6

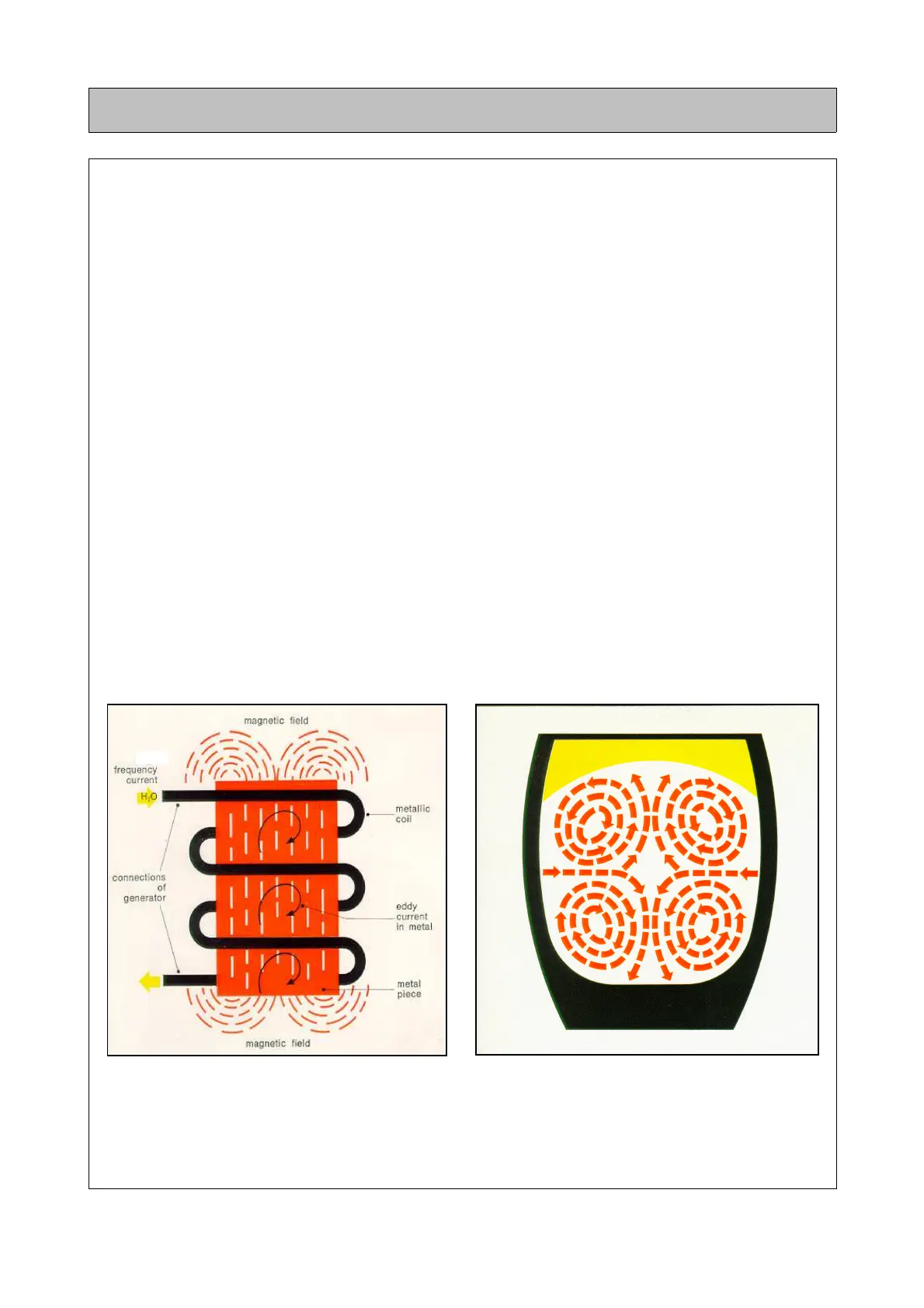

THE INDUCTION HEATING PRINCIPLE

The induction heating principle consists in placing a metal within the influence of an oscillating magnetic field at

a determined frequency such as the one generated by an induction coil. In the centrifugal casting machine mod.

MODULAR 6 the frequency is 80 KHz.

All metals have induced within them “eddy currents” and the metal electrical resistance to these

currents provokes a temperature rise and eventual melting.

