- 35 -

Notes

1. More frequently when operating in a

dusty environment.

2. Replace the element when the pressure

drop exceeds 0.8 bar (11.6 psi).

3. Every 1500 hours. Refer to the Deutz

operation manual.

4. 500 hours is only valid when using

PARO IL 1 5W4 0.

5. In case of poor fuel quality, replace fuel

filter more frequently.

6. Clean retainer when replacing element.

7.

The following part numbers can be

ordered from Atlas Copco to check

on inhibitors and freezing point:

2913 0028 00 refractometer

2913 0029 00 pH meter.

Keep the bolts of the housing, the lifting

beam, tow bar and axles securely

tightened. For torque values see section

Technical specifications.

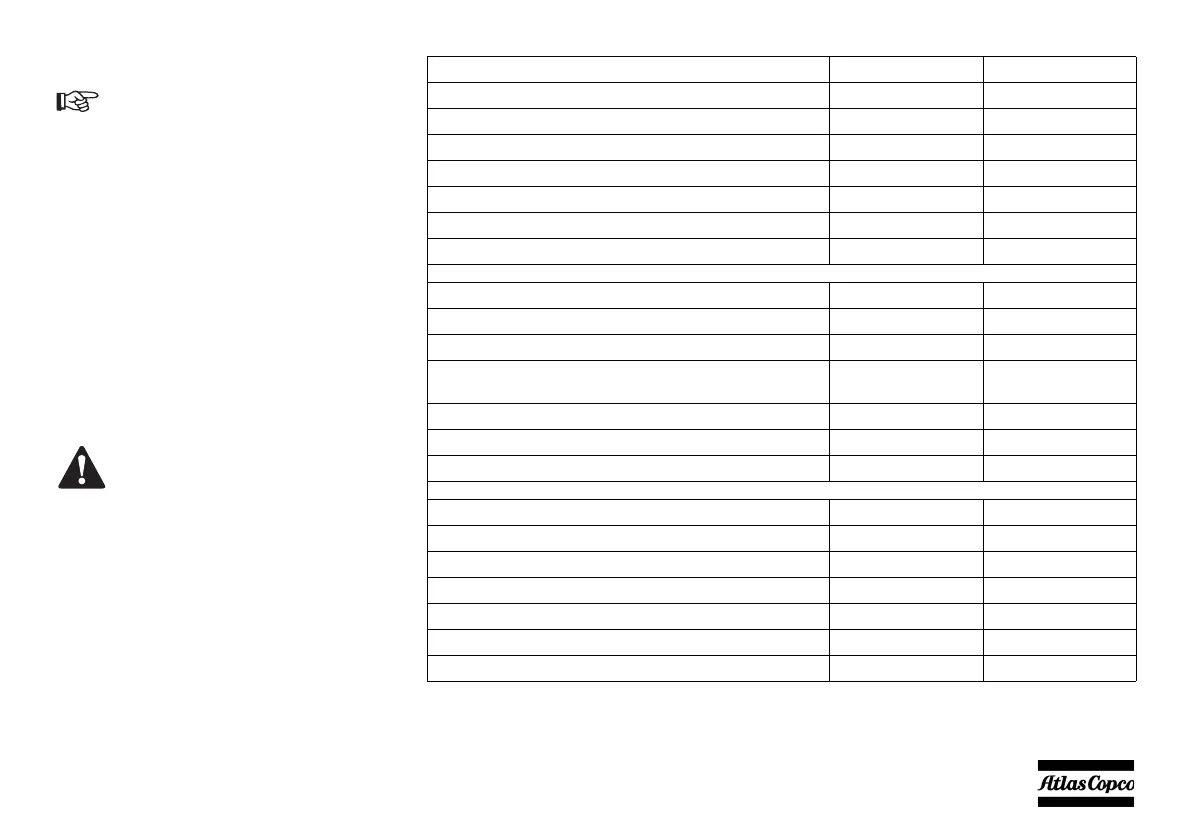

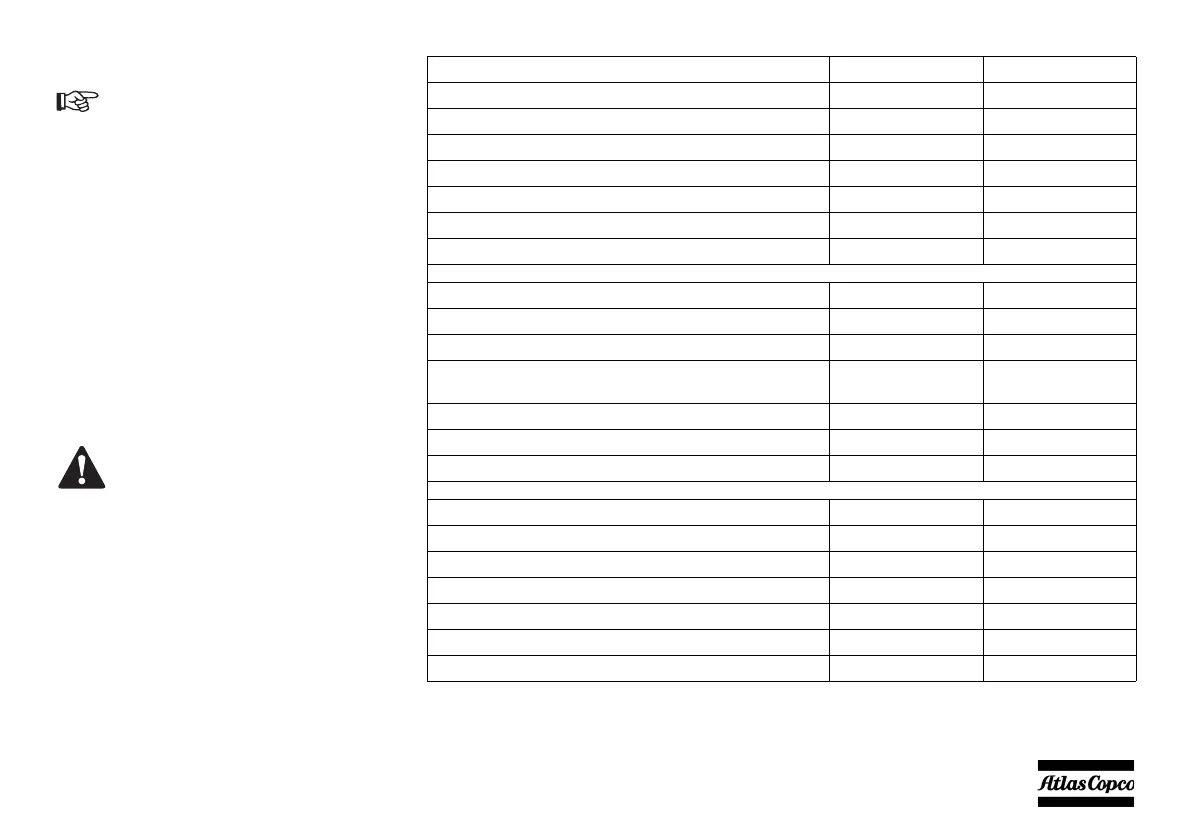

Maintenance schedule Initially Interval

Wheels

Tyre pressure Before each run

Check wheel bolts for firm seating Before first run

Check hub caps for firm seating 2,500km/annually

Check tyres for uneven wear 2,500km/annually

Check lateral play of bearings After 500 km 2,500km/annually

Check brake lining wear 5,000km/annually

Towbar

Check coupling head for wear, operation and fastening Before first run 5,000km/annually

Check brake play After first run 2,500km/annually

Check height adjustment facility Before each run,

during first 500 km

5,000km/annually

Check reversing lever for ease of motion 2,500 km 5,000km/annually

Check safety cable and bowden cable for damage 5,000km/annually

Check/ adjust brake system (if installed) Before first run 2,500km/annually

Lubrication

Coupling head and all its moving parts/shaft Before first run 2,500km/annually

Overrun brake Before first run 5,000km/annually

Reversing lever Before first run 5,000km/annually

Overrun coupling Before first run 5,000km/annually

Joints of height adjustable towbar 5,000km/annually

Bearings (conventional bearings only) 5,000km/annually

Loading...

Loading...