Page 5 of

7

©ASCO, L.P. 160 Park Avenue, Florham Park, New Jersey 07932 www.asco.com

I&M No

V 9629 R9

All Ri

hts Rese

ved

2.5 SIL

Capability

2.5.1 Systematic

Integrity

The product has met manufacturer design process requirements of Safety Integrity Level (SIL) 3. These

are

intended to achieve sufficient integrity against systematic errors of design by the manufacturer. A

Safety

Instrumented Function (SIF) designed with this product must not be used at a SIL level higher than

the

statement without “prior use” justification by end user or diverse technology redundancy in the

design.

2.5.2 Random

Integrity

The solenoid valve is a Type A Device. Therefore when used the only component in a final

element

subassembly, a design can meet SIL 3 @ HFT=1 and SIL 2 @

HFT=0.

When the final element assembly consists of many components (solenoid valve, quick exhaust valve,

actuator,

isolation valve, etc.) the SIL must be verified for the entire assembly using failure rates from all

components.

This analysis must account for any hardware fault tolerance and architecture

constraints.

3 Installation and

Commissioning

3.1

Installation

•

The ASCO Solenoid valve must be installed per standard installation practices outlined in

the

Installation

Manual.

•

The environment must be checked to verify that environmental conditions do not exceed the

ratings.

•

The ASCO Solenoid must be accessible for physical

inspection.

•

Instrument Air Filtration: These solenoids are intended for use on clean, dry air or inert gas filtered

to

50 microns or better. To prevent freezing, the dew point of the media should be at least

18

°

F

(10

°

C)

below the minimum temperature to which any portion of the clean air or gas system could be

exposed.

Instrument air in compliance with ANSI/ISA Standard S7.3-1975 (R1981) exceeds the

above

requirements and is, therefore, an acceptable medium for these

valves.

•

It is the operator’s responsibility to only use design options such as latches, when it is safe to do so.

