9

After having removed the machine from the packing material install it proceeding as follows:

1 Fill the tank with normal or better demineralized water up to 3 cm (1”) from the rim and close it with its cover.

The two hoses, coming from the pump filter, must be dipped into water down to the tank bottom.

As the machine is operated, the water pump will automatically start the water circulation. Should the water

circulation fail or be insufficient, the pressure switch placed on the water pump will not allow power output.

It is recommended to periodically check the flow of the circulating water, which must be 2 litres per minute

and it is measured at the machine water outlet by means of the special bottle included in the standard outfit.

2 Check the voltage of the mains. Any variation beyond 10% plus or minus than the voltage indicated by the

nameplate does not allow regular operation of the machine. Connect the line cord to the singlephase 230 V

mains with regular grounding. A possible automatic safety breaker must have a 0,5 A differential switch.

3 IMPORTANT: the machine is electrically controlled by an overload safety switch in compliance with the CE

regulations which cuts off power in case of current overloads due to faults in the machine or to current surges

of the mains.

This switch is located up on the left of the front side of the machine and it is indicated with A2 in the drawing

table A of the trouble shooting manual.

Should it cut off, unplug the machine, remove the front panel and set it again on the ON position. Fit the front

panel, switch on the machine and should the overload switch remain on the ON position it means the cutting

off was due to any occasional cause, should it cut off again it is necessary to ask for the technical service and

to look for the cause.

With the due precautions the machine can be switched ON by an authorized operator with the removed

panel .

