3. Remove the terminal cover. Isolate element wires from the terminal block and check

resistance with an ohmmeter. If there is resistance, no further action is needed. If

there is not any resistance, replacement is needed. Disconnect and mark the terminal

block for reassembly. It is important to straighten or cut o the loops at the end of the

element leads in order to prevent damage to the insulation cylinder when the leads are

pulled through it.

4. Mark the shell and end anges for easy assembly alignment. Remove the end ange

closest to the burned-out element. Carefully remove the end ange and end disk.

5. Carefully feed the element lead wires through the shell while removing the defective

element from its seat. Be careful not to damage the insulation.

6. If necessary, straighten the new wire leads. Align the wires with the wire paths in the

insulation and feed the wires through the shell by inserting a guide tube into the wire

path and pushing the wire through the guide tube, or by putting a string through the

hole, tying it to the wire, and pulling it through the wire path.

7. Place the wires to maintain the maximum distance between them. Carefully position the

element in place. Align any ports if applicable.

8. After installing the new element, insert the thermocouple to ensure alignment.

9. Install the insulation end disk. Align

the end ange with the shell and install

it. If necessary, a bar clamp can be

used to gently compress the assembly

enough to align the screw holes.

10. Ensure that the leads do not short-

circuit against the outside case.

11. Use a ohmmeter to check for short

circuits. Install the terminal block and

attach the wires. Cut o any excess

wires. Check again for short circuits

and correct any problems before

completing the installation.

12. Inspect the embedding material for

cracks or damage. If the embedding

must be repaired, refer to the

Embedding & Patching Elements

(Section G.2, p. 13)

