506303-01

Page 20 of 40 Issue 0938

3. With the filter access opening toward the front of the

furnace, use sheet metal screws to fasten the rack(s)

to the side panel(s).

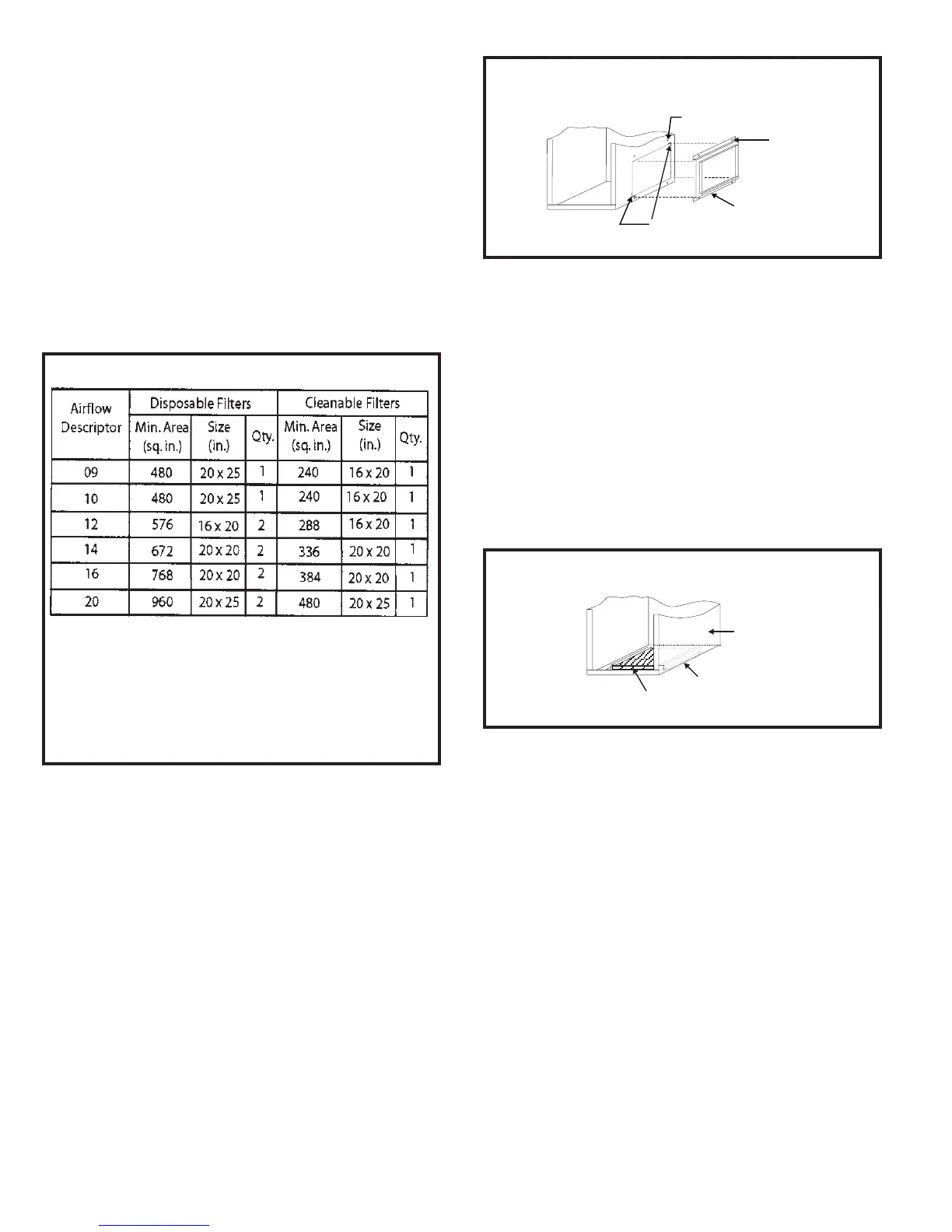

The filter slides in the rack from the front of the unit. Install

the filter(s) with the mesh side towards furnace.

Model #AFILTHA7 single side filter frame kit is available for

single side return air connection in installations requiring more

than 1600 CFM nominal air delivery. A bottom return filter kit

(model #AFILT529) is also available from the manufacturer.

Outlet Duct

For installations not equipped with a cooling coil, a

removable access panel must be provided in the outlet duct.

The opening should be accessible when the furnace is

placed in service. Smoke or reflected light may be observed

inside the casing to indicate the presence of leaks in the

heat exchanger. The cover for the opening shall be attached

in such a manner as to prevent leaks. The recommended

opening size is 6" x 14" for all sizes.

Filters

If a filter other than one supplied by the furnace manufacturer

is used, it must be sized according to information provided

in Table 3.

A filter rack and cleanable 16" x 25" x 1/2" filter are supplied

with the furnace. (Models designed for more than 1600 CFM

nominal air delivery include two of each.) The filter rack is

to be installed between the return air duct and the side of

the furnace.

