3

Installation site selection - Indoor unit

AVOID

• Direct sunlight.

• Nearby heat sources that may affect unit performance.

• Areas where leakage of flammable gas may be expected.

• Locations where large amounts of oil mist may occur (such as

in kitchen or near factory equipment) because oil contamination

can cause operation problems and may deform plastic surfaces

and parts of the unit.

• Unsteady locations that will cause noise or possible water

leakage.

• Locations where the remote control unit will be splashed with

water or affected by dampness or humidity.

• To make holes in areas where electrical wiring or conduits are

located.

DO

• Select an appropriate position from which every corner of the

room can be uniformily cooled.

• Select a sufficiently strong location to support the weight of the

unit.

• Select a location where tubing and drain hose have the shortest

run to the outside.

• Allow access for operation and maintenance as well as

unrestricted air flow around the unit.

Installation site selection - Outdoor unit

AVOID

• Heat sources, exhaust fans.

• Direct sunlight.

• Damp, humid or uneven locations.

• To make holes in areas where electrical wiring or conduits are

located.

DO

• Choose places as cool as possible and well ventilated.

• use lug bolts or equal to bolt down the unit, reducing vibration

and noise.

ADDITIONAL MATERIAL REQUIRED FOR INSTALLATION (NOT SUPPLIED)

●

Deoxidized annealed copper tube for refrigerant tubing connecting the units of the system; it has to be insulated with foamed polyethylene

(min. thickness 8mm).

●

PVC pipe for condensate drain pipe (ø int.18mm) in lenght suitable to let the condensate flow into the outside drainage.

●

Anti-freeze oil for flare connections (about 30g.).

●

Electric wire: use insulated copper wires of size and length as shown in the table “ELECTRICAL DATA” and at paragraph “SYSTEM WIRING

DIAGRAMS”.