Series 31XX, 32XX Furnaces | G. Furnace and Element Maintenance 17

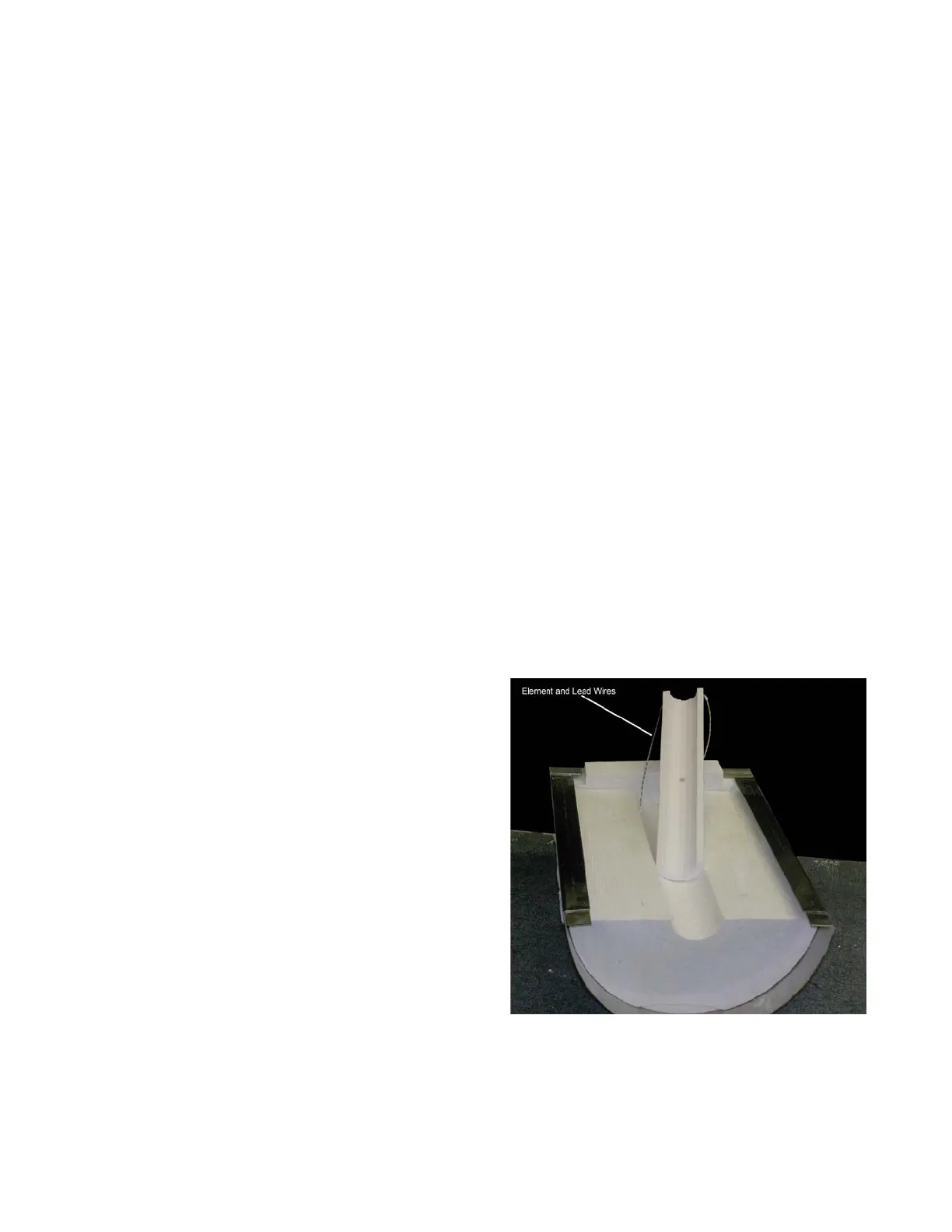

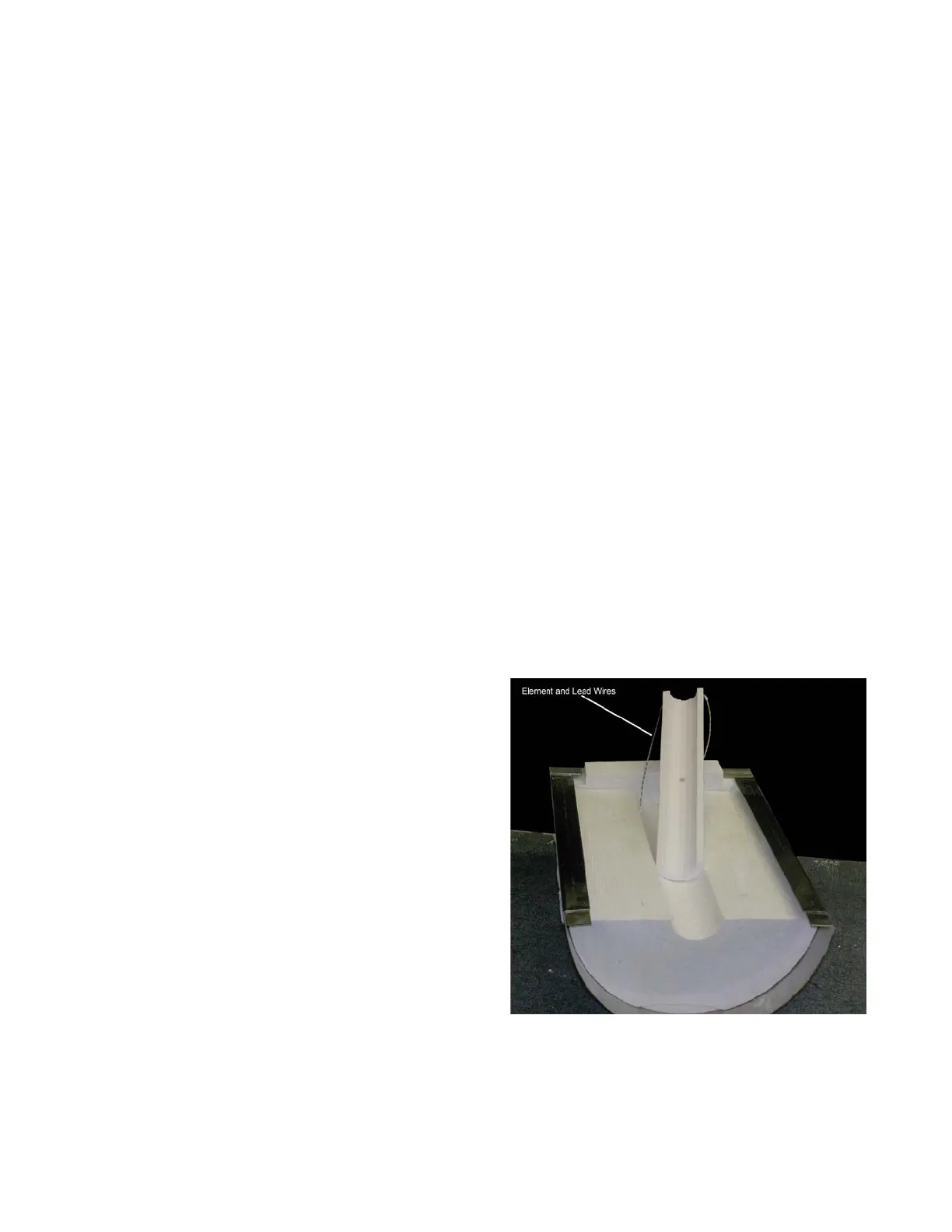

Figure G.4 - Safe Distance Between Lead Wires

Loading...

Loading...