506303-01 Page 19 of 40Issue 0938

Be sure that the pressure switch hose does not form a

trap to hold condensation that could form from the flue

gas. Hose may be cut shorter to avoid forming a trap, if

required.

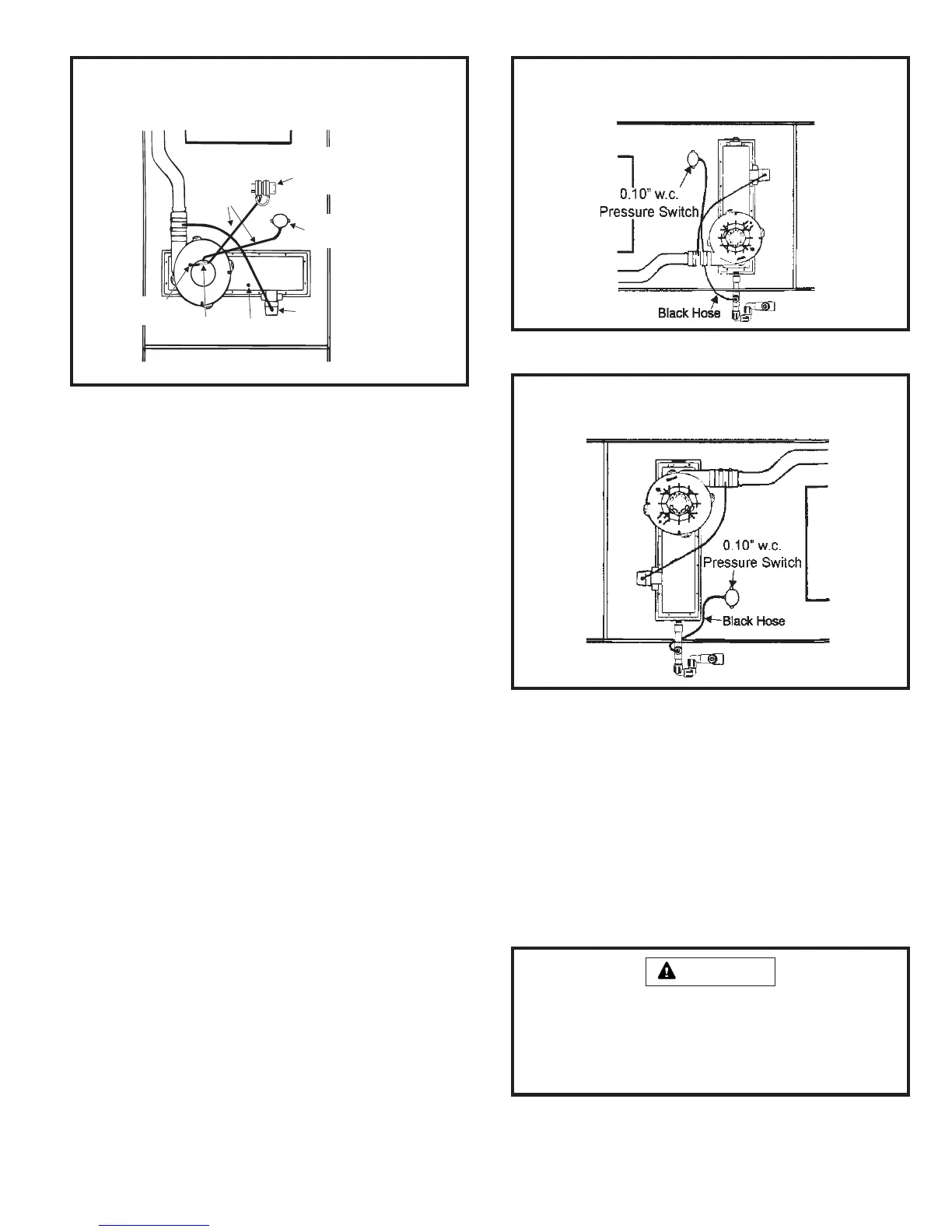

Horizontal Installation

The G2D93CT and G2D95CT units are shipped from the

manufacturer with a black hose having one end connected

to the 0.10” drain pressure switch and the other end shipped

loose. FOR HORIZONTAL INSTALLATIONS the loose end

MUST be connected to the external drain trap.

Route hose through gas line access hole in cabinet. Then

connect to 1/4" barbed fitting on drain trap assembly.

For right to left airflow installations, see Figure 28. For left

to right airflow installations, see Figure 29.

Be sure that the pressure switch hose does not form a

trap to hold condensation that could form from the flue

gas. Hose may be cut shorter to avoid forming a trap, if

required.

Circulating Air Supply

When the furnace is installed so that the supply ducts carry

air circulated by the furnace to areas outside the space

containing the furnace, the return air shall be handled by a

duct or ducts sealed to the furnace casing and terminated

outside the space containing the furnace.

