10

ELECTRICAL CONNECTIONS

Boiler Wiring

NOTICE

Boiler is not designed for use of aluminum wiring.

Boiler failure can occur if aluminum wiring is used.

1.

Argo Electric Hydronic Boilers are pre-wired for use

with 240-volt, 3 wire, single-phase, 50/60-hertz power.

For reduction in boiler capacity when line voltage is less

than 240 volts see Table 1 page 6.

2.

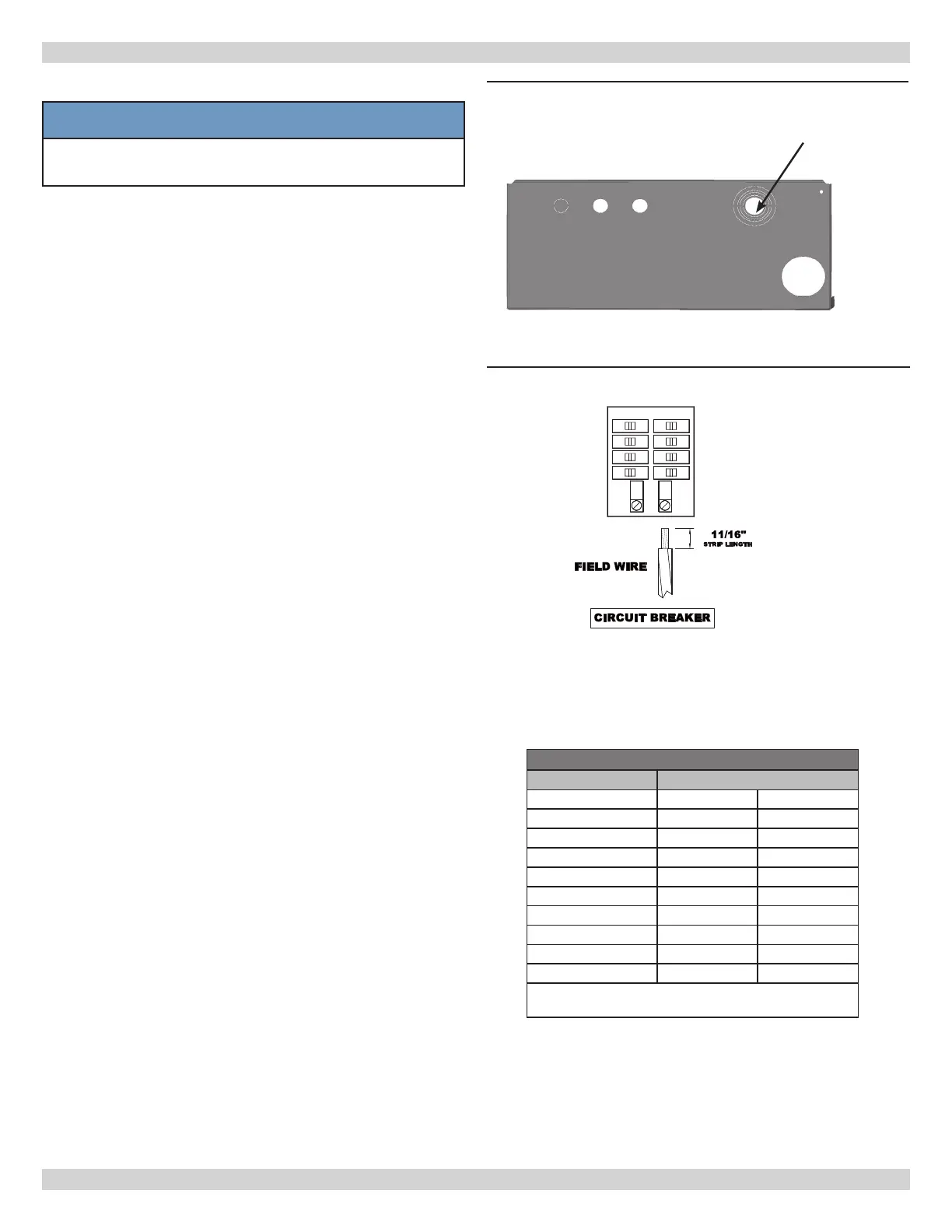

Opening provided in jacket bottom panel for eld wiring,

refer to rating chart for recommended wire sizes. See

Figure 4 for stepped Electrical Knock-out.

3.

Electrical wiring shall be in accordance with

requirements of authority having jurisdiction. Refer to:

• Canada - Canadian Electrical Code, CSA C22.1 Part 1,

Safety Standards for Electrical Installations.

• USA - National Electrical code, ANSI/NFPA 70.

4.

Verify nameplate rating and check related codes to

properly size conductors, switches and over current

protection.

5.

Stepped knockout is provided on bottom of cabinet for

different voltage connections. Wire connections refer

Figures 8 and 9 or wiring diagram on inside of boiler

front cover.

6.

All circuit breakers or disconnects ahead of boiler must

be OFF. Turn boiler integral breakers off at this time as

well. Remove boiler front cover by removing 4 screws

from top and sides.

7.

