11

Field Wiring - Continued

Limit Control Operation

1.

MAIN POWER SUPPLY: Depending on model

designation, the electric Hydronic Block may be

energized by alternating current service entrances: 240

volt single phase 50 or 60 cycle 3 wire plus ground.

Wire size see Table 1. Sizes listed for various capacity

units include total amperes necessary to operate

elements, circulator and zone valves where used. Wire

sizes specied conform to Canadian Electrical Code

(Canada) or National Electric Code (USA) and include

derating for ampacity and temperature. Use copper

wire only. Check state and local requirements.

A. Read data name plate before connecting unit.

Electrical connections are provided and located for

proper installation.

B. Use only copper wire of proper size and make sure

all terminations are tight. Do not use aluminum

wire.

2.

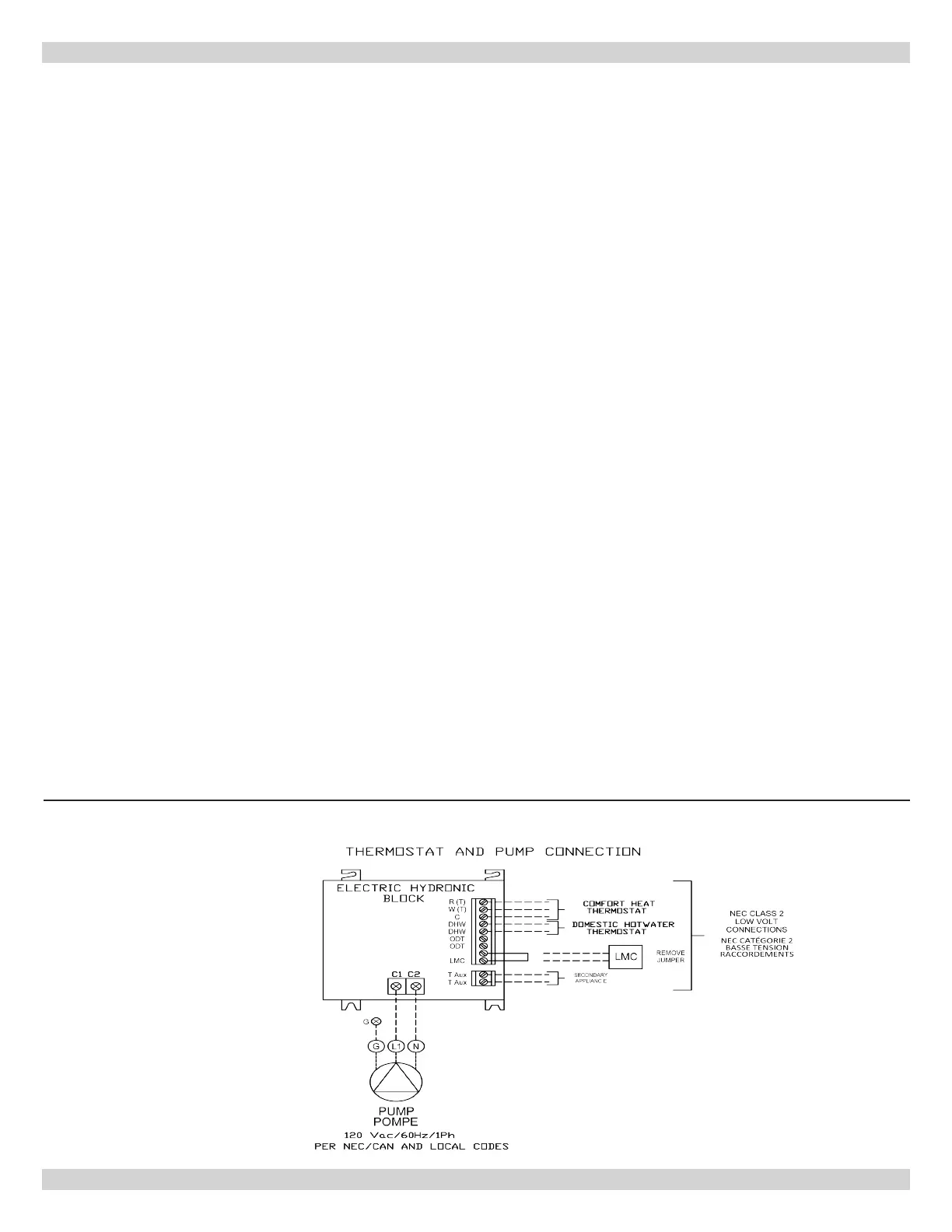

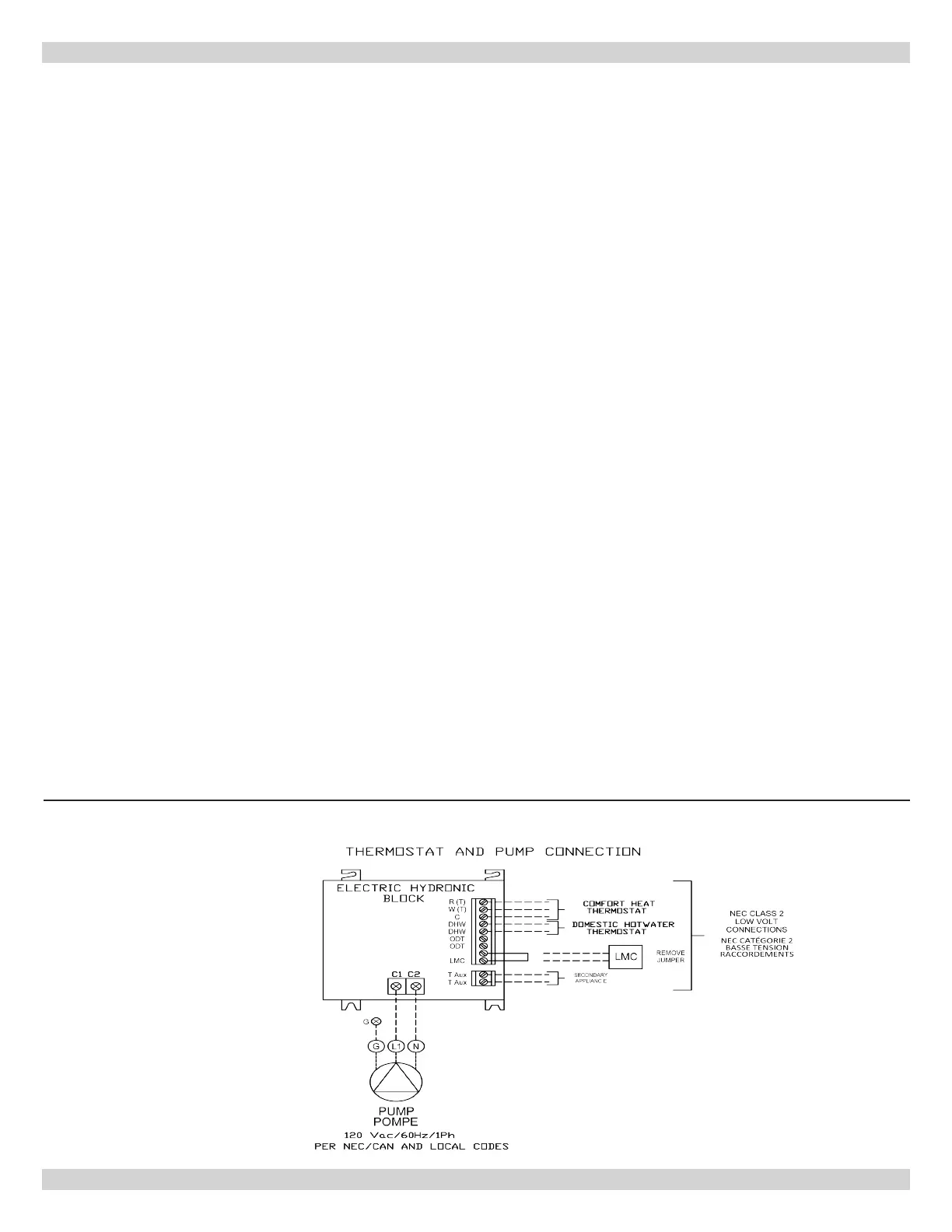

CIRCULATOR POWER SUPPLY: Terminals identied

as C1(L) and C2(N) at bottom of control panel (Figure

6) shall be used to supply one circulator pump

power. Circulator motor shall not be larger than 1/6

horsepower with maximum 5.0 amp rating. Wiring from

control panel to the pump should have insulation rated

75°C. Circuit protection is provided by 15 amp breaker

on boiler.

NOTE: If circulator pump is larger than maximum size

listed above, separate circulator pump relay must be