When an air conditioning unit is used in conjunction

with the furnace, the evaporator coil must be installed

in the discharge (supply) air. Do not install an evaporator

coil in the return air; excessive condensation will occur

within the furnace.

CAUTION

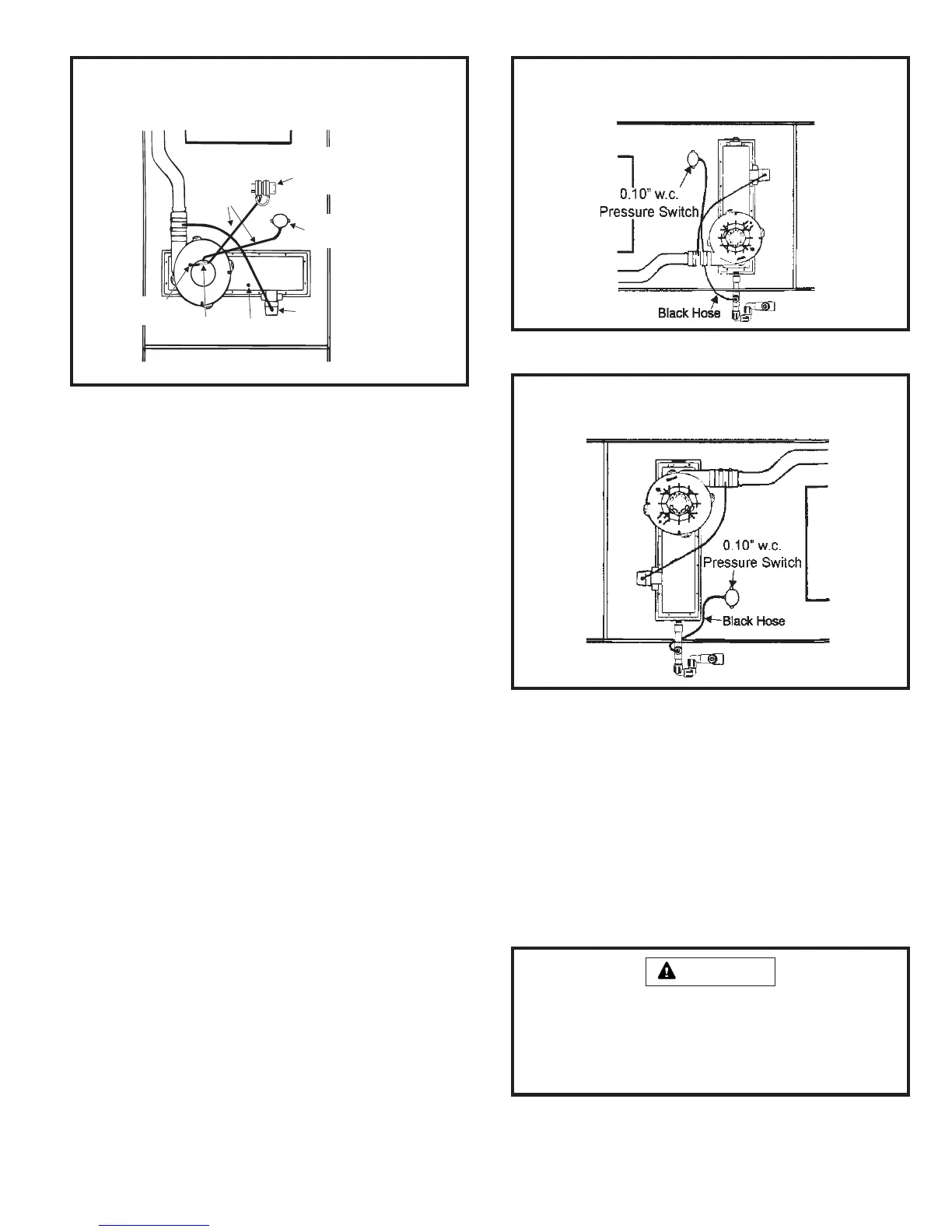

Pressure Switch Connection

Horizontal Installation – R to L Airflow

Figure 28

Pressure Switch Connection

Upflow Installation

Figure 27

Black

Hoses

Tee

(supplied)

Low Fire-High Fire

Pressure Switch

Assembly

Yellow Cap

Blower

Housing

Tap

Trap

0.10” w.c.

Pressure Switch

Pressure Switch Connection

Horizontal Installation – L to R Airflow

Figure 29

A return air duct system is recommended. If the unit is

installed in a confined space or closet, a return connection

must be run, full size, to a location outside the closet. The

air duct in the closet must be tight to prevent any entrance

of air from the closet into the circulating air.

If there is no complete return air duct system, the return air

connection must be sealed to the furnace casing and run, full

size, to a location outside the utility room or space housing the

furnace to prevent a negative pressure on the venting system.

Loading...

Loading...