Chapter 2: Installation

2X-A Series Installation Manual 31

Connections

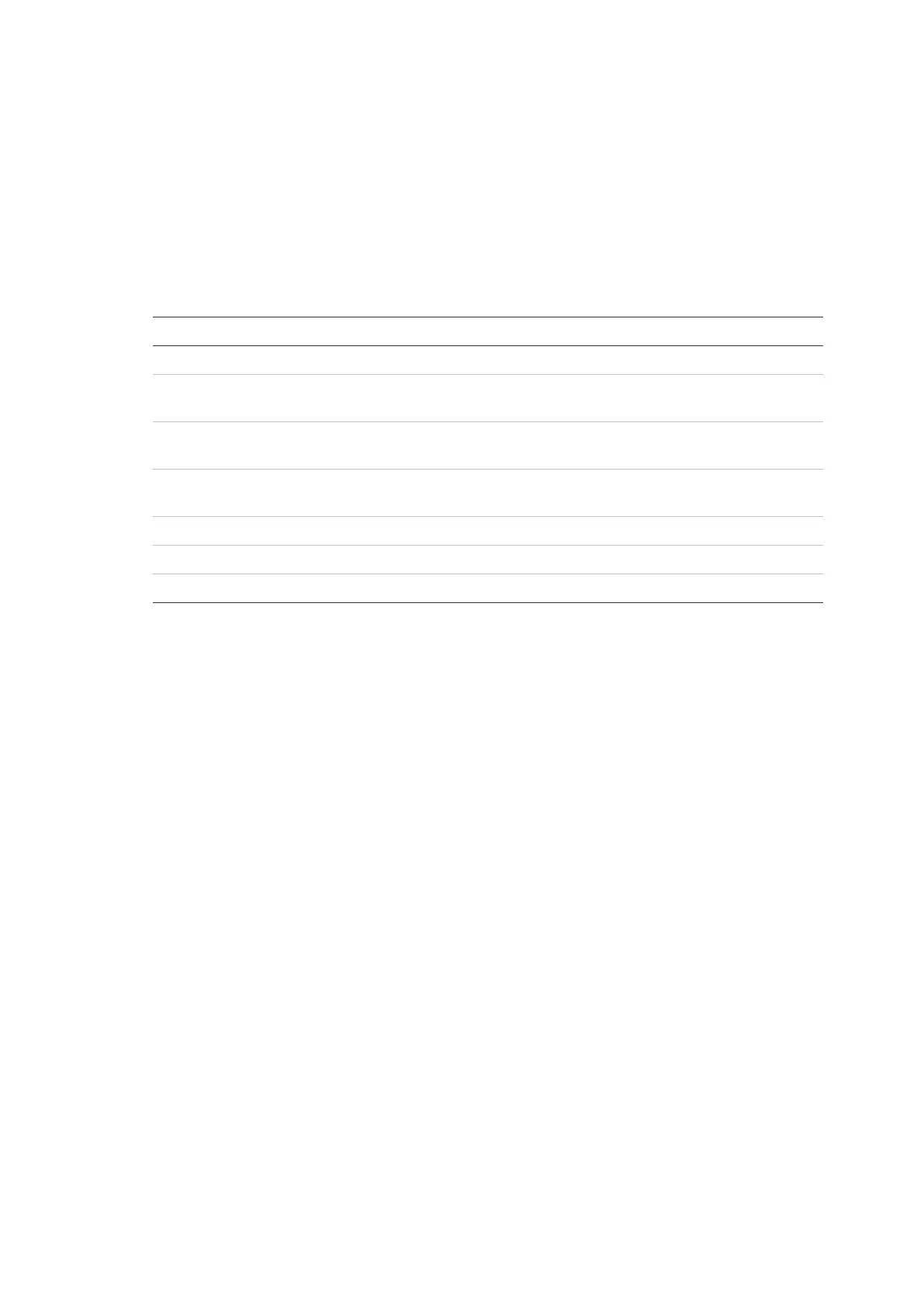

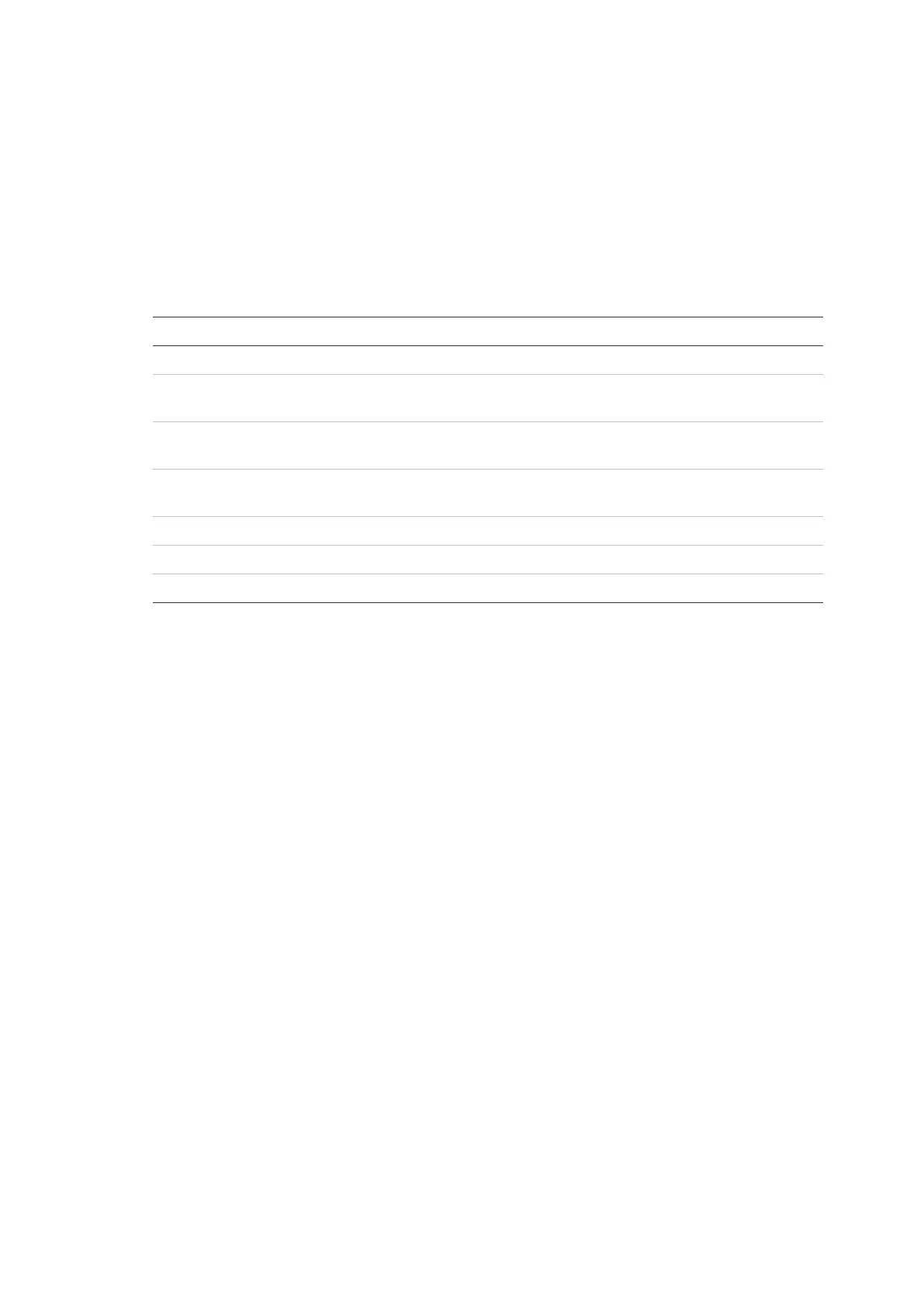

Recommended cables

Recommended cables for optimal system performance are shown in the table

below.

Table 14: Recommended cables

Cable requirements Max. cable length

3 × 1.5 mm

2

N/A

0.13 to 3.31 mm² (12 to 26 AWG) shielded or

unshielded twisted-pair (52 Ω and 500 nF max.) [1]

2 km [2]

(900

protocol)

0.13 to 3.31 mm² (12 to 26 AWG) twisted-pair

(52 Ω and 500 nF max.) [1]

2 km [2]

0.13 to 3.31 mm² (12 to 26 AWG) twisted-pair,

CAT5

1.2 km

CAT5, CAT5e, or CAT6 30 m [3]

Standard USB cable with A-B connectors 10 m

Accessory cable 2010-2-232-KIT [4] 3 m

Ω per wire.

[2] Maximum cable length depends on the

type of cable used and the loop load.

[3] Connect the control panel to an Ethernet

switch installed within 30 m if greater distances are

[4] This kit contains a 3 m cable and the 2010

-2-232-IB isolation board required for external

RS-232 device connections.

Other types of cable may be used subject to site-specific electromagnetic

interference (EMI) conditions and installation testing.

Using shielded loop cable

Shielded cable provides more flexibility in solving site-specific EMI problems and

is recommended, subject to following these guidelines:

• Use a multimeter to check that the shield is fully isolated from earth, the loop

positive, and the loop negative lines before connecting the shield to a single

point in the installation. The same isolation must be provided for any other

site wiring and loop cabling should avoid any known sources of EMI at the

site.

• Use the earth studs in the control panel cabinet for termination. See “Cabinet

and PCB layout” on page 19 for the location of the earth studs.

The PCB terminal earthing connections only improve noise immunity in very

specific environmental conditions. In some cases, leaving the earth fully

isolated provides the best protection against EMI.

Loading...

Loading...