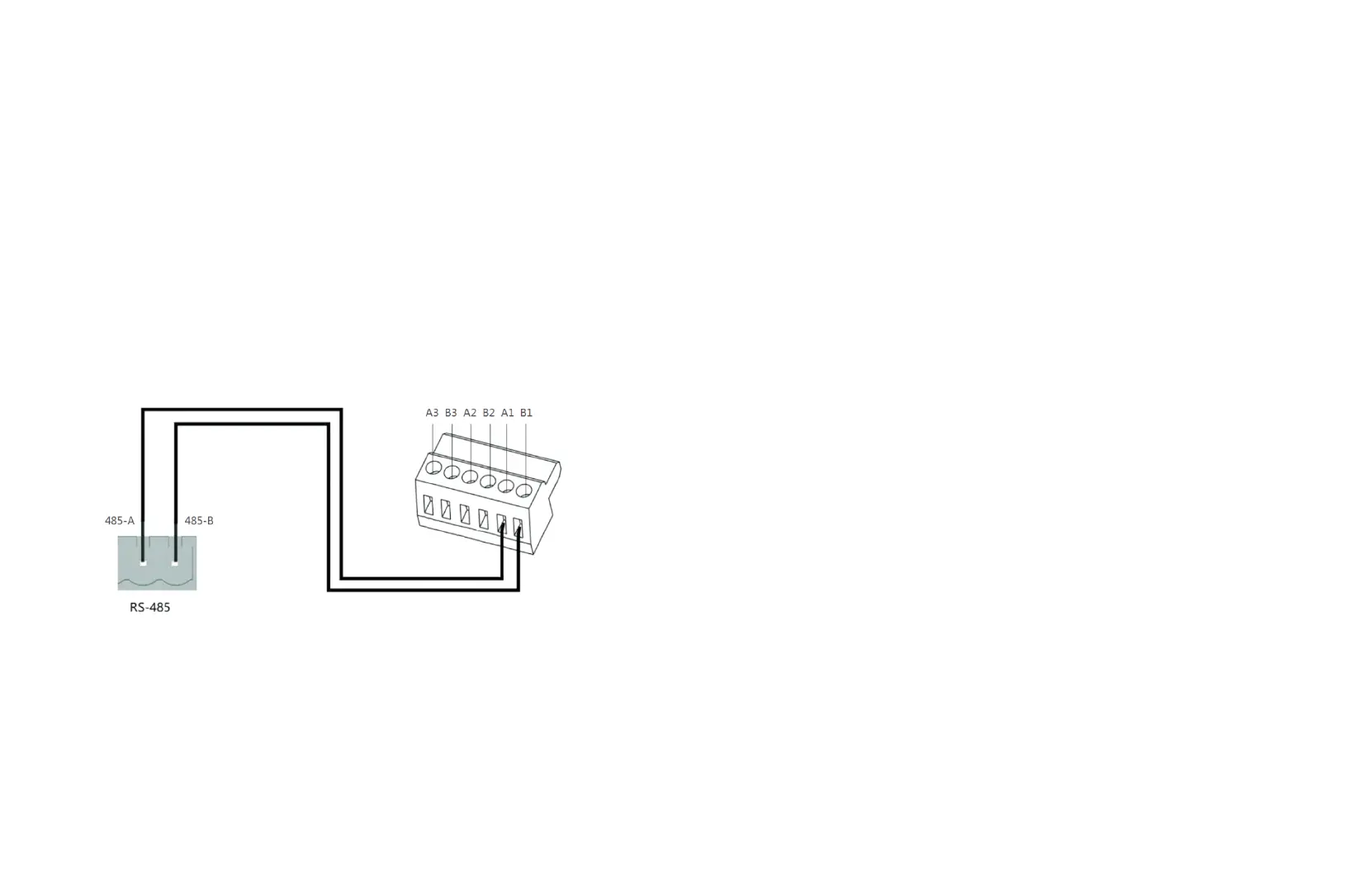

3.3.1 RS485 cable connection

3.3 Connect with device

EnerLog can communicate with energy storage inverters, BMS and other equipment to

achieve the purpose of data collection.