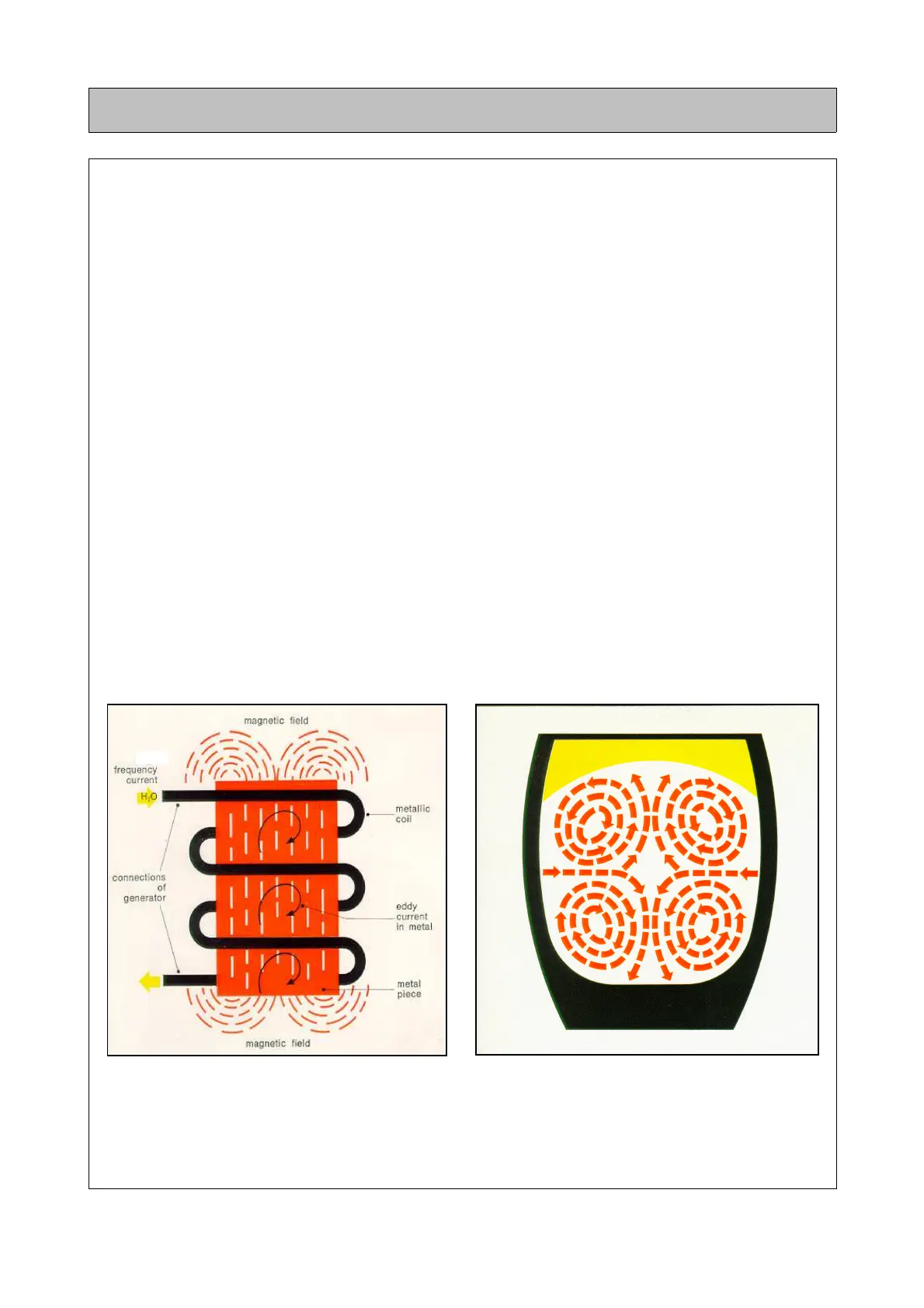

The “eddy currents” form a molecular movement in the melting metal and give a thermic homogeneity to the

melting mass as depicted by the pictures.

The induction heating results to be the best thermic energy source for melting and offers the following

advantages:

– unchanged metallurgical characteristics: elasticity, homogeneity, and ductility

– silent and clean working conditions

– higher purity of the molten metal

– great productivity

– high melting temperatures without jeopardizing the machine components

PICTURE 1

PICTURE 2

MODULAR 6

Loading...

Loading...