•

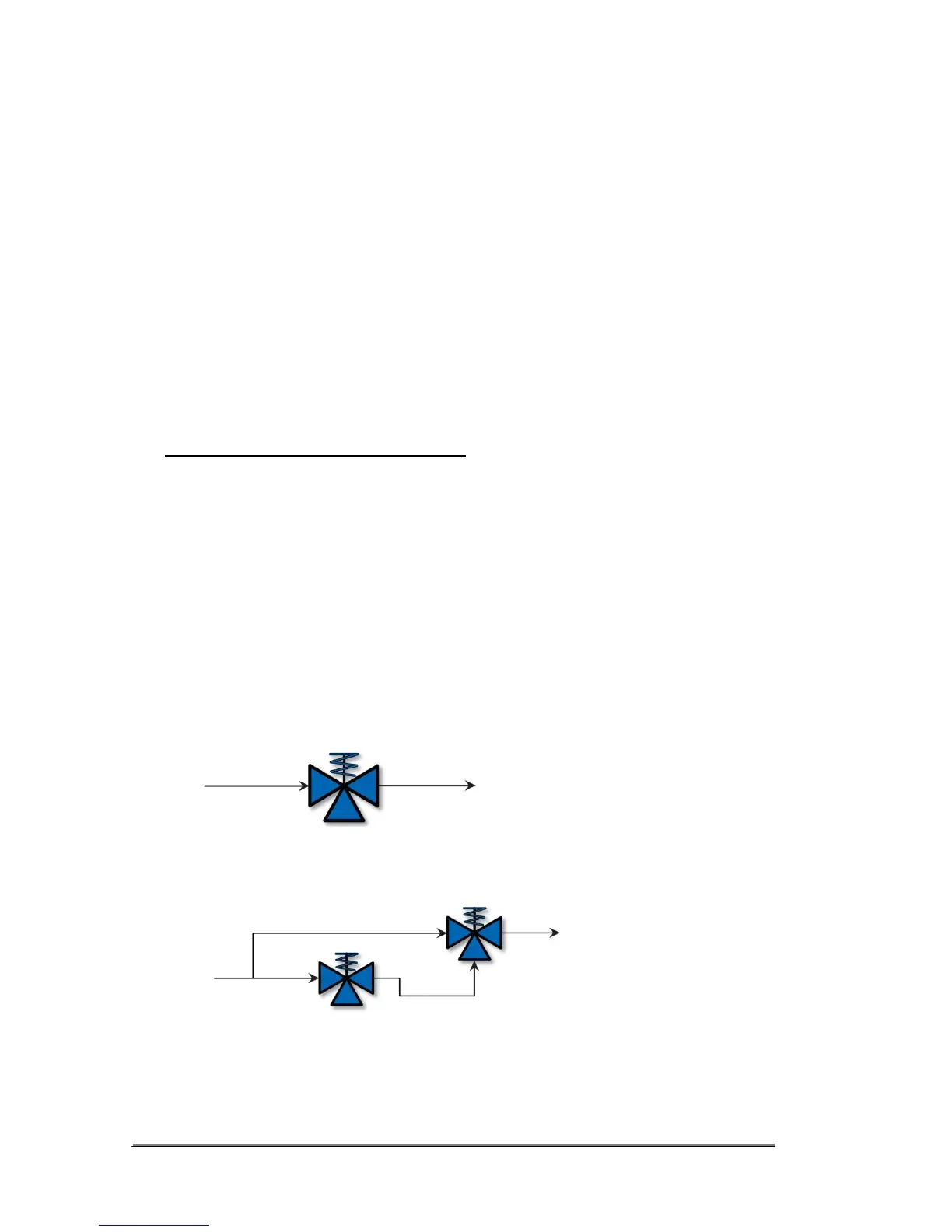

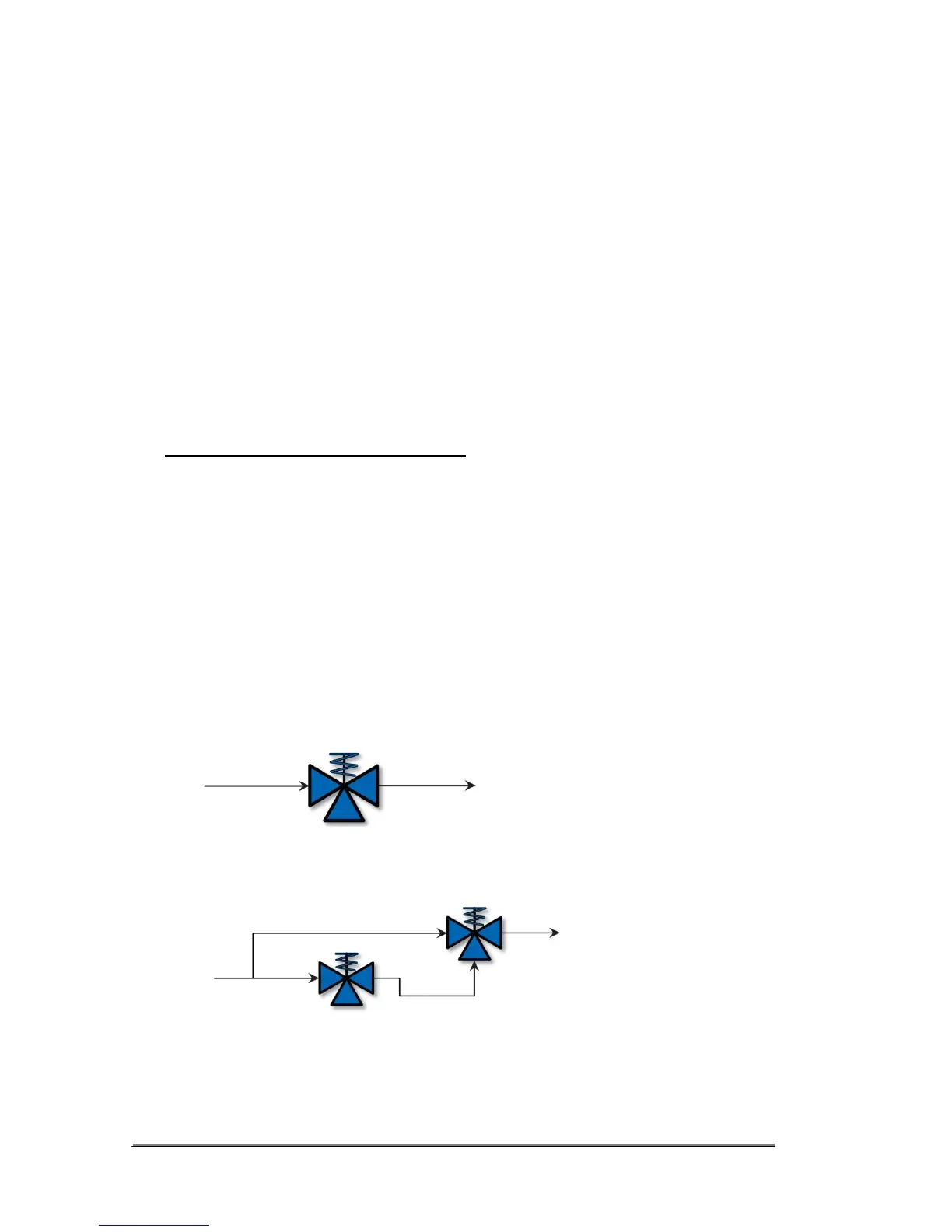

Typical 3-way pilot valve piping

configurations:

a. 1 out-of 1 – This is the most common pilot valve configuration

used.

b. 2 out-of 2 – This is commonly used for high availability applications. In the case that

one

solenoid valve was to spuriously trip, the second solenoid still maintains the position of

the

actuator/process valve at its operating state. Both solenoids must close in order to shift

the

actuator/process valve to its non-operating

state.

Loading...

Loading...