1.EnerLog (master) and device (slave) communicate through RS485 wired

connection. The 485-A on the RS485 port of the device corresponds to A1, A2 or A3 on

the EnerLog 485 port, and the 485-B on the RS485 port corresponds to Corresponding

to B1, B2 or B3 on the EnerLog 485 port. The following is a schematic diagram of the

connection between EnerLog and the inverter:

8

9

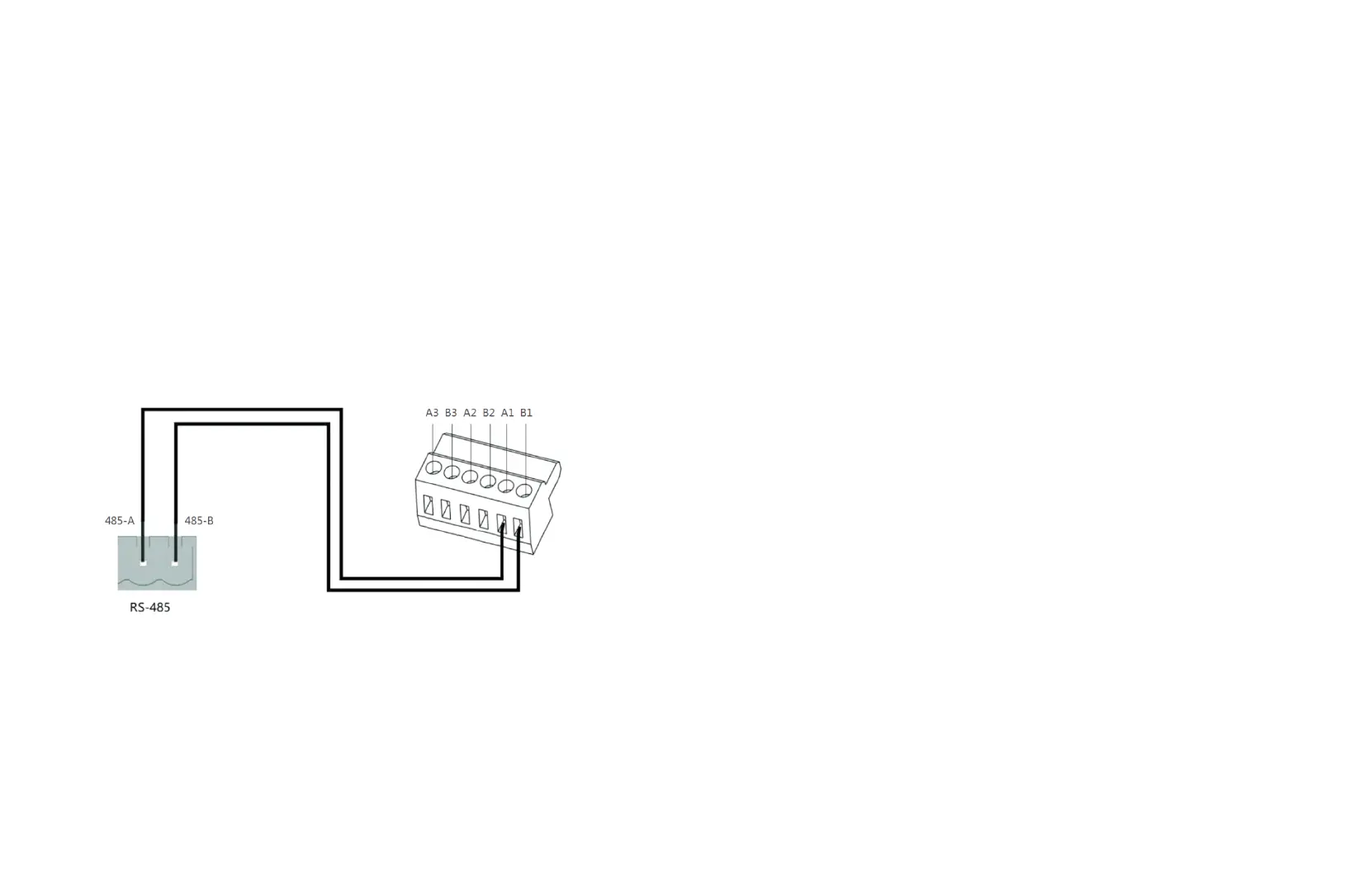

2.The inverter and the inverter are connected to the EnerLog through the RS485 line

parallel connection, and the RS485 wired communication connection is adopted. The

EnerLog can stably monitor up to 30 devices (each RS485 channel connects 10

devices).

The functions of the A1B1, A2B2, and A3B3 channels are the same.

3.Other 485 communication equipment such as: BMS, combiner box, etc., the

connection method is the same as that of the inverter.

4. Notice:

(1) RS485 shielded wire must be grounded (PE) during communication to avoid

affecting the stability of communication.

(2) The three 485 channels provided by EnerLog are all connected with 120 ohm

matching resistance, so when one or more inverters communicate with EnerLog for

485, one inverter must be connected with 120 ohm matching resistance to avoid

affecting communication (In a 485 channel, only one of multiple inverters can be

connected to matching resistance, and multiple inverters cannot be connected to

matching resistance at the same time), it is recommended that the most remote

inverter is connected to matching resistance.

(3) Environmental detectors, combiner boxes and other equipment must be

manufacturers designated by ATESS, otherwise monitoring cannot be achieved.

Loading...

Loading...