8

Circulating System

• Design system as primary/secondary piping. Operate

system with maximum output temperature of 180ºF

(82°C) or lower and temperature rise across the unit of

20ºF (11°C) or lower. Refer to tables below and Figures

2 & 3.

• Return water temperature must be higher than room

temperature in which boiler is installed to prevent

condensation.

“AT” Series - 2 Element Boiler

KW Capacity Minimum Flow Rate (GPM)*

6 2.0

8 2.7

10 3.4

12 4.1

“AT” Series - 4 Element Boiler

KW Capacity Minimum Flow Rate (GPM)*

12 4.1

16 5.5

20 6.8

24 8.2

* Flow rate based on 20°ΔT

Connecting Supply And Return Piping

1.

Hot water boilers installed above radiation level must

be provided with low water cutoff device either as part

of boiler or at time of boiler installation.

2.

When boiler is connected to heating system utilizing

multiple zone circulators, each circulator must be

supplied with ow control valve to prevent gravity

circulation.

3.

Reduced pressure back ow preventer must be present

under provisions required by Environmental Protection

Agency, (EPA).

4.

Manufacturer requires plumbing arrangements as

illustrated in Figures 2 & 3. Inlet or return pipe is

located at bottom of unit. Reverse ow will result in

noisy operation and cause very early element failure.

Drain cock is to be located at lowest point of piping.

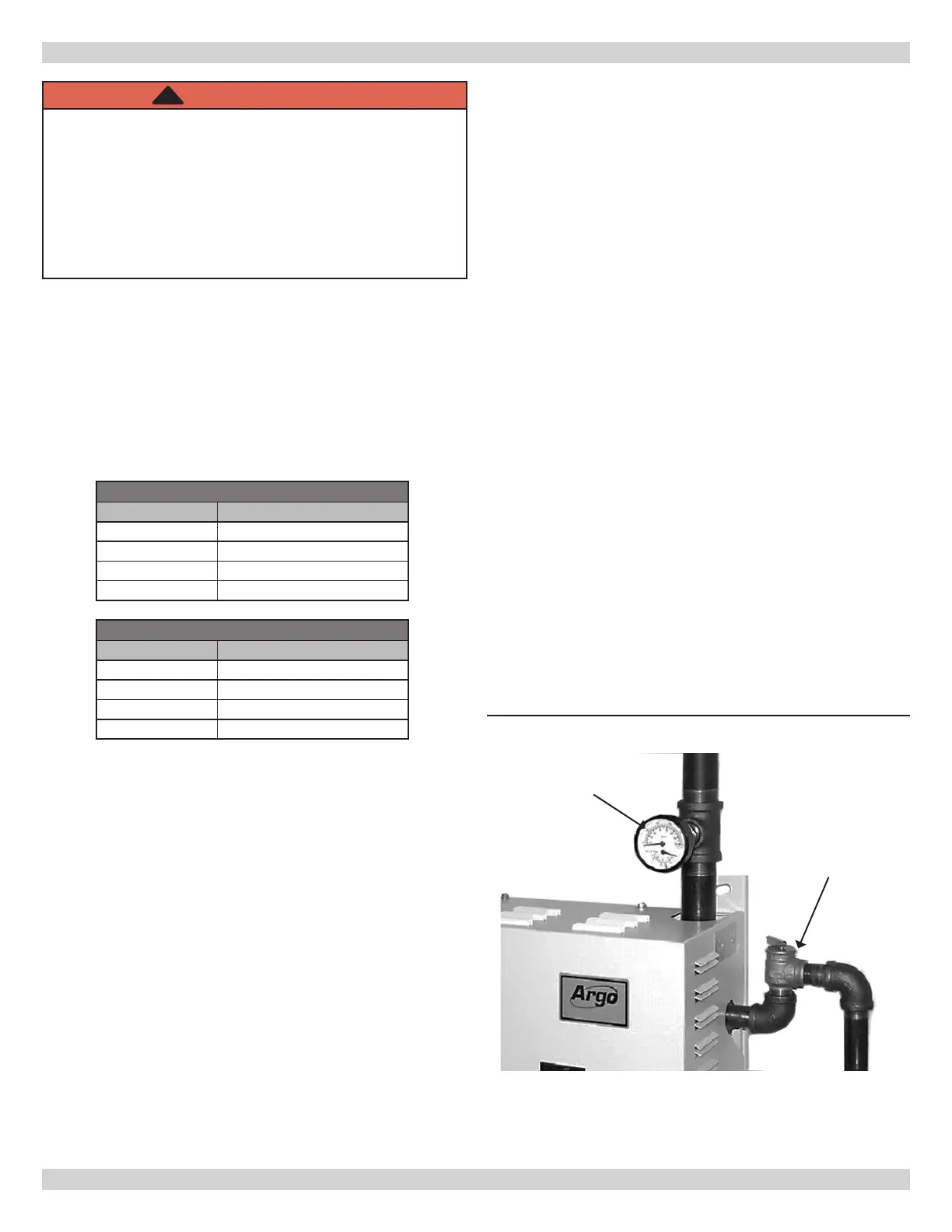

HYDRONIC PIPING

5.

Outlet or supply pipe line to radiation is located at top

of unit. Combination temperature pressure (altitude)

gauge is provided with each unit and should be

installed close to boiler outlet. It is important the gauge

sensor be completely immersed in owing water to

assure correct temperature readings.

6.

Install gate valves at locations shown in Figures 2 &

3, so any boiler servicing requiring removal of water

can be done quickly and easily. Not illustrated but

recommended is installation of air vents at high points

of hydronic system to reduce initial start up time and

help avoid element burnout during entire life of heating

system.

7.

Safety relief valve is supplied with each Electric

Hydronic Block and must be installed vertically. Install

at location and discharge direction shown using pipe

nipple and elbow supplied. See Figure 1. Add piping so

any water discharged will not damage boiler or other

system components.

8.

For further piping information refer to Hydronics

Institute (AHRI) manual (Installation Guide

for Residential Hydronics).

9.

Pipe the discharge outlet of the safety relief valve

within 6" of the oor.

Figure 1 - Safety Relief Valve

Safety Relief

Valve

Pressure

Gauge

WARNING

Fire, explosion, asphyxiation, burn, scald and

electrical shock hazard. System design must

incorporate primary/secondary piping to allow boiler

pump to prepurge and post purge the unit before

and after energizing the heating element. Shortened

element life and/or opening of safety relief valve

could occur. Failure to follow these instructions could

result in death or serious injury.

!

Loading...

Loading...