provided with separate overload protection. Where more

than one circulator is used for zoning, it must be installed

and protected according to approved electrical codes.

ELECTRICAL CONNECTIONS

Wiring On Control

• PUMP: Connect only 120 Vac 1/6 hp (maximum) pump

to terminals C1(L) and C2(N) on controller. Ground

screw is located on control panel. Strip wire ends before

inserting into terminal block. Tighten terminal screws.

Do not use pump rated greater than 5 amps!!

• THERMOSTAT: Two or three wire thermostat capable.

Terminals R(T), W(T) and C are provided. Two wire

thermostat use R(T) and W(T). Three wire thermostat

also use terminal C. See Figure 6. Do not apply

external power source to terminals!! Strip wire ends

before inserting into terminal block. Tighten terminal

screw clamps.

Thermostat Installation

1.

Install thermostat on inside wall ve feet above oor.

2.

NEVER install thermostat on outside wall.

3.

Do not install thermostat where it will be affected by

sunlight, drafts, televisions, lighting xtures, hot or

cold pipes, replaces, or chimneys.

4.

Instructions for nal adjustment of thermostat

(adjusting heating anticipator, calibration, etc.) are

packaged with thermostat.

5.

Recommended setting for heating anticipator is

0.1 amps.

Note: Argo AT Boiler will work with standard and

programmable setback thermostats.

Figure 6 - Thermostat and Pump Connection

Loading...

Loading...