16 Series 31XX, 32XX Furnaces | G. Furnace and Element Maintenance

8. After installing the new element, insert the thermocouple to ensure alignment.

9. Install the insulation end disk. Align the end ange with the shell and install it. If

necessary, a bar clamp can be used to gently compress the assembly enough to align

the screw holes.

10. Ensure that the leads do not short circuit against the outside case.

11. Use an ohmmeter to check for short circuits. Install the terminal block and attach

the wires. Cut o any excess wires. Check again for short circuits, and correct any

problems before completing the installation.

12. Inspect the embedding material for cracks or damage. If the embedding must be

repaired, refer to the Embedding & Patching Elements section of this manual (Section

G.2, p. 13).

13. If applicable, mount the furnace on the testing machine. Connect the leads and

instrumentation, and install the terminal covers.

14. If any insulation has been replaced, follow the bake-out procedures outlined in the

furnace manual. Bake-out is not necessary unless the insulation has been replaced.

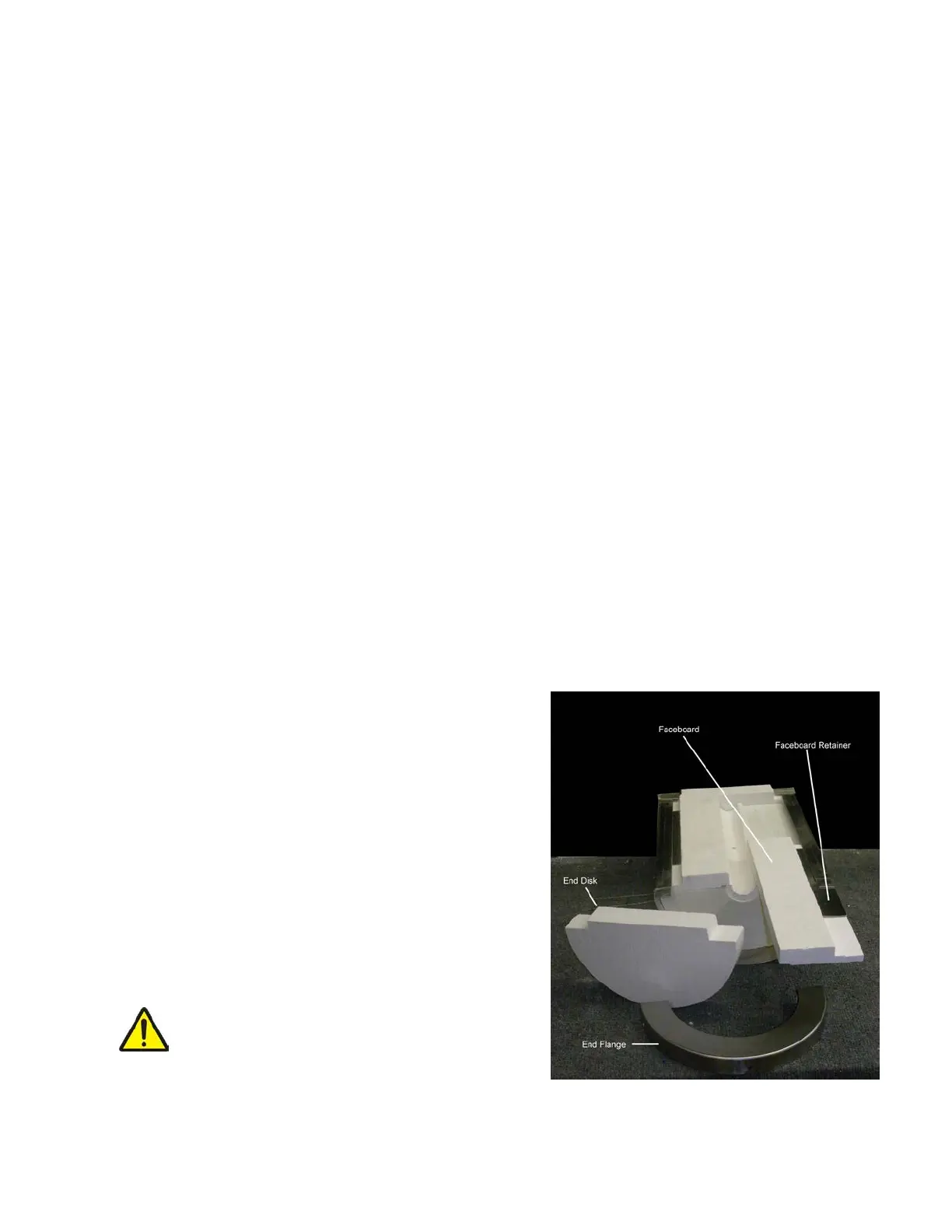

3210 Split Tube Furnace Element Replacement

The element replacement procedure described

in this section is for ATS Series 3210 Split Tube

Furnace types only. Refer to Figure G.3 for an

identication of parts.

1. Turn o furnace and allow to cool completely.

2. Disconnect the power and instrumentation

wiring from the furnace. If applicable, remove

the furnace from the testing machine and

position the furnace on the workbench in a

suitable cradle.

WARNING: Failure to completely

disconnect the furnace from the

power supply before attempting

disassembly may cause

personal injury or death.

Figure G.3 - Series 3210 Furnace

Loading...

Loading...