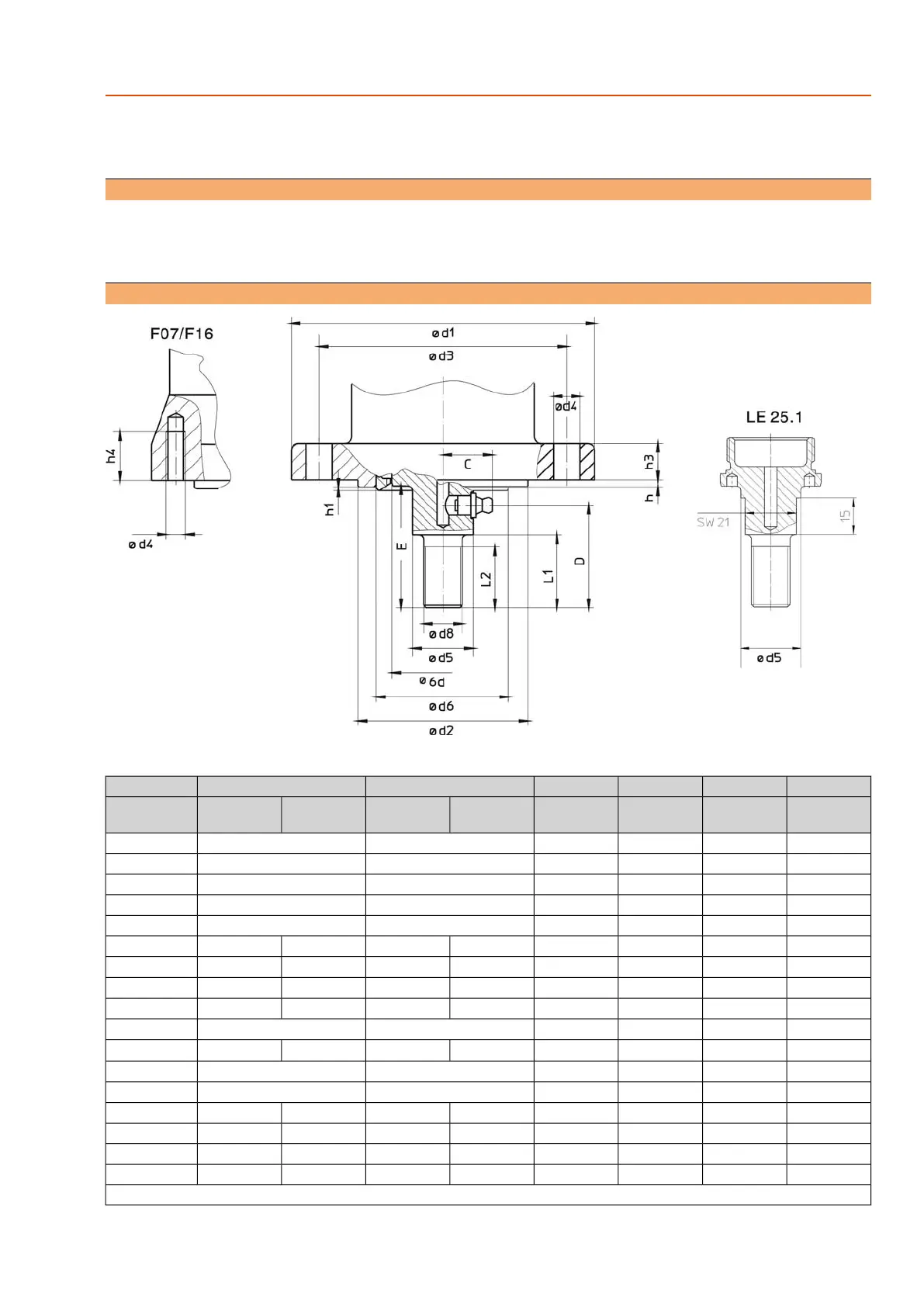

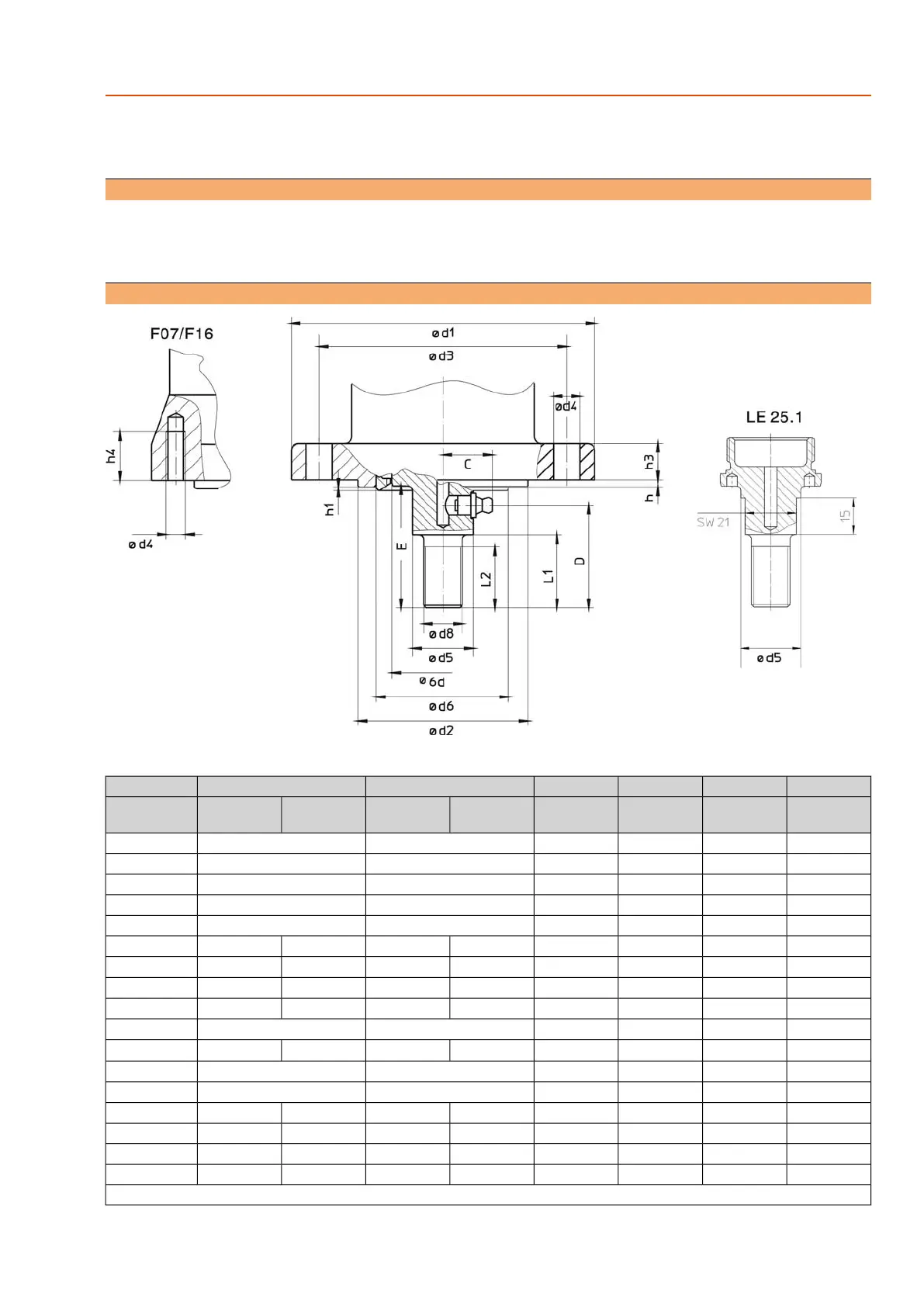

Mounting flange with 2 holes for pivots1)

Extension flange F16/25 max. input torque 1,000 Nm2)

4.3. Linear thrust unit: mount to valve

Mounting position

Mounting is most easily done with the valve shaft pointing vertically upward. But

mounting is also possible in any other position.

The linear thrust unit leaves the factory with retracted thrust rod (stem).

4.3.1. Attachment dimensions for mounting to valve

Table 3: Attachment dimensions to valve

LE 200.1LE 100.1LE 70.1LE 50.1LE 25.1LE 12.1Dimensions

F16

(G3)

F14

(G1/2)

F14

(G1/2)

F10

(–)

F10

(G0)

F07

(G0)

F10

(G0)

F07

(G0)

EN ISO 5210

(DIN 3210)

292626242118C

766363434237D

907575555045

E ±0.2

–––353025L1

655555302520L2

210175175125

1257512575∅ d1

130 f8100 f8100 f870 g770 f8(55 g7 = d6)70 f8(55 g7 = d6)

∅ d2

1651401401021027010270

∅ d3

M2018181111M811M8

∅ d4 (4x)

423636322520

∅ d5

120–––55

1)

–55

1)

–

∅ d6 g7

M42 x 3M36 x 3M36 x 3M20 x 1.5M16 x 1.5M12 x 1.25

∅ d8

1007070554242

∅ d9 –0.1

4443.433.433.4h

0.5–––0.5–0.5–h1

–18181515–15–h3

32––––20–20h4

Grease nipple A-D8 according to DIN 71412

11

LE 12.1 – LE 200.1

Assembly

Loading...

Loading...