Preparations before starting

Check the drilling equipment

♦

Check that all of the drilling equipment is in good

condition.

♦

Check that the impact surface of the drill steel

shank is flat, with no signs of wear.

♦

Make sure that the air inlet and exhaust ports are

free from obstructions.

♦

Check that the flushing holes in the drill steel and

drill bit are not blocked, and that the flushing air

and water flows through without obstruction.

♦

Make sure that the air filter (located in the air

nipple) is clean and not torn or distorted.

♦

Ensure that the fittings are tight and leak-proof.

DANGER Whipping air hose

A compressed air hose that comes loose can lash

around and cause personal injury or death

► Check that the compressed air hose and the

connections are not damaged.

► Check that all compressed air connections are

properly attached.

Blow out the air hose

♦

Every day before using the drill, blow out the air

hose to clear it of accumulated dirt and moisture.

Fill the lubricator with oil

♦

Check that the chuck and insertion tool shank are

always covered with a film of oil.

Attaching the pusher leg to the rock drill

The pusher leg must be fixed to the rock drill by

means of the bayonet coupling.

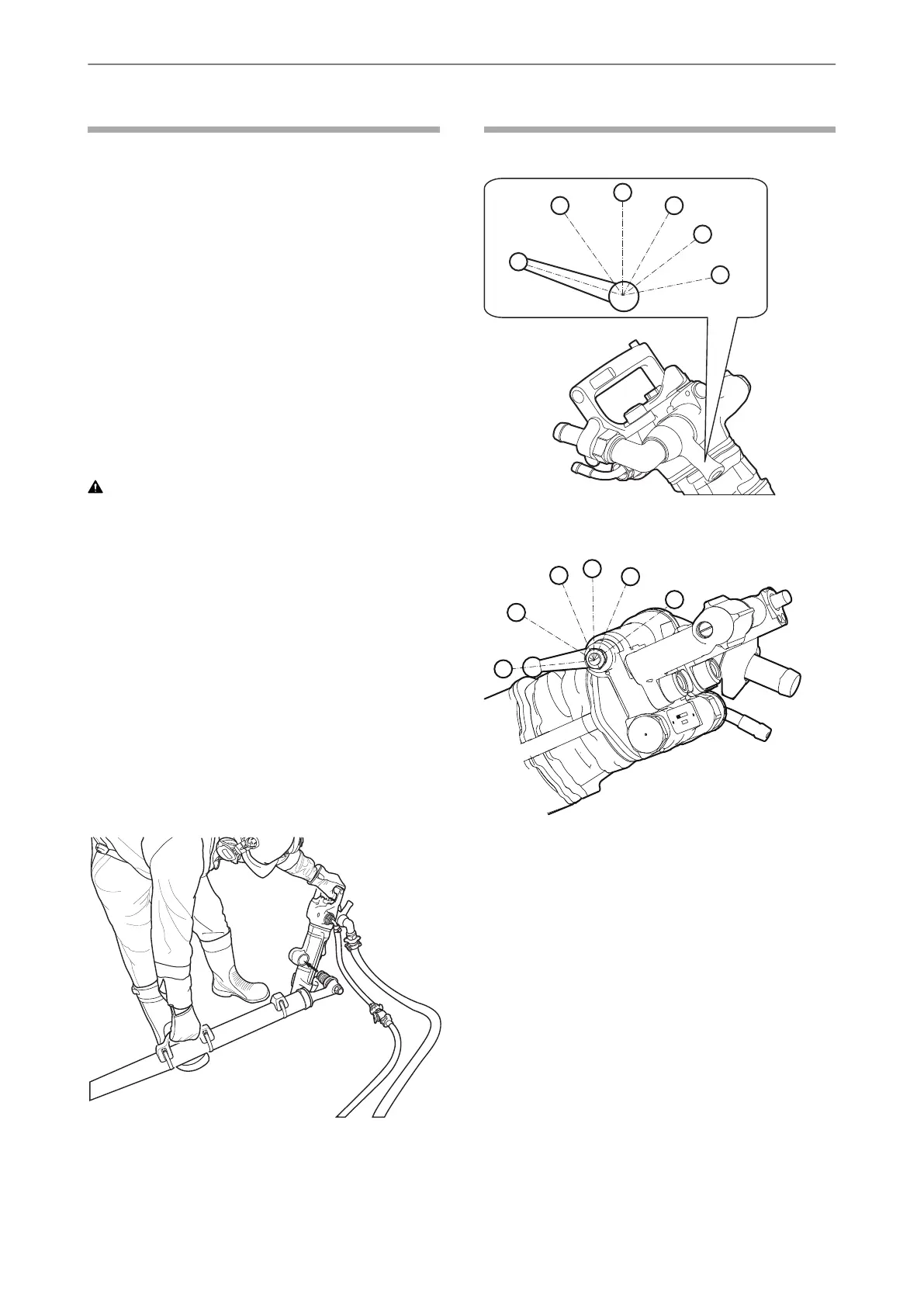

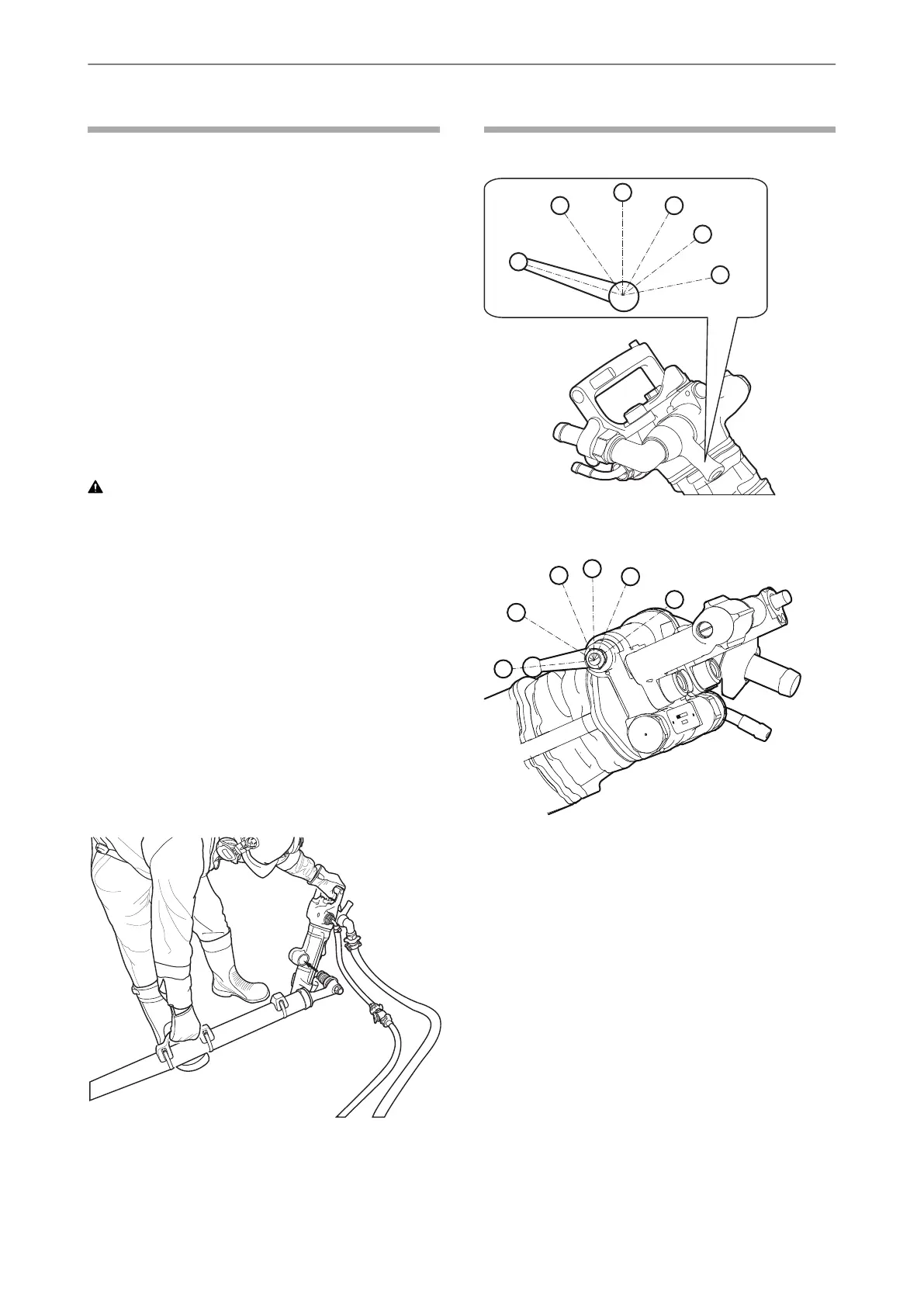

Controls

Throttle lever

BBC 16W/WS, BBC 34W/WS

BBC 34WTH

The rock drill is equipped with a throttle lever for

regulating both the compressed air to the percussion

mechanism and the flushing water.

A. Throttle valve closed (stop position).

Blow-cleaning only.

B. Air to pusher leg.

C. Flushing water.

D. Air to percussion mechanism.

E. Throttle lever fully open (full throttle).

F. Extra blowing.

© 2012 Atlas Copco Construction Tools AB | No. 9800 0627 71f | 2012-06-30

Original instructions

18

BBC 16W, 16WS, 34W, 34WS, 34WTHSafety and operating instructions

Loading...

Loading...