Boilers used in multiple zone system, zone valves

must be powered from independent source and have

electrically isolated end switches or isolating relays

wired in parallel to boiler thermostat terminals. Do not

attempt to power zone valves from transformer in

boiler control system.

Wire Classes - Table 2

Number of Concentric Strands

Wire Size AWG Class B Class C

10 7 19

8 7 19

6 7 19

4 7 19

3 7 19

2 7 19

1 19 37

1/0 19 37

2/0 19 37

Class B - Power cables

Class C - Power cables where more exibility is desired

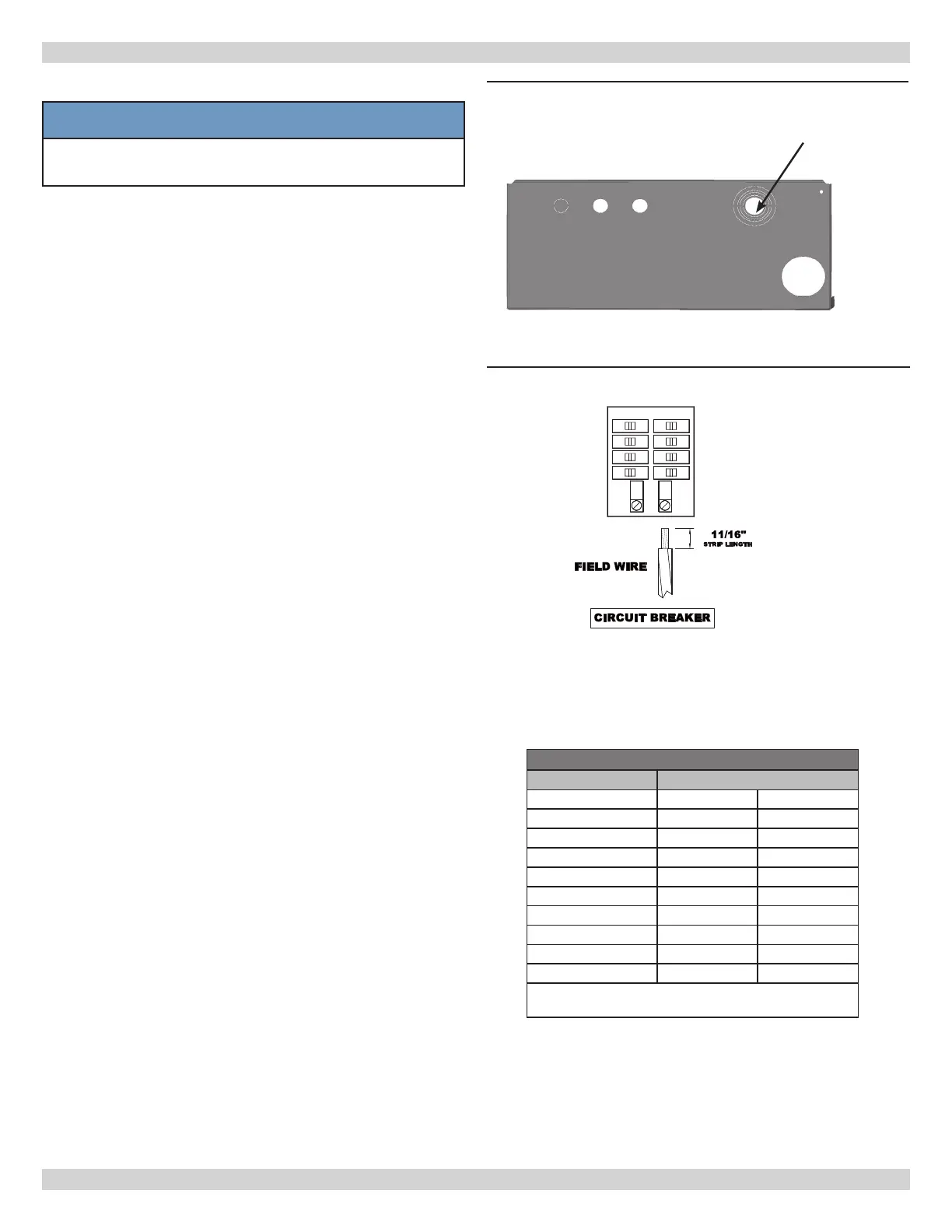

Field Wiring

• All Field wiring shall be in accordance with NEC or CEC

standards.

• Minimum Circuit Ampacity (MCA) and recommended

Maximum Over-current Protection (MOP) are listed on

nameplate of unit, see Table 1.

• Use Copper conductors only.

• Use only Class B or C Stranded wire. See Table 2.

• Wire Strip Length: 11/16” (Minimum). See eld wiring

diagram. See Figures 9 and 10.

• Wire must be fully inserted into terminal block.

• Field terminal wire lugs shall be securely tightened.

• Do not use wire grease on wire termination

connections. This will change torque properties.

Figure 4 - Stepped Electrical Knock-outs -

Jacket Bottom

Figure 5 - Field Wiring Diagram

Field Wiring

Entrance

Loading...

Loading...