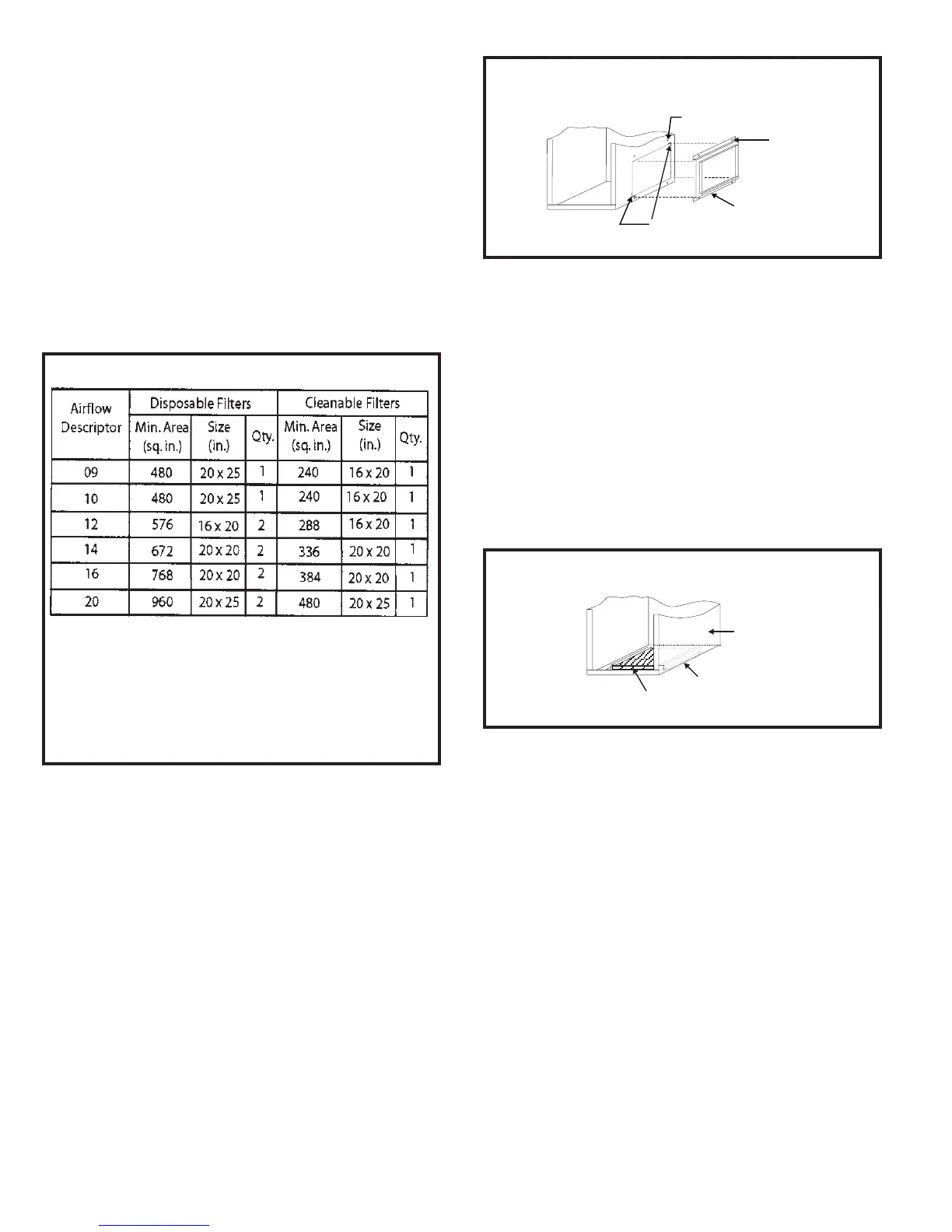

Refer to Figure 30 and the following instructions to install

the filter rack:

1. Using the corner embossments as a guide, mark and

cut a full-size opening in the side panel(s).

2. Using the filter rack as a template, mark and drill four

7/64” diameter screw holes in the side panel(s).

Other filter accessories are also available from the

manufacturer including a full line of indoor air quality products.

For information on these products, contact the local distributor.

Gas Supply and Piping

Refer to the furnace rating plate to make sure the furnace

is equipped to burn the gas supplied (natural or propane).

Gas supply piping should be installed in accordance with local

codes and the regulations of the utility. Piping must be of

adequate size to prevent undue pressure drop. Consult the

local utility or gas supplier for complete details on special

requirements for sizing gas piping.

Table 3

Minimum Filter Requirements

1. The Airflow Descriptor is the two digits following the “D”

(example: G2D93CT080D16C) or “V” (example:

G2D95CT080V16C) in the model number.

2. Areas and dimensions shown for cleanable filters are based on

filters rated at 600 feet per minute face velocity.

3. Typical filter sizes are shown; however, any combination of

filters whose area equals or exceeds the minimum area shown

is satisfactory.

Filter Rack Mounting Hole

Screw

Filter Rack

Corner Embossments

Front of Cabinet

Filter Rack Installation

Figure 30

Figure 31

Bottom Filter Location

Filter

Base

Side

Loading...

Loading...