22 /

MAINTENANCE

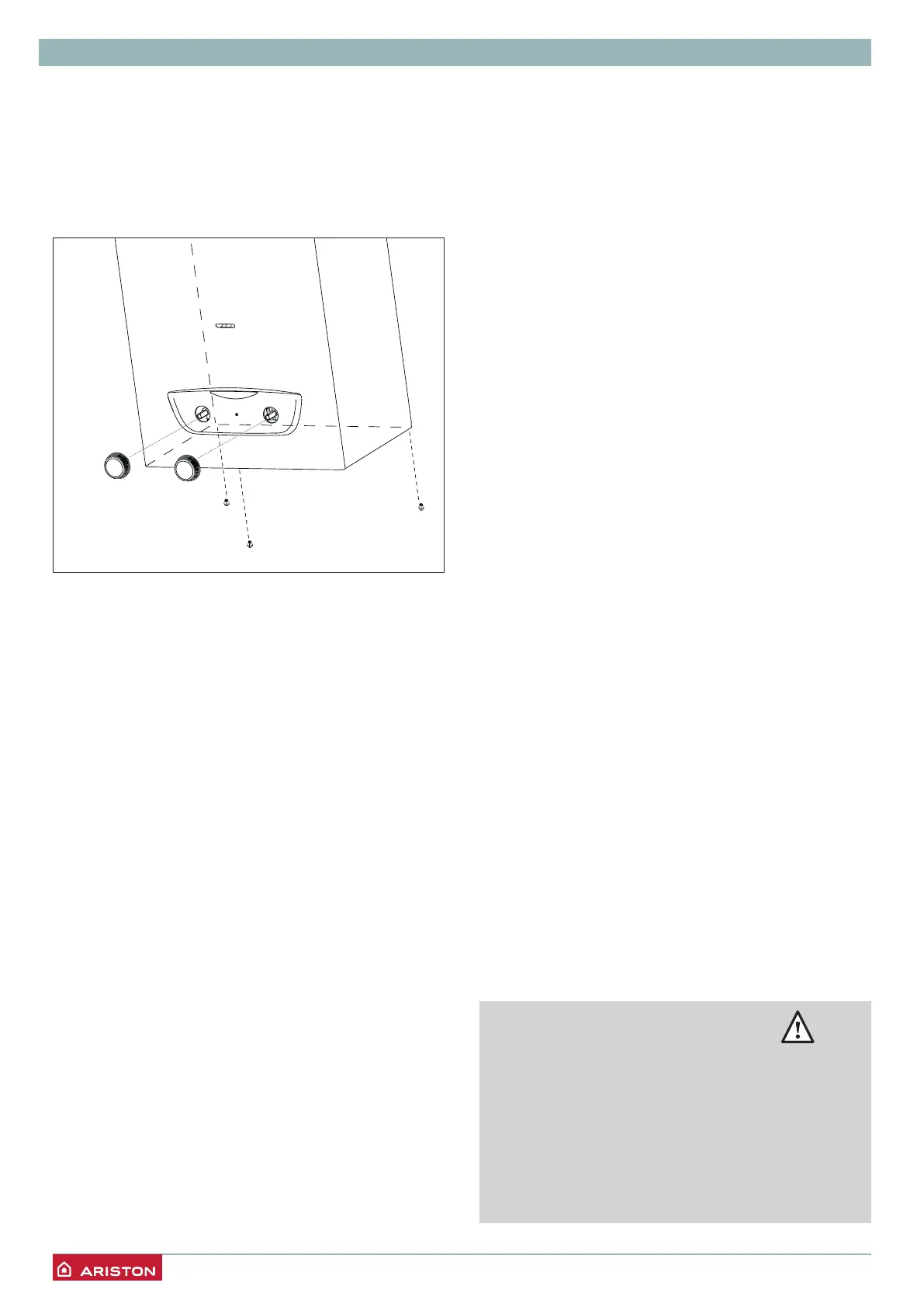

Instructions for opening the casing and performing

an internal inspection

Beforeperforminganyworkontheappliance,removethe

batteriesandclosethegasvalve.

Toaccesstheinsideoftheappliance,youneedto:

-Removetheknobs

-Removethethreescrews

WARNING!!

NEVER TAMPER WITH OR DECOMMISSION THE

FLUE GAS SENSOR. THIS COULD AFFECT THE

PROPER OPERATION OF THE APPLIANCE.

POOR DRAUGHT CONDITIONS COULD

CAUSE EXHAUST GAS BACKFLOW INTO THE

INSTALLATION ROOM.

HAZARD OF CARBON MONOXIDE

INTOXICATION.

Maintenanceisanessentialpartofthesafeandefcient

operation of the appliance and ensures its durability.It

shouldbeperformedaccordingtotheinstructionsgiven

incurrentlegislation.

Beforebeginningmaintenancework:

- Removethebatteries

- Close the gas valve and the domestic hot water

systemvalve.

Aftertheworkhasbeencompletedtheinitialsettingswill

berestored.

General comments

IT IS RECOMMENDED THAT THE FOLLOWING

INSPECTIONS BE CARRIED OUT ON THE APPLIANCE

AT LEAST ONCE A YEAR:

1. Visuallychecktheoverallconditionoftheappliance.

2. Checkthesealsinthewaterpartand,ifnecessary,

replacethegasketsandrestorethesealtoperfect

workingorder.

3. Check the seals in the gas part and, if necessary,

replacethegasketsandrestorethesealtoperfect

workingorder.

4. Visually check the combustion and, if necessary,

disassembleandcleantheburner.

5. Following the inspection detailed in point “3”,

disassembleandcleanthecombustion chamber,if

necessary.

6. Following the inspection detailed in point “4”,

disassemble and clean the burner and injector,

if necessary. Remove oxide from the detection

electrodeusinganemerycloth.

7. Cleaningtheprimaryheatexchanger

8. Makesurethefollowingsafetydevicesareoperating

correctly:

-temperaturelimitsafetydevice.

-uegassafety

9. Makesurethatthefollowinggaspartsafetydevices

areoperatingcorrectly:

-absenceofgasoramesafetydevice(ionisation).

10. Check the efciency of the domestic hot water

production process (test the ow rate and

temperature).

11. Cleaningthelterincoldwaterinlet.

WARNING! THE APPLIANCE MUST NOT

BE PUT IN FUNCTION WITHOUT FILTER.

12. Perform a general inspection of the aplliance

operation.

Loading...

Loading...