9

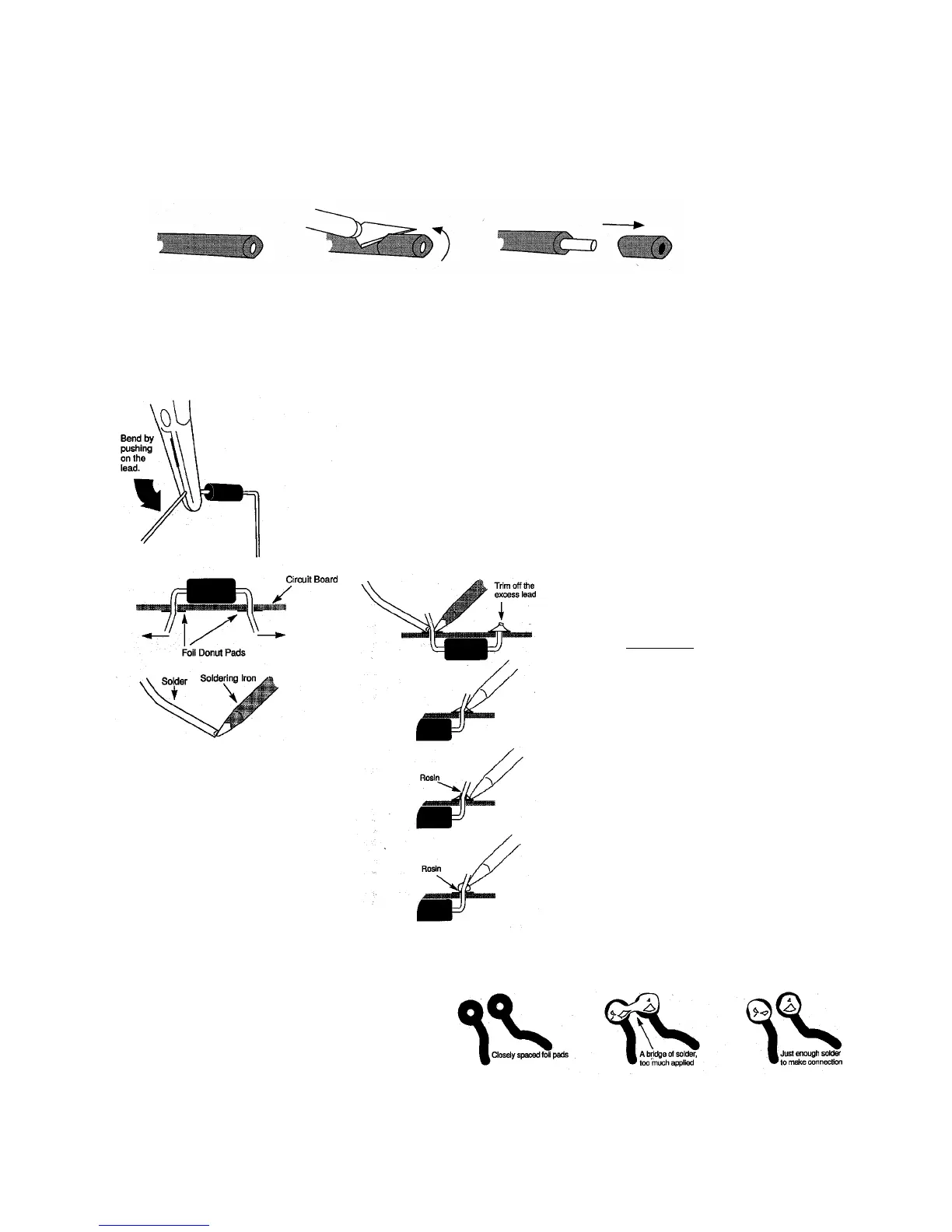

Wire Stripping with a Knife

If you own a wire stripper, we’re assuming you know how to use

it. If not, and you are new to the world of audio construction, you

can use a hobby knife to do the same job. Simply cut around the

insulation leaving an appropriate length for the lead, be very

careful to cut only the insulator and not the wire itself. Pull the

excess insulation away and you have your lead. If the wire is

made of strands, twist the lead between your fingertips to keep

it from fraying.

