18

3. Remove the bolt, which connects the rising speed setting unit, located left from the control panel, to the

saw body..

4. Ake out the hydro-pneumatic cylinder.

5. Pull it out so that the shaft inside the hydro-pneumatic cylinder is in OPEN position (out position)

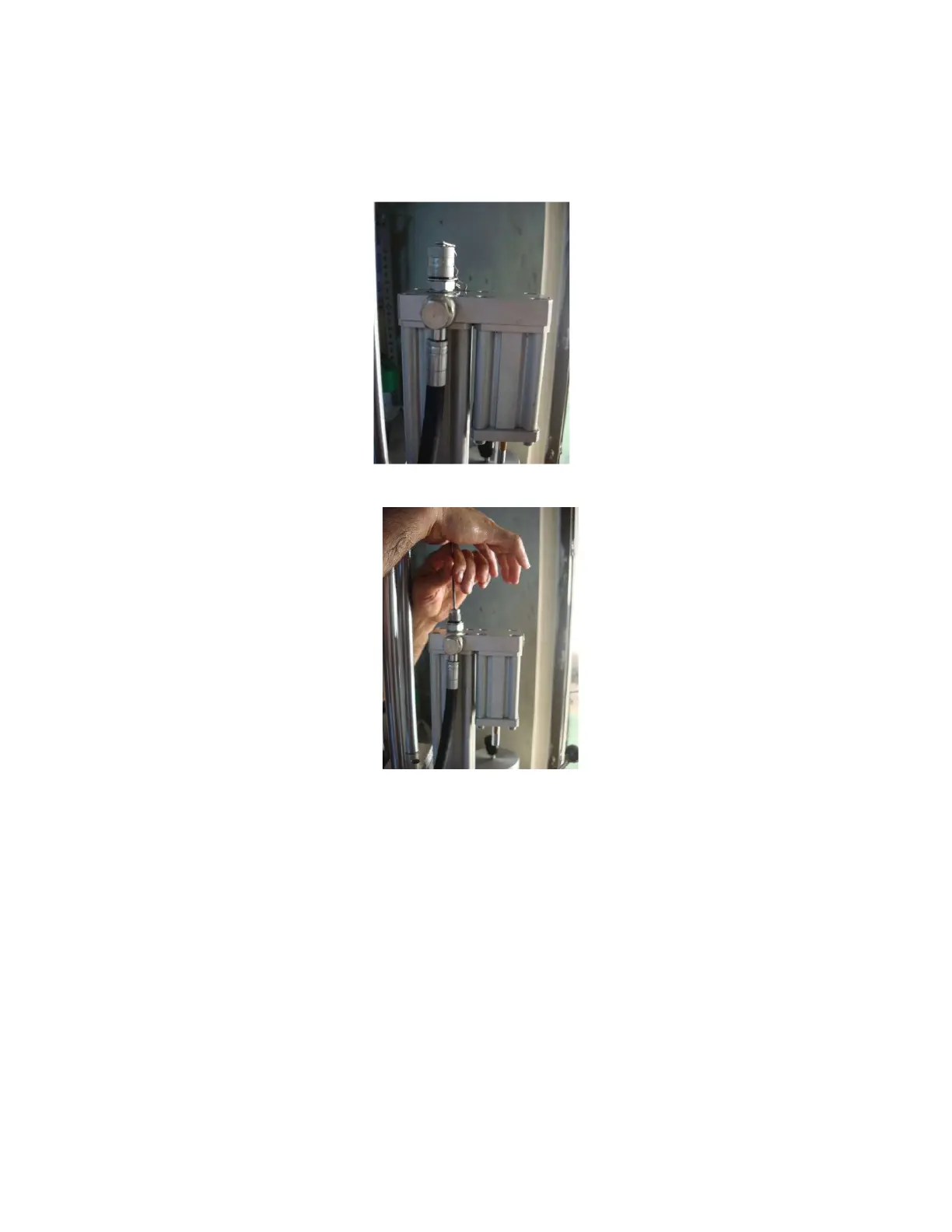

6. Connect/tighten the unit in the position as shown in the picture to the clamp.

7.

