installation &

operating instructions

Commercial pumps Series 4300, 4360 and 4380

Vertical In–Line pumps

4

1.0 introduction

This document contains specific information regarding the

safe installation, operating and maintenance of Vertical In-Line

pumps and should be read and understood by installing, oper-

ating and maintenance personnel. The equipment supplied has

been designed and constructed to be safe and without risk to

health and safety when properly installed, operated and main-

tained. The following instructions must be strictly adhered to.

If clarification is needed on any point please contact Armstrong

quoting the equipment serial number.

warning symbols

Safety instruction where an electrical hazard is involved.

Safety instruction where non-compliance would aect

safety risk.

Safety instruction relating to safe operation of the

equipment. (attention)

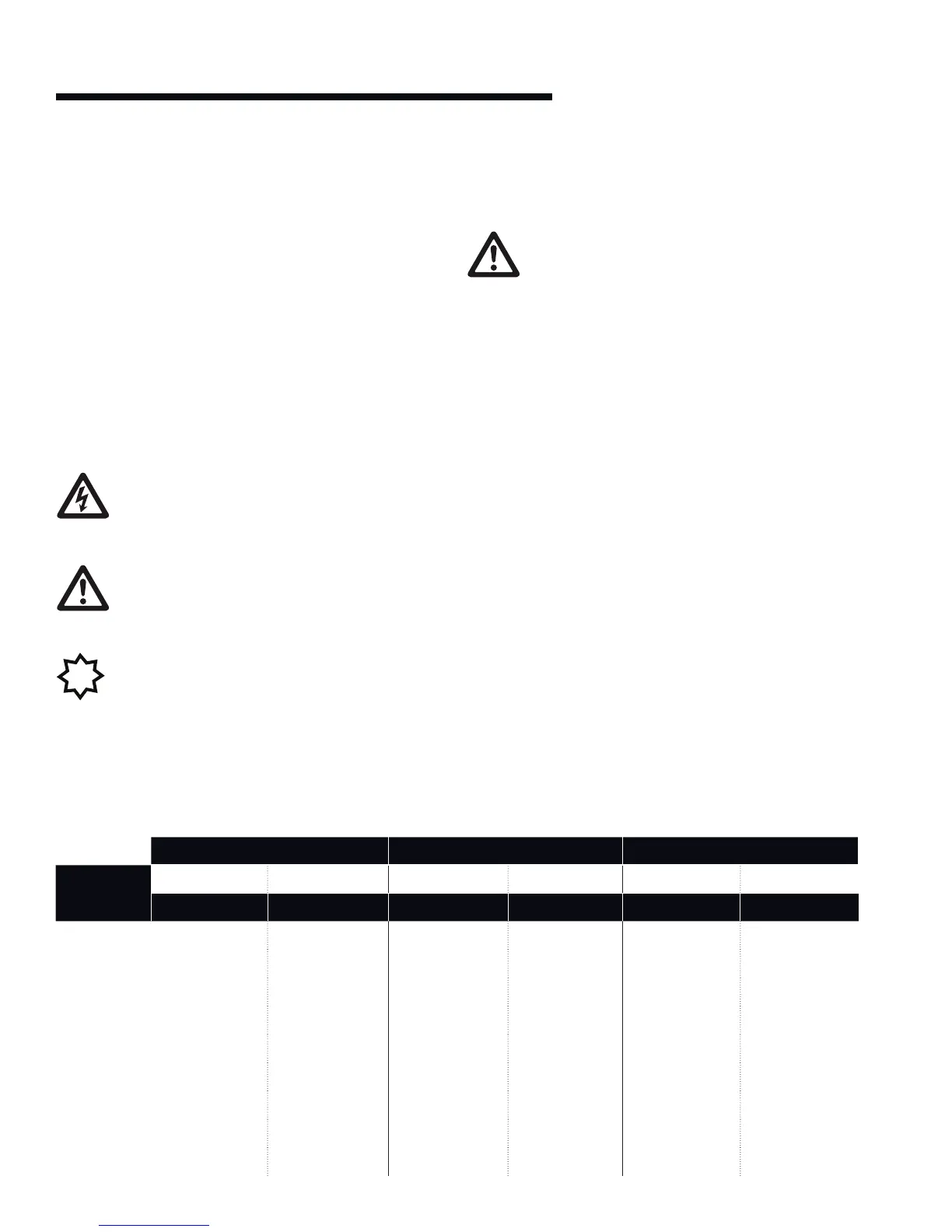

fig. 1 Noise levels.

1.1 instructions for safe use

No installation of this equipment should take place

unless this document has been studied and under-

stood. Handling, transportation and installation of

this equipment should only be undertaken by trained personnel

with proper use of lifting equipment. See later diagrams for lift-

ing advice. Refer to the pump nameplate for pump speed, pres-

sure and temperature limitations. The limits stated must not be

exceeded without written permission from Armstrong

.

1.2 temperature

Where under normal operating conditions the limit of

68°c/155°f (restricted zone) for normal touch, or 80°c/176°f

(unrestricted zone) for unintentional touch, may be experi-

enced, steps should be taken to minimize contact or warn

operators/users that normal operating conditions will be

exceeded. In certain cases where the temperature of the

pumped liquid exceeds the above stated temperature levels,

pump casing temperatures may exceed 100°c/212°f and not

withstanding pump insulation techniques appropriate mea-

sures must be taken to minimize risk for operating personnel.

1.3 noise levels

Typical Pumping Unit Sound Pressure Level, Decibels,

A-Weighted, at 1 m (3 ft.) from unit.

A

1200 rpm 1800 rpm 3600 rpm

frame

designation

odp tefc odp tefc odp tefc

hp dB-A hp dB–A hp dB–A hp dB–A hp dB–A hp dB–A

140 0.75 – 1 59 0.75 – 1 58 1 – 3 64 1 – 2 64 1.5 – 3 70 1.5 – 2 79

180 1.5 – 2 61 1.5 – 2 61 3 – 5 66 3 – 5 68 5 – 7.5 74 3 – 5 82

210 3 – 5 66 3 – 5 65 7.5 – 10 70 7.5 – 10 73 10 – 15 76 7.5 – 10 85

250 7.5 – 10 70 7.5 – 10 69 15 – 20 74 15 – 20 78 20 – 25 78 15 – 20 88

280 15 – 20 75 15 – 20 74 25 – 30 74 25 – 30 82 30 – 40 80 25 – 30 89

320 25 – 30 77 25 – 30 77 40 – 50 78 40 – 50 83 50 – 60 83 40 – 50 94

360 40 – 50 80 40 – 50 80 60 – 75 80 60 – 75 89 75 – 100 88 60 – 75 95

400 60 – 75 82 60 – 75 84 100 – 125 83 100 92 125 – 150 92 100 96

440 100 – 125 85 100 – 125 88 150 – 200 87 125 – 150 96 200 – 250 95 125 – 150 98

Loading...

Loading...