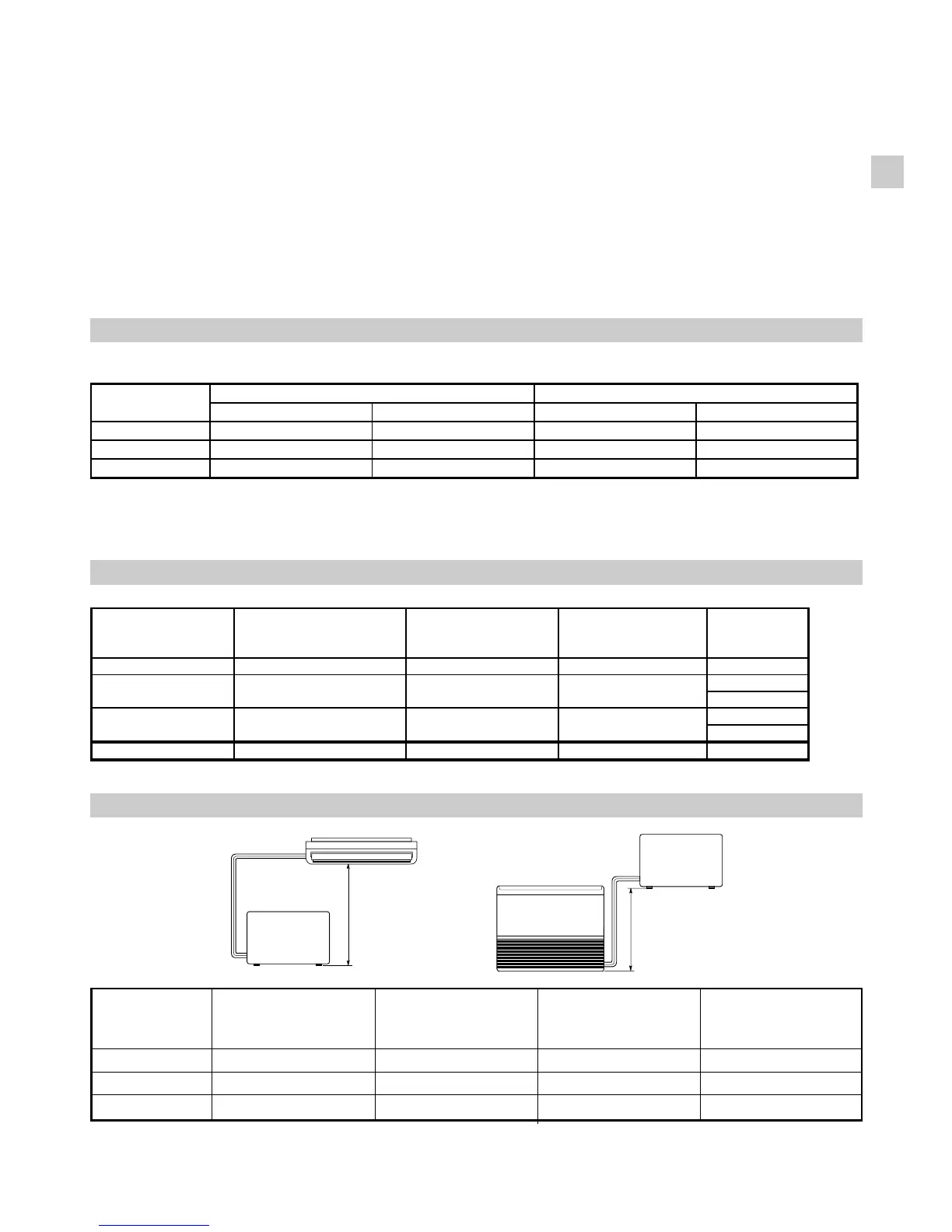

ELECTRICAL DATA

LENGTH, SIZE WIRES AND DELAYED FUSE

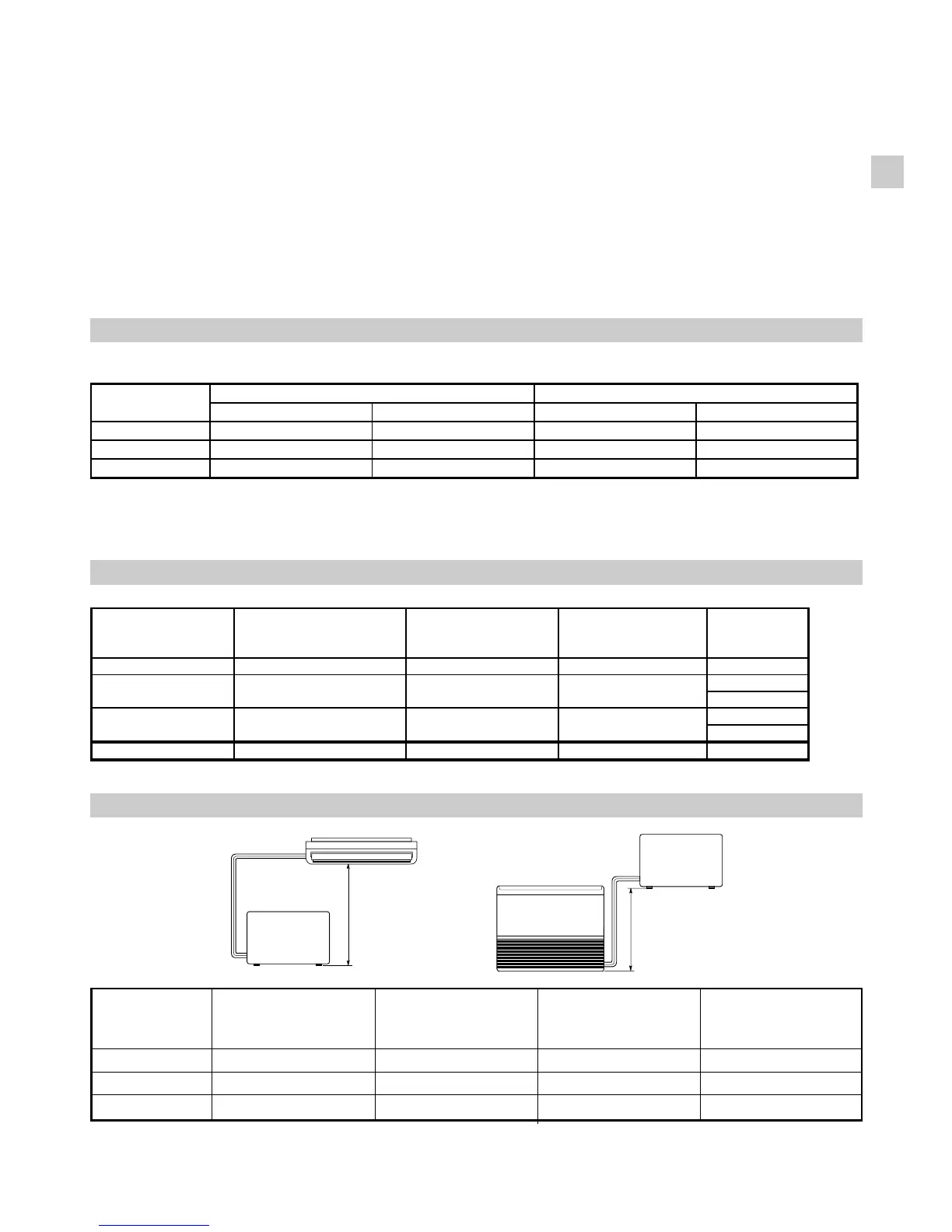

TUBING LENGTH AND ELEVATION DIFFERENCE LIMITS

(go on page 5)

EG

H

H

FC38AL 7,5 15 7 12

FC52AL 10 25 15 20

FC64AL 12,5 20 15 120

MODEL

MAX. ALLOWABLE LIMIT OF TUBING LIMIT OF ELEVATION REQUIRED AMOUNT OF

TUBING LENGTH AT LENGTH DIFFERENCE ADDITIOONAL

SHIPMENT H REFRIGERANT

(m) (m) (m) (g / m)*

* For every meter of tube more than standard lenght at shipment, add refrigerant as shown in the table. No additional charge

of compressor oil is necessary.

OUTER DIAMETER MIN. THICKNESS OUTER DIAMETER MIN. THICKNESS

FC38AL 6,35 mm 0,8 mm 9,52 mm 0,8 mm

FC52AL 6,35 mm 0,8 mm 12,7 mm 0,8 mm

FC64AL 9,52 mm 0,8 mm 15,88 mm 0,8 mm

Loading...

Loading...