and cause premature belt wear.

Loading...

Loading...