2

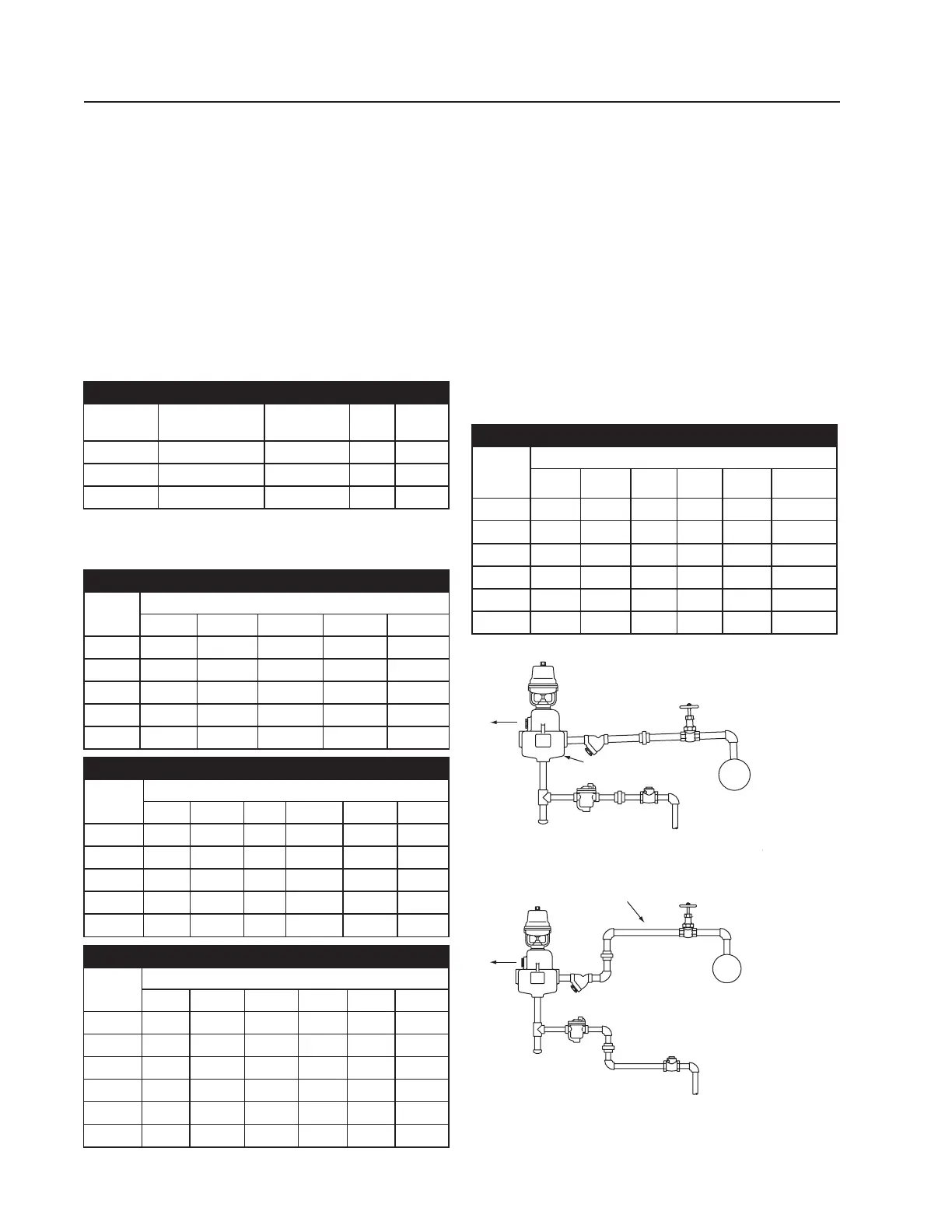

Step 3. Run the steam supply line from the steam

header to the humidifi er as indicated in Fig. 2-1. Observe

the following:

A. Take steam supply line from the top of the supply

main – never from the side or bottom. If several

humidifi ers take steam from a single supply line,

be sure to trap the end of the run-out with an Arm-

strong Trap of suitable size. If the steam supply is

very wet, install a drip pocket or separator ahead

of the humidifi er.

B. Size supply line in accordance with Table 2-1. If

the steam supply is 5 psi or less, it is advisable to

use one pipe size larger and reduce the pipe size

just ahead of the strainer and humidifi er.

C. Pitch the supply line in the direction of fl ow.

Humidifi er Piping

D. Expansion and Contraction. With average length

of supply line, the dimension change from hot to

cold should not exceed 2”. Provide piping with 3

elbows to get swing to take care of expansion and

contraction (See Fig. 2-2).

E. Clean piping. After running the supply line, blow

down at full steam pressure to eliminate dirt and

pipe cuttings.

F. A Pipe Strainer is furnished with each humidifi er.

Install (after blowing down supply line) as indi-

cated on drawing.

