Instructions for use in potentially explosive atmospheres of categories M2,

2G, 3G, 2D and 3D according to EU directive 94/9/EC

●

The technical data as well as the ambient temperatures, type of duty and running

times indicated on the name plate must imperatively be observed.

●

In hazardous areas where combustible dust is present in particular, perform

visual inspection for deposit of dirt or dust on a regular basis. Clean devices if

required.

6.3. Re-lubrication

Re-lubrication is only necessary if grease has been visibly leaking and can be

performed through the grease nipple while mounted.

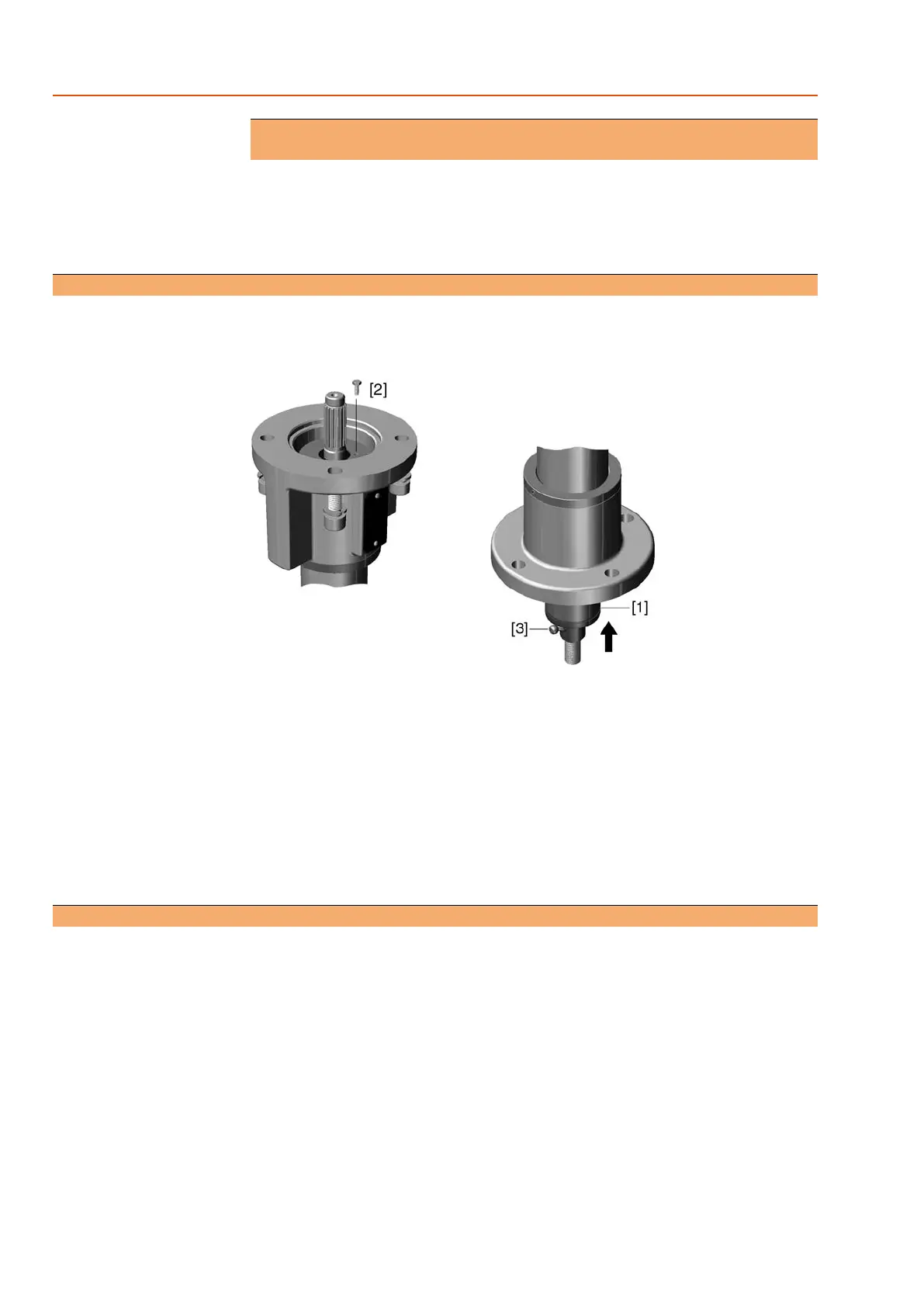

