13

* The socket conn

ections have to be made by a qualified electrician,

the rotation direction of the saw blade has to b

the machine. If the saw blade rotates in reverse direction, the socket

connections have to be checked and re-connected properly.

** I

f the direction of rotation of the saw blade is reverse, it is dangerous

for the operator and equipment. It causes the saw blade

and crack.

Saw Blade Rotation Direction

Connect the saw in accordance with the wiring scheme provided with the saw. Make sure that the saw blade

rotates in the correct direction. Follow the following procedure:

1. Press the motor start button to rotate the saw blade

2. Observe the direction of rotation of the saw blade.

3. The direction of rotation of the saw blade is indicated with an arrow on te machine table.

If, as a result of this application, you see that the saw blade rotates in reverse direction:

Electrical connection has to be corrected by a licensed electrician (usually switching 2 hot wires).

The direction of rotation of the saw blade should not be defined without testing.

5.3. AIR PRESSURE ADJUSTMENT

5.3.1. Pull up the air conditioner adjustment knob.

a. The pressure increases when the setting button is turned clockwise.

b. The pressure decreases when the setting button is turned counterclockwise.

5.3.2. When you read the 6-8 bar pressure setting on the pressure gauge, lock the conditioner setting knob by

pushing it downwards.

5.3.3. Manufacturer recommended lubricant for conditioner: TELLLUS C 10, BP ENERGOL HLP 10, MOBILE DTE

LIGHT.

6. MACHINE SAFETY INFORMATION

6.1.1. It is forbidden to work by removing protective security equipment such as protective safety

covers and such.

6.1.2. Your machine must be operated with the voltage on the technical label. Make electrical

installation of your machine with a licensed electrician.

6.1.3. Qualified and competent personnel should be used for lifting, placing, electrical and

pneumatic maintenance work.

6.1.4. Routine maintenance work and scheduled maintenance must be carried out by authorized and qualified

personnel after the electrical and pneumatic power supplies are deactivated.

6.1.5. Before starting to work on the machine, make sure that the machine has been cleaned, tested and

maintained.

6.1.6. Routinely check the safety equipment, electrical power cable and moving parts. Do not operate the machine

don't starting it with a new one if you experience damage that can not fulfill safety functions or parts functions.

6.1.7. Never change the circle saw without interrupting the electrical power connection.

6.1.8. Do not place foreign objects in the operation area, do not place your hands between moving parts.

The safety informations is defined above. To prevent physical damage or equipment damage, please read

the safety information carefully and always keep the information in mind.

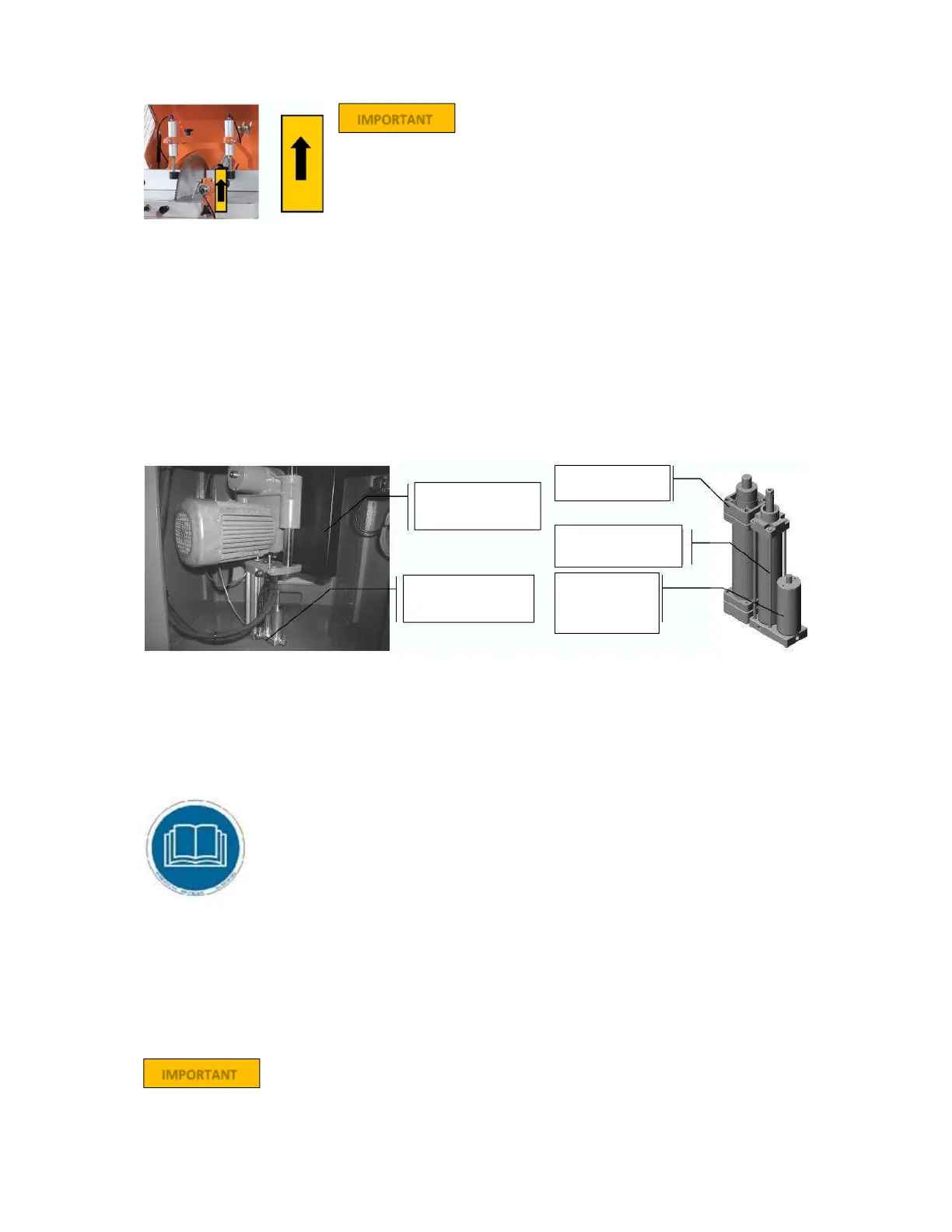

Saw Blade

Housing Guard

Hydro-Pneumatic

System Group

Cylinder

Hydraulic

Cylinder

Hydro-

Pneumatic

Tank Cylinder

Loading...

Loading...