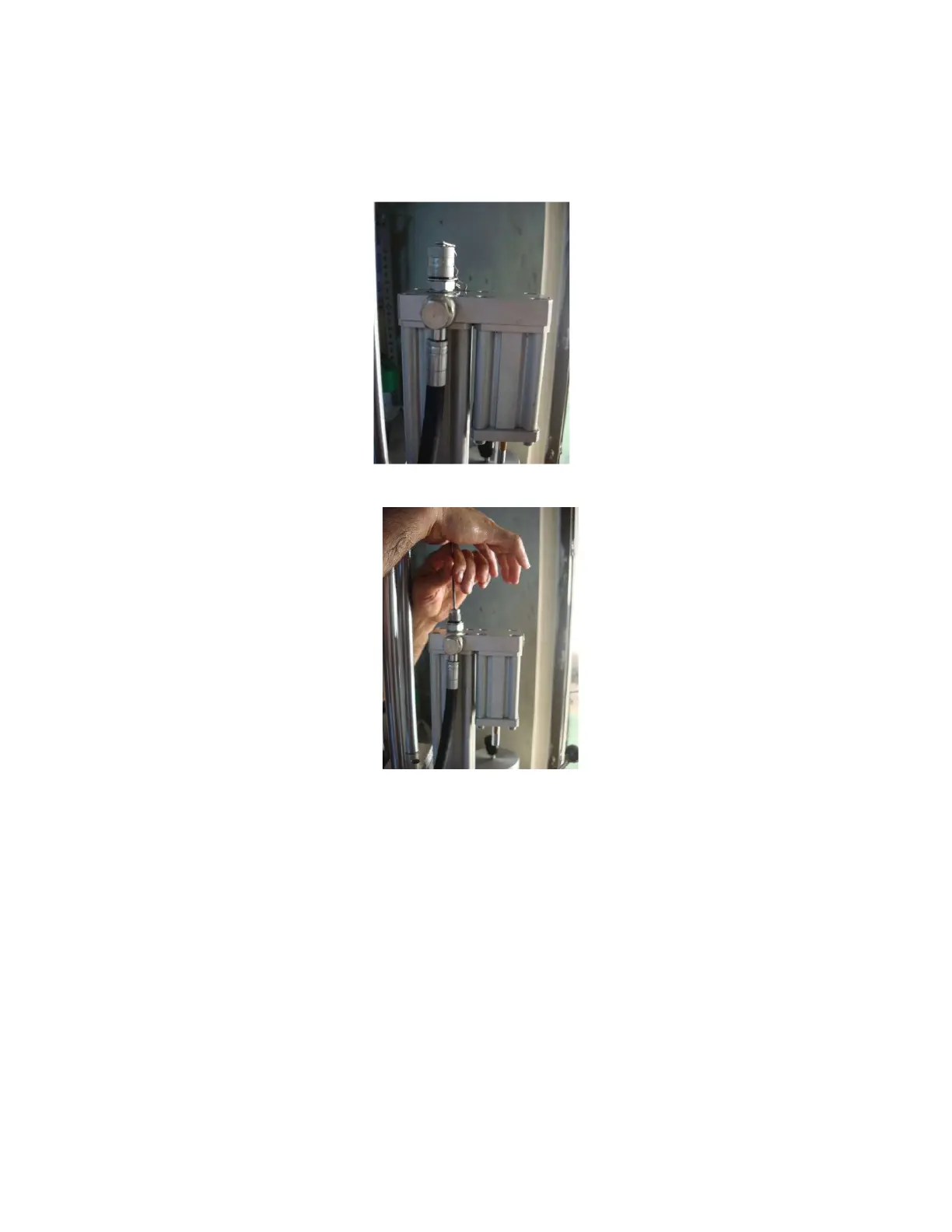

Open the oil drain / air discharge unit plug in the shape of the photo.

8. Press gently on the top of the oil discharge unit with a flat, blunt metal (for example 3 mm allen).

a. Foamy oil will come in the first place during pressing.

b. Continue this process slowly until the unfoamed oil comes out.

9. When the oil is foam free stop the process and wipe with a dry cloth. Replace hydro-pneumatic cylinder.

.2.2. OIL ADDING METHOD

It is possible that necessary oil level is reduced after the air discharge process. Since the amount of oil in the

system is reduced, the rising distance of the saw blade can be reduced. Here's what you need to do to get your saw

blade to reach the maximum height again. You need an oil pump for adding oil. However, if you do not have an oil

pump you can also do the following.

1. Follow the same steps until the first 6 items of hydro-pneumatic air discharge.

2. Remove the oil filler unit.

3. Add "HYDRO OIL HD 46" or equivalent oil to the system and close the oil filling unit.

4. Repeat steps 7 and 8 of the hydro-pneumatic cylinder air discharge method to discharge any possible air in the

system.

Loading...

Loading...