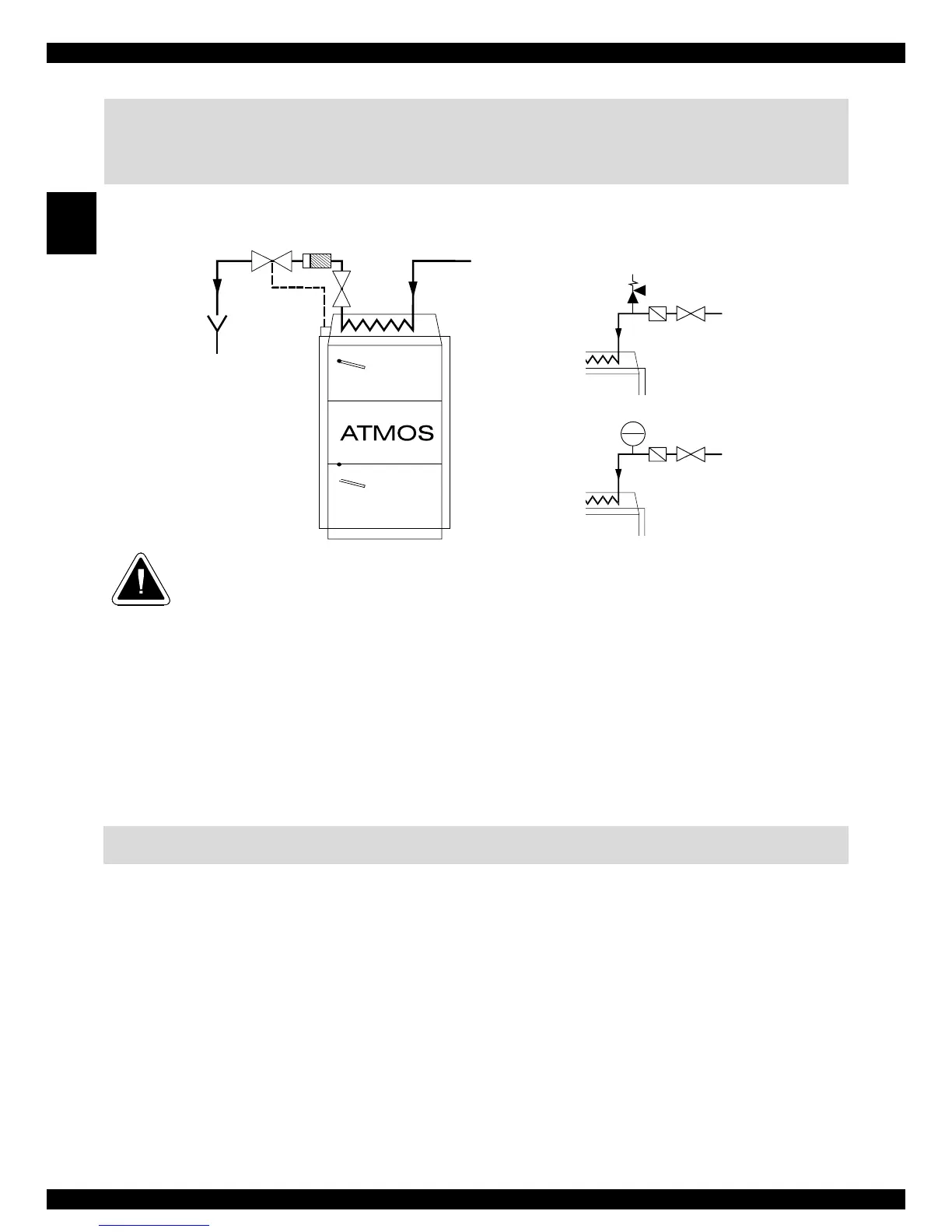

26. Connection of overheat protecting cooling loop with a safe-

ty valve Honeywell TS 131 - 3/4 ZA or WATTS STS20

(valve opening temperature 95 - 97 °C)

ATTENTION – cooling loop to prevent overheating must be used in compliance with EN

ČSN 303-5 only for overheating prevention (never for heating up warm service water).

The TS 131 - 3/4 ZA or WATTS STS 20 valves, the sensor of which is placed in the rear of the

boiler, prevent overheating in the following way: if the boiler water temperature rises above 95 °C,

the valve opens and allows water from public water supply system to enter the cooling loop. This

water then absorbs the excessive energy and exits to the sewer. In case that a non-return flap valve has

been installed to the cooling loop water inlet for the purpose of preventing reversed water flow (which

might be caused by pressure drop in the public water supply system), the cooling loop must be fitted

with a 6 – 10 bar safety valve or with an expansion vessel of minimum 4 l volume. The boiler must

be protected against overheating at all times. If not, its damage or burst may occur.

27. Operating instructions

Preparing boilers for operation

Before putting boilers into operation, it is necessary to ensure that the system has been filled with

water, and air-bled. Wood boilers must be operated in compliance with the instructions stipulated in this

manual so that satisfactory and safe functioning is achieved. They can only be operated by adults.

Ignition and operation

Before fuel ignition, open the ignition valve /13/ by pulling the ignition valve pulling rod /17/ and

reduce the waste gas thermostat (DC15E excluded) for the ignition (to minimum - 0 °C). Through

the top door /2/ insert dry wood kindling on the heatproof shaped piece /5/. Place the kindling per-

pendicularly to the channel recess in the shaped piece so that a 2 – 4 cm gap between the recess and

fuel is created; which allows the waste gas passage. Place paper or wood wool on top of the kindling,

Honeywell TS 130– 3/4 A (95°C) valve

WATTS STS 20 (97°C)

sewer

filter

valve

water supply from

public water system

pressure: 2 - 6 bar

temperature: 10 – 15°C

safety valve 6 – 10 bar

non-return

flap valve

non-return

flap valve

expansion tank of min. 4 l volume

Loading...

Loading...