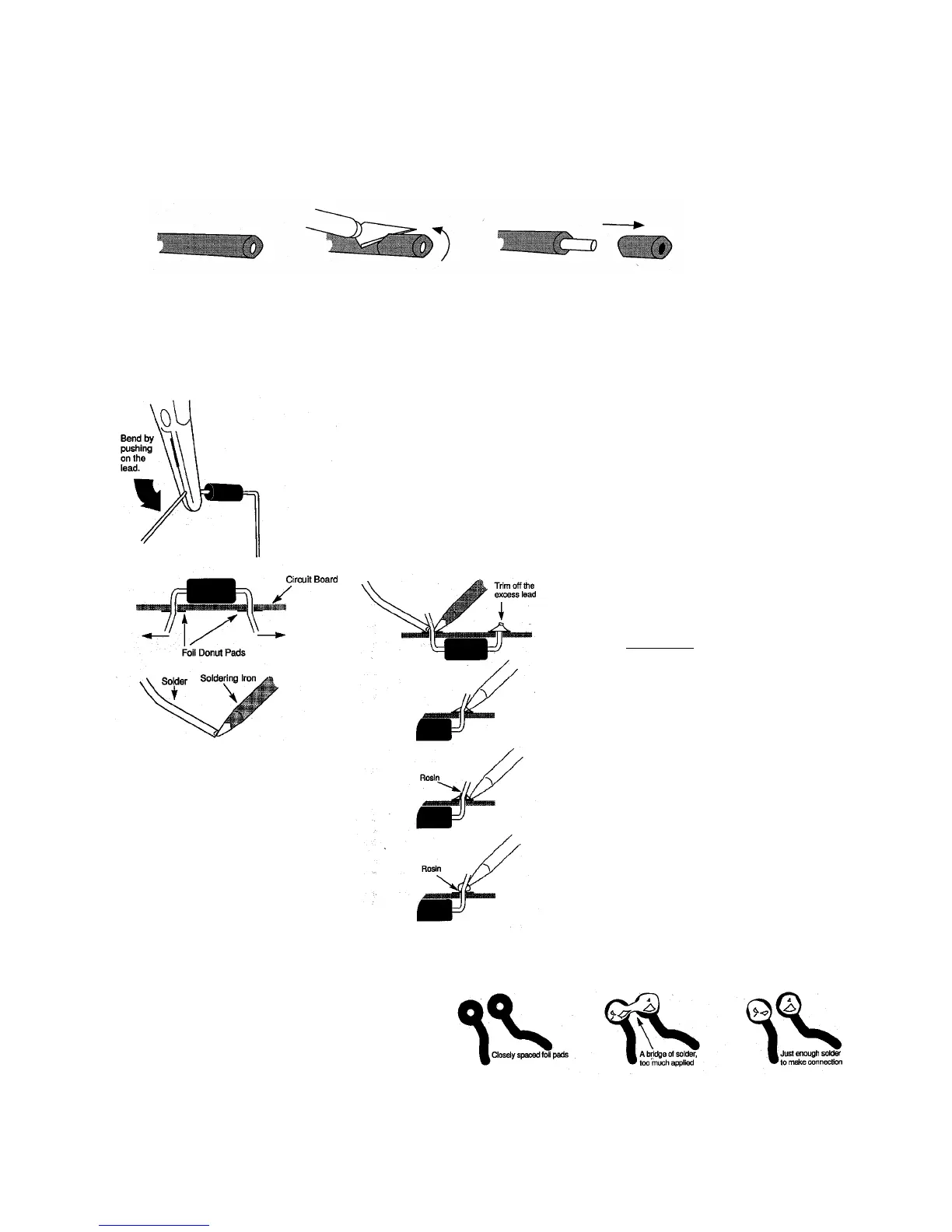

• If a lead bender is not being used, hold the component (resistor,

capacitor, LED,...) with a pair of needle nose pliers and bend the

leads to the appropriate width so it can fit through the donut

pads in its position on the circuit board.

• DO NOT bend the leads by applying pressure to the component,

bend by pushing directly on the lead. Bend only as in the picture,

this will make it easier to remove the parts from the PCB in the

event that you may want to upgrade the part later, without

removing the PCB from the chassis.

• Position the component on the circuit board and hold it in

position as you bend the leads out.

• To help conduct the heat from the soldering iron, “tin” the tip of

iron by applying a touch of solder to the already heated iron tip.

Soldering

• Push the soldering iron tip against the lead and the foil

donut pad on the circuit board and hold for 2 seconds.

• Then apply the solder to the other side of lead, also

touching the donut pad. Let the heated lead and pad melt

the solder,

not the iron tip. The solder should flow aro u n d

the lead.

• Remove the iron and solder and let the connection cool.

Trim off the excess lead.

• NOTE: When done C O R R E C T LY, by heating the lead and

foil donut pad simultaneously, the solder should flow

o u t w a rd, gradually blending from the lead to the foil.

• When done I NC O R R E C T LY, by just heating the foil pad

and not the lead, a hard rosin bead will surround the lead,

insulating it from the connection.

• An I NC O R R E C T solder joint is also done by just heating

the lead and not the foil pad. Here a hard rosin bead form s

on the pad, insulating it from the lead.

• To correct these unacceptable solder joints reheat and if

n e c e s s a ry apply a little more solder.

• H I N T: It is handy to keep a damp sponge nearby to clean

the iro n ’s tip after each joint is completed.

Solder Bridges - solder bridges usually happen when too much

solder is used, or the solder is dragged from one connection to

another when heat is applied. If a bridge develops, turn the

circuit board upside down and reheat the connection, allowing

the solder to flow onto the iron tip. Then resolder the connections

as before, being careful that just enough solder is used to make a

c o n n e c t i o n .

Loading...

Loading...