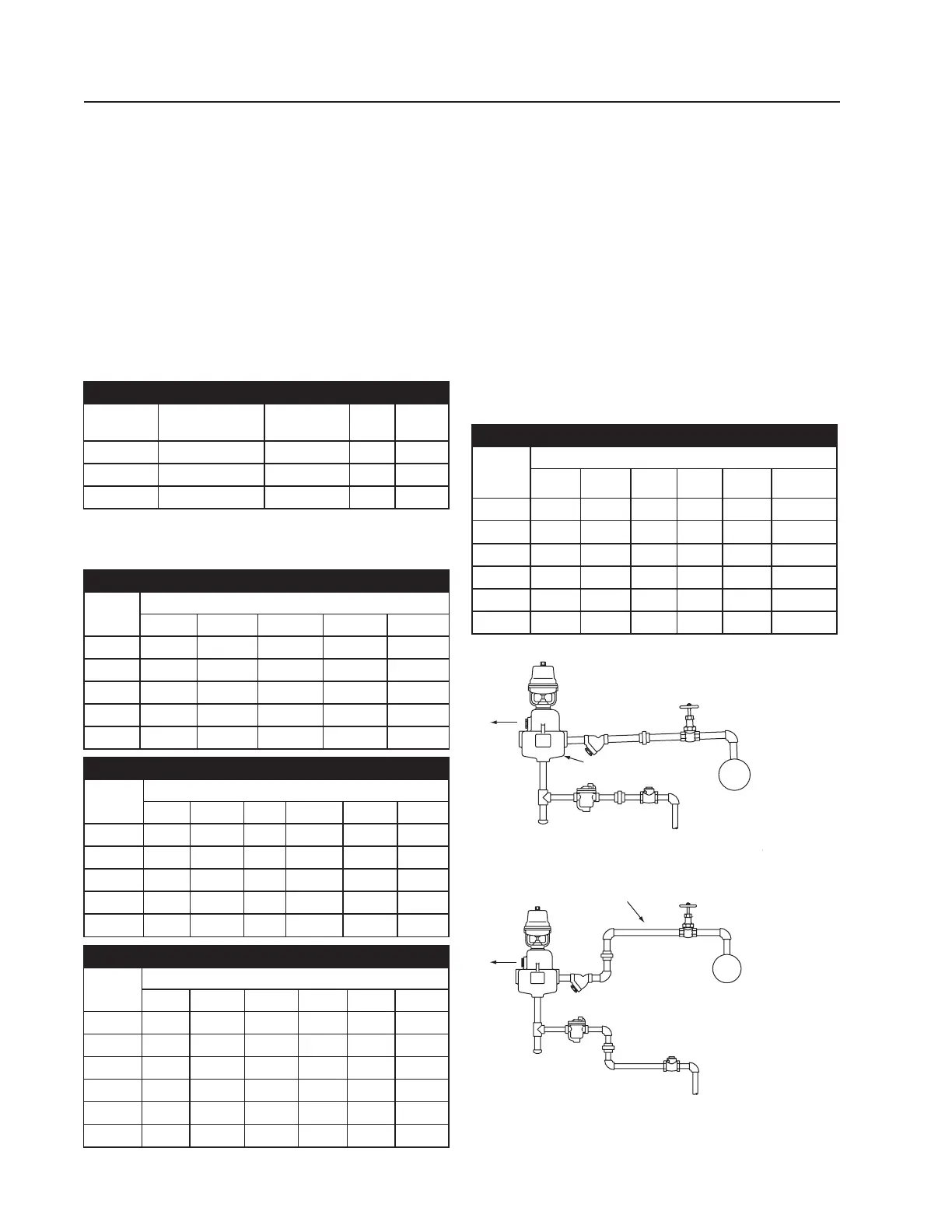

G. Swivel connections may be desirable – see

Fig. 2-2 and explanatory captions.

H. Pressure Reducing Valve. If required refer to

Fig. 3-1 and explanatory captions.

Table 2-1 Recommended Pipe Sizes

Humidifi er

Size

Supply Header

to Strainer

Steam Inlet

& Strainer

Drip

Leg

Trap

Piping

91 3/4” 3/4” 1” 3/4”

92 3/4” 3/4” 1” 3/4”

93 1-1/4” 1-1/4” 1-1/4” 3/4”

Steam Pipe Capacities

For computing ability of piping to deliver an adequate supply of steam to

humidifi er. Capacities shown are in pounds per hour.

Table 2-2 Steam Pipe Capacity at 5 psi

Pipe

Size in.

Pressure drop, psi per 100 ft. of pipe length

1/8 1/4 1/2 3/4 1

12431 44 54 62

1-1/4 52 68 97 120 140

1-1/2 81 100 150 180 210

2 160 210 300 370 430

2-1/2 270 350 500 610 710

Table 2-3 Steam Pipe Capacity at 15 psi

Pipe

Size in.

Pressure drop, psi per 100 ft. of pipe length

1/8 1/4 1/2 3/4 1 2

1 27 38 53 65 76 110

1-1/4 59 83 120 140 160 230

1-1/2 91 130 180 220 260 360

2 180 260 370 450 520 740

2-1/2 300 430 600 740 860 1210

Table 2-4 Steam Pipe Capacity at 25 psi

Pipe

Size in.

Pressure drop, psi per 100 ft. of pipe length

1/8 1/4 1/2 3/4 1 2

3/4 15 21 30 37 43 60

1 30 43 61 75 86 122

1-1/4 67 95 130 160 190 260

1-1/2 100 140 210 250 290 410

2 210 300 420 510 590 840

2-1/2 340 490 690 850 980 1380

Table 2-5 Steam Pipe Capacity at 50 psi

Pipe

Size in.

Pressure drop, psi per 100 ft. of pipe length

1/4 1/2 3/4 1 2 5

3/4 27 38 47 54 76 120

1 54 77 94 110 150 240

1-1/4 120 170 210 240 340 530

1-1/2 180 260 320 370 520 830

2 370 530 650 750 1060 1680

2-1/2 620 870 1070 1240 1750 2760

Figure 2-1.

Figure 2-2.

Strainer

Steam

Trap

Dirt

Pocket

Check

Valve

Take off top o

steam supply

To low

pressure return

Pitch down 1/2" in 10'

Typically pneumatically controlled humidifier installation.

Strainer

Steam

Trap

Dirt

Pocket

Check

Valve

To low

pressure return

Take off top of

steam supply

Pitch down

1/2" in 10'

Swivel connections shown above permit direction of discharge

to be altered easily. Loosen both unions, adjust direction, then

retighten unions.

Loading...

Loading...