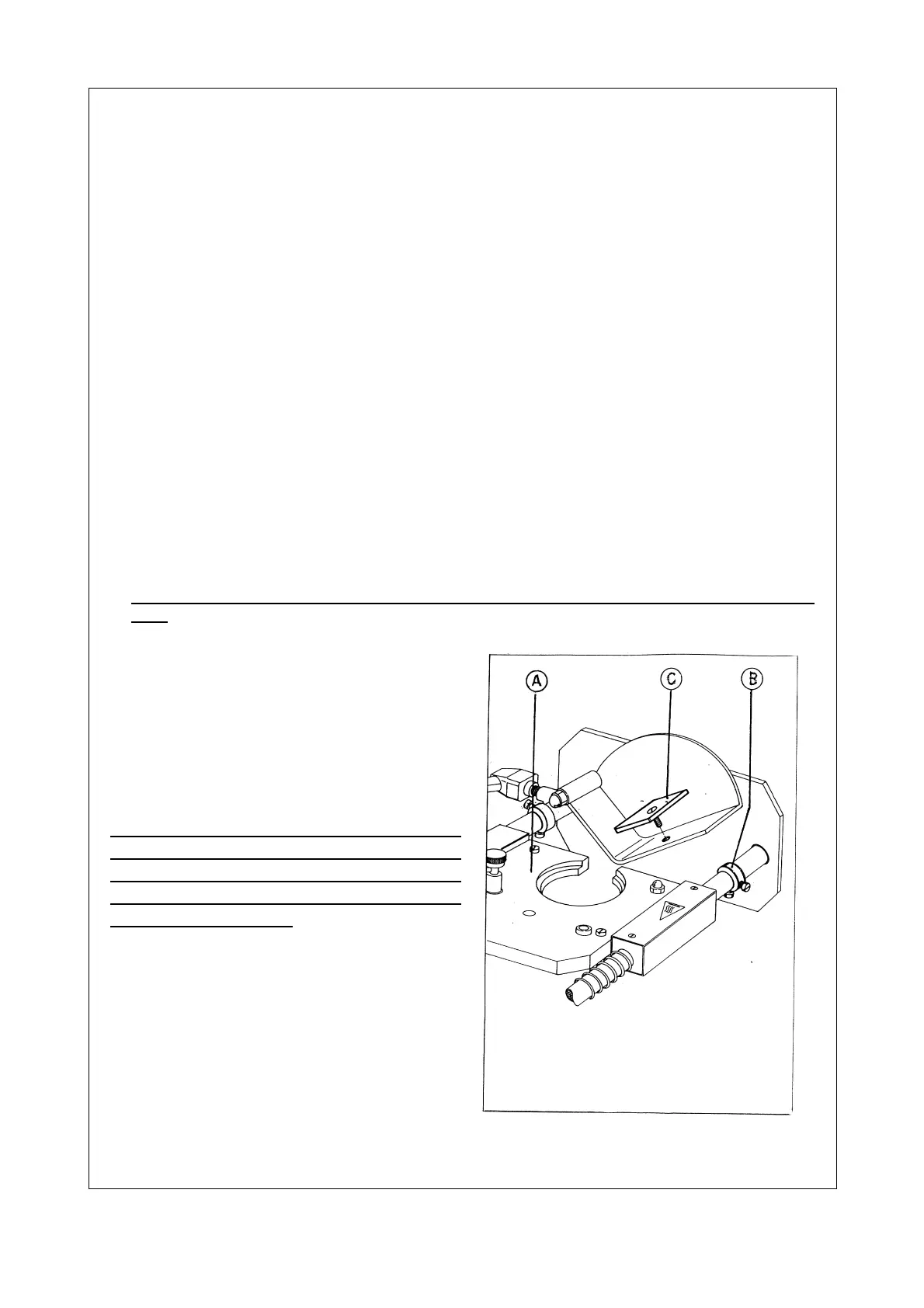

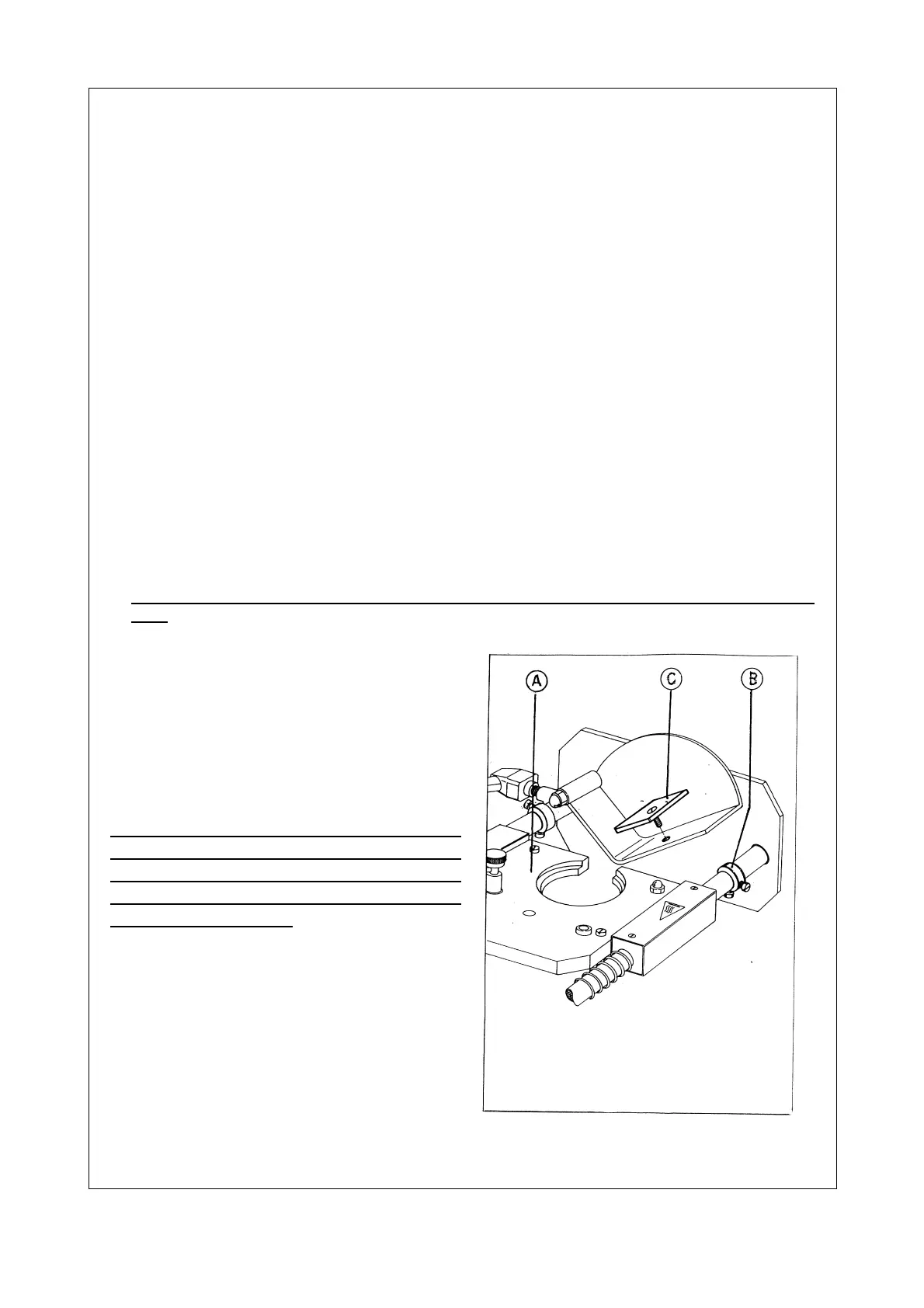

IMPORTANT NOTICE

For prevent the crucible holding plate A from breaking,

which slides against the flask when spinning is started,

place the ring B in such a way to stop the travel of the

crucible holding plate abt 2 mm from the flask.

The ring B must be positioned in relation to the

length of the flask. Do not place it too distant from

the flask otherwise the crucible exit nozzle will not

reach the sprue button of the flask and the metal

might spill during spinning.

When using small flasks with 48-50 mm ø the small plate

C is placed on the flask support to enable the sprue

button of the flask to be easily centered with the crucible

exit hole.

MODULAR 6

Loading...

Loading...