www.armstrongfluidtechnology.com

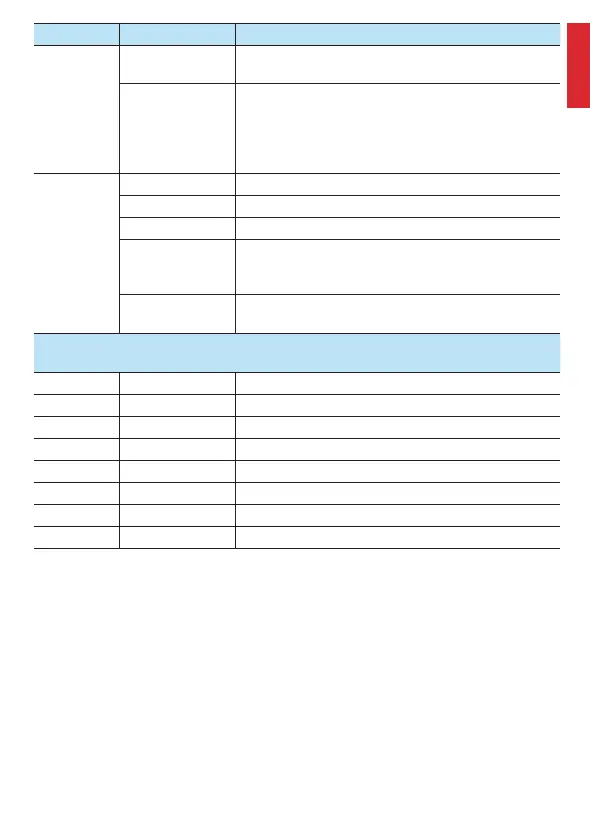

Fault Cause Action

Pump not

running

No operating

voltage

• Check the electrical system.

Rotor/shaft

blocked, digital: fast

LED flashes

• Isolate the pump from the power supply

• Remove the vent screw (see p. 43/44)

• Turn the shaft clockwise using a screwdriver (4mm)

• Screw in the vent screw

• Switch on the pump

Loud noises

(> 43 dB(A))

Air in the system • Bleed the system

Air in the pump • Bleed the pump (see p. 43/44)

Pump flow too high • Reduce the pump speed using the knob or button

Cavitation due to

insufficient supply

pressure

• Check the operating pressure of the system

• Increase the system threshold values

Foreign matter in

pump housing

• Clean the housing

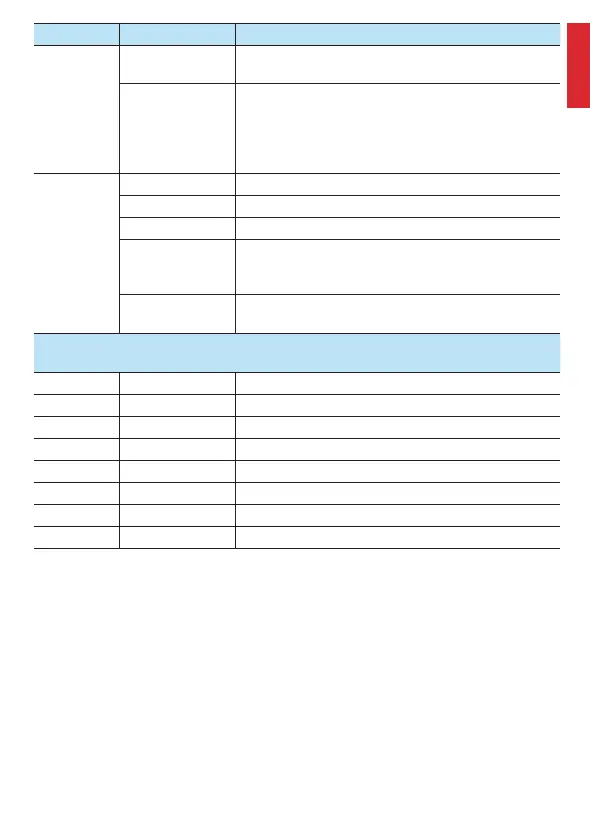

HEP Optimo/HEP Optimo (N)/

HEP Optimo Geo

E1 Overvoltage Ensure admissible voltage supply, then error will be eliminated

E2 Undervoltage Ensure admissible voltage supply, then error will be eliminated

E3 Blocked rotor Vent screw to unblock shaft manually, restart pump

E4 Dry running Open valve, fill medium, vent pump

E5 Overload Replace pump with pump with higher power motor

E6 Winding fault Remove supply voltage and replace pump

E7 Short circuit Remove supply voltage and replace pump

E8 Pump motor error Replace the pump

EN

47

Loading...

Loading...