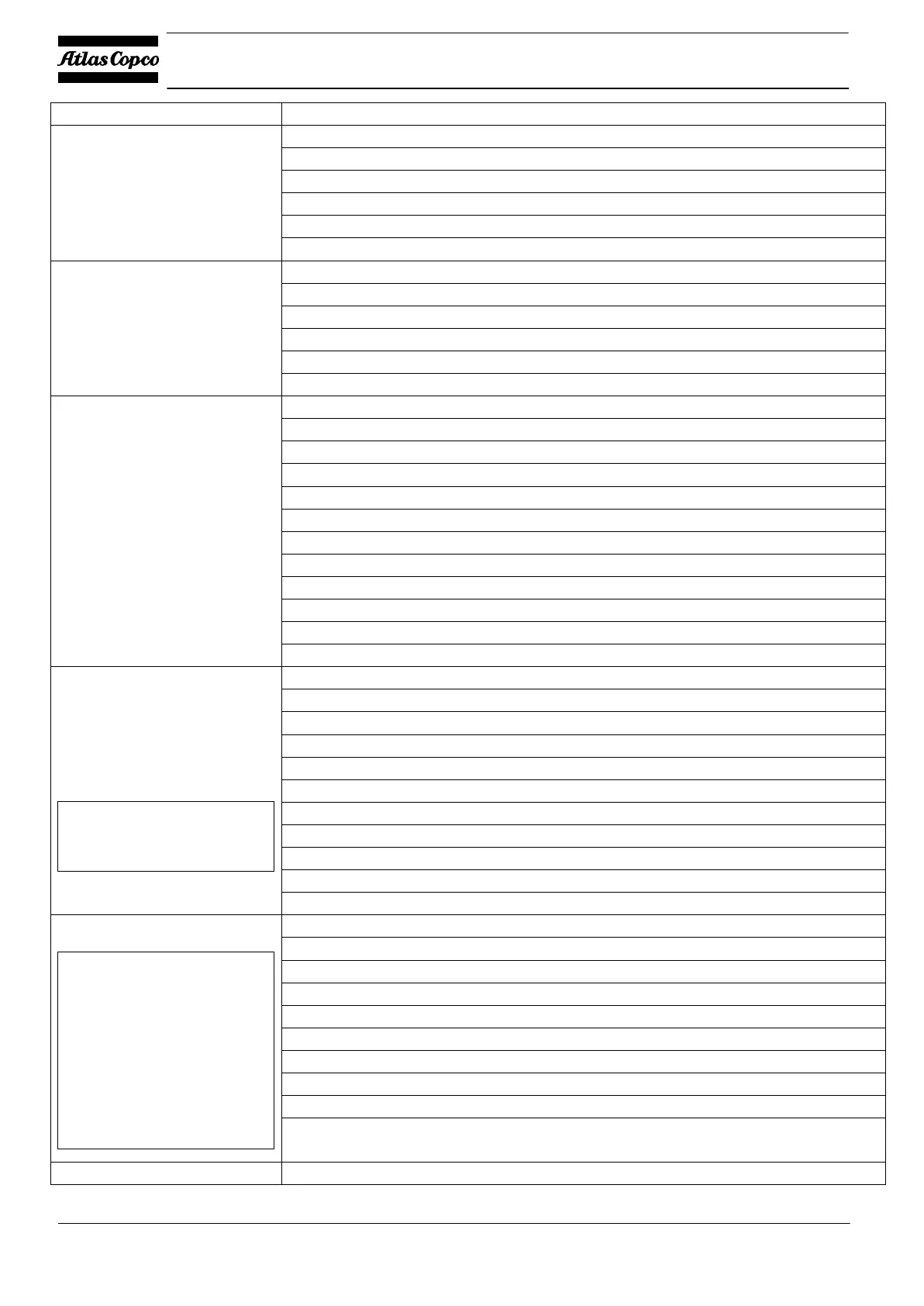

46 2022 2096 26

High discharge temperature

Compressor valve assemblies defective

Discharge pressure too high

Inadequate ventilation or hot air recirculating

Cooling surfaces of compressor or intercooler excessively dirty

Ambient temperature too high

Scored or excessively worn cylinder walls

Head clearance insufficient

Piston loose in cylinder bore, cylinder bore worn, piston or piston rings worn

Worn rods or main bearing

Wrong pressure setting, discharge pressure excessive

Crankcase lubrication inadequate

Excessive oil consumption

Compressor runs unloaded too long

Compressor running too hot

Breather valve not functioning properly

Oil level in crankcase too high

Oil viscosity wrong for the application

Connecting rod out of alignment, bent or twisted

Piston rings not seated (allow 100 hours for seating)

Wrong oil (may be a detergent oil with a tendency to foam)

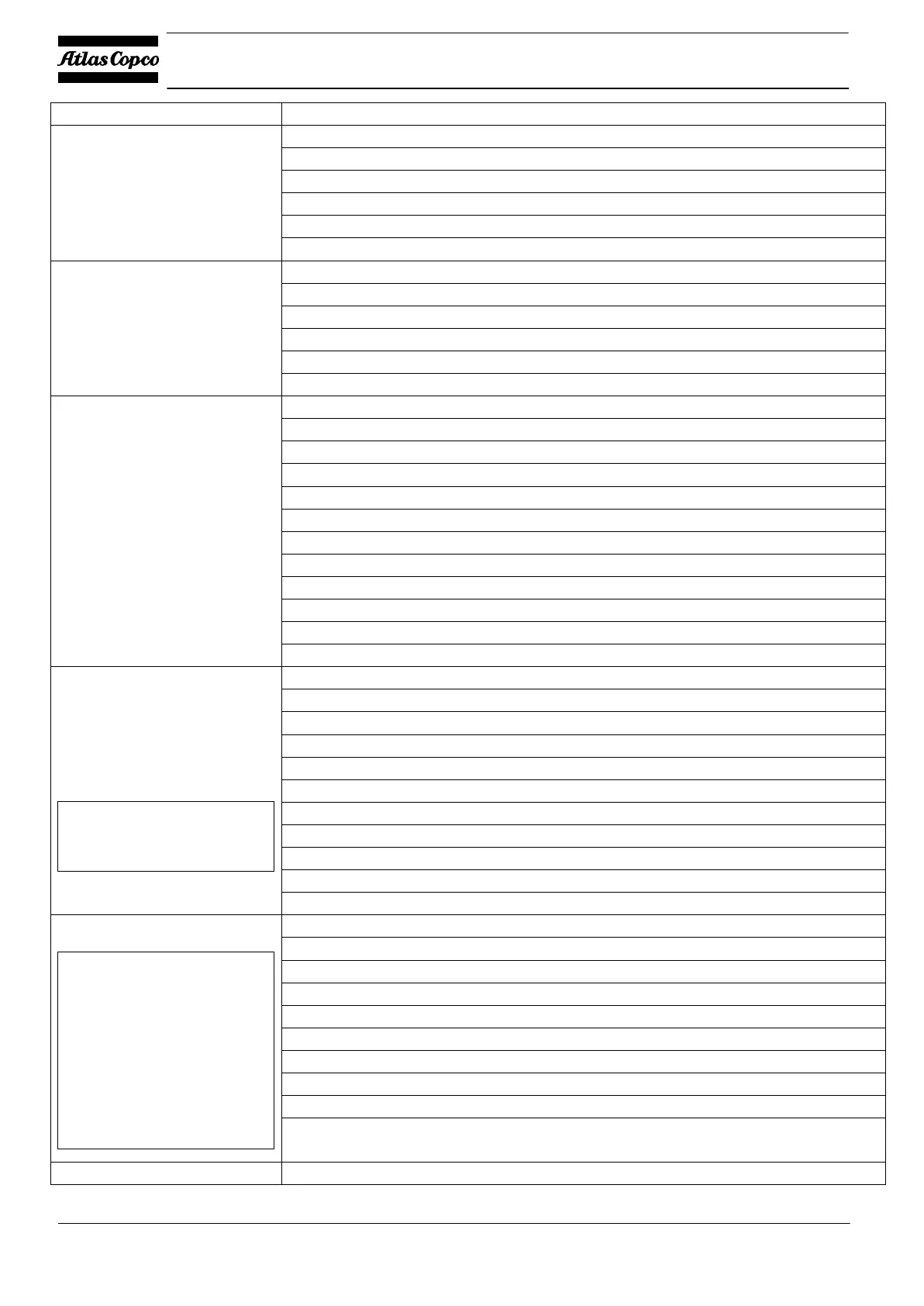

(To determine maximum

amperage allowed, multiply

the FLA on the motor

nameplate by the service

factor.)

Motor surface temperature

normally exceeds 170° F.

Low voltage (must be within 10% of nameplate voltage)

Loose electrical connection

Discharge pressure too high

Bearings tight or seizing

Overload relays are

designed to protect the

motor from damage due to

motor overload. If the

overload relay trips

persistently, DO NOT

CONTINUE TO PUSH THE

RESET BUTTON! Contact

your local Quincy

distributor for assistance.

Pressure switch incorrectly adjusted or faulty

Loading...

Loading...