17

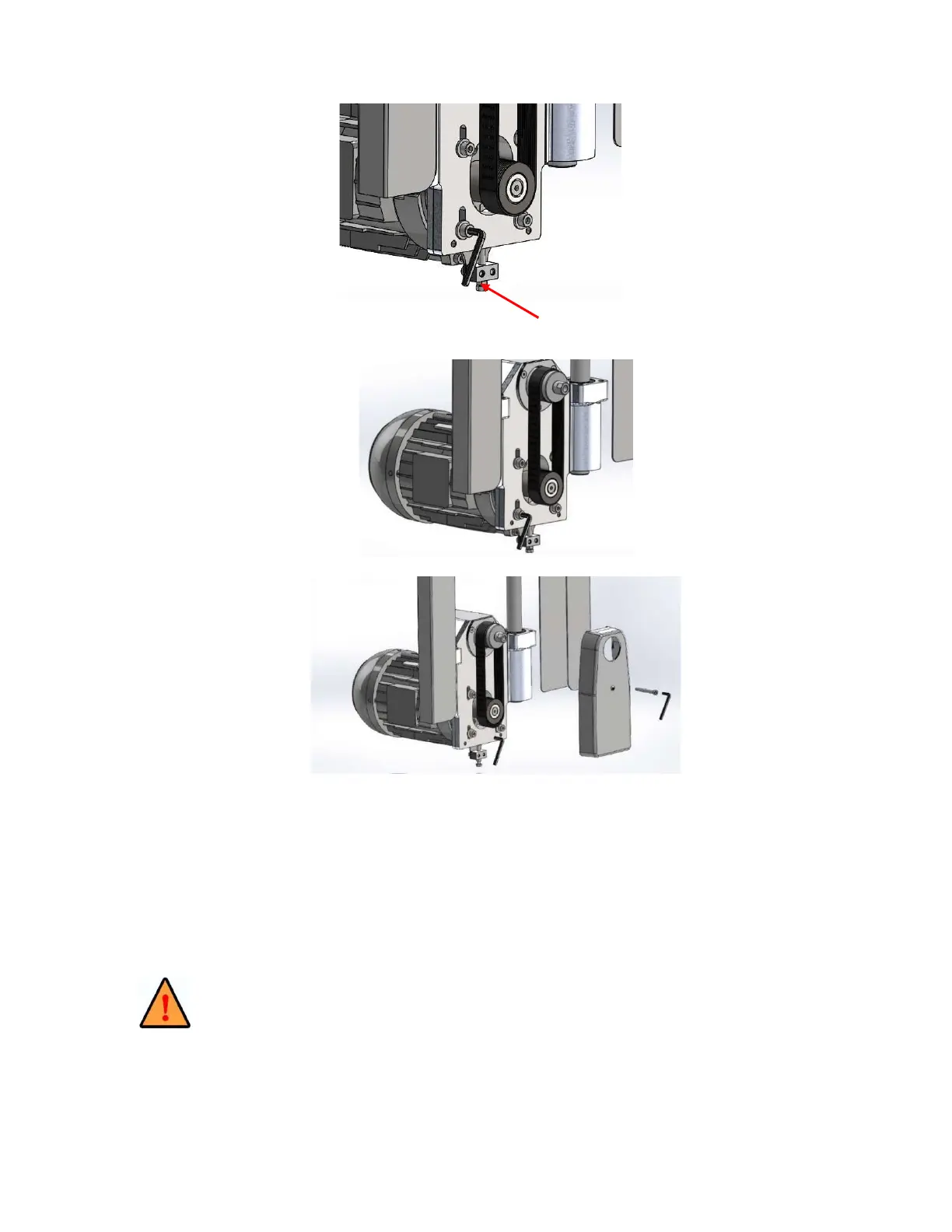

9.1.5. Loosen the M8 screws by turning them clockwise with a 6 mm Allen key.

9.1.6. You can change the belt by loosening the motor block.

9.1.7. Once you have changed the belt, finish the process by following the procedures.

10. MAINTENANCE

10.1. ROUTINE CONTROLS, MAINTENANCE AND WORK STARTING

10.1.1. Make sure the table and all parts are clean and dry. Clean the table from the oil and dry it. Be especially

sure of the cleanliness and dryness of the handle.

10.1.2. Clean all surfaces of the machine from the sawdust, chips and foreign materials. Use glasses and glove to

protect yourself from harmful substances.

10.1.3. Check the saw blade against wear, bending, cracking and breakage before each use. Turn carefully to see

each tooth of the saw (after removing the saw protective housing). If the saw is damaged, change the saw.

10.1.4. Check the air pressure system pressure. If necessary, set the air pressure around 6-8 bar

10.1.5. Check the air pressure filters and the oil level in the conditioner. If you do not have enough oil, complete it.

Disconnect the electrical power connection and air pressure connections before doing all this.

10.2. METHOD OF HYDRO-PNEUMATIC CYLINDER AIR DISCHARGE AND ADDING OIL

10.2.1. METHOD OF HYDRO-PNEUMATIC CYLINDER AIR DISCHARGE

1. Revmove the 4 inbus head bolts, which connect the hydro-pneumatic cylinder to the system.

2. Remove the countersunk bolt which is connected to the saw bore of the shaft, from the top side of the

bore.

Loosen with 10 mm key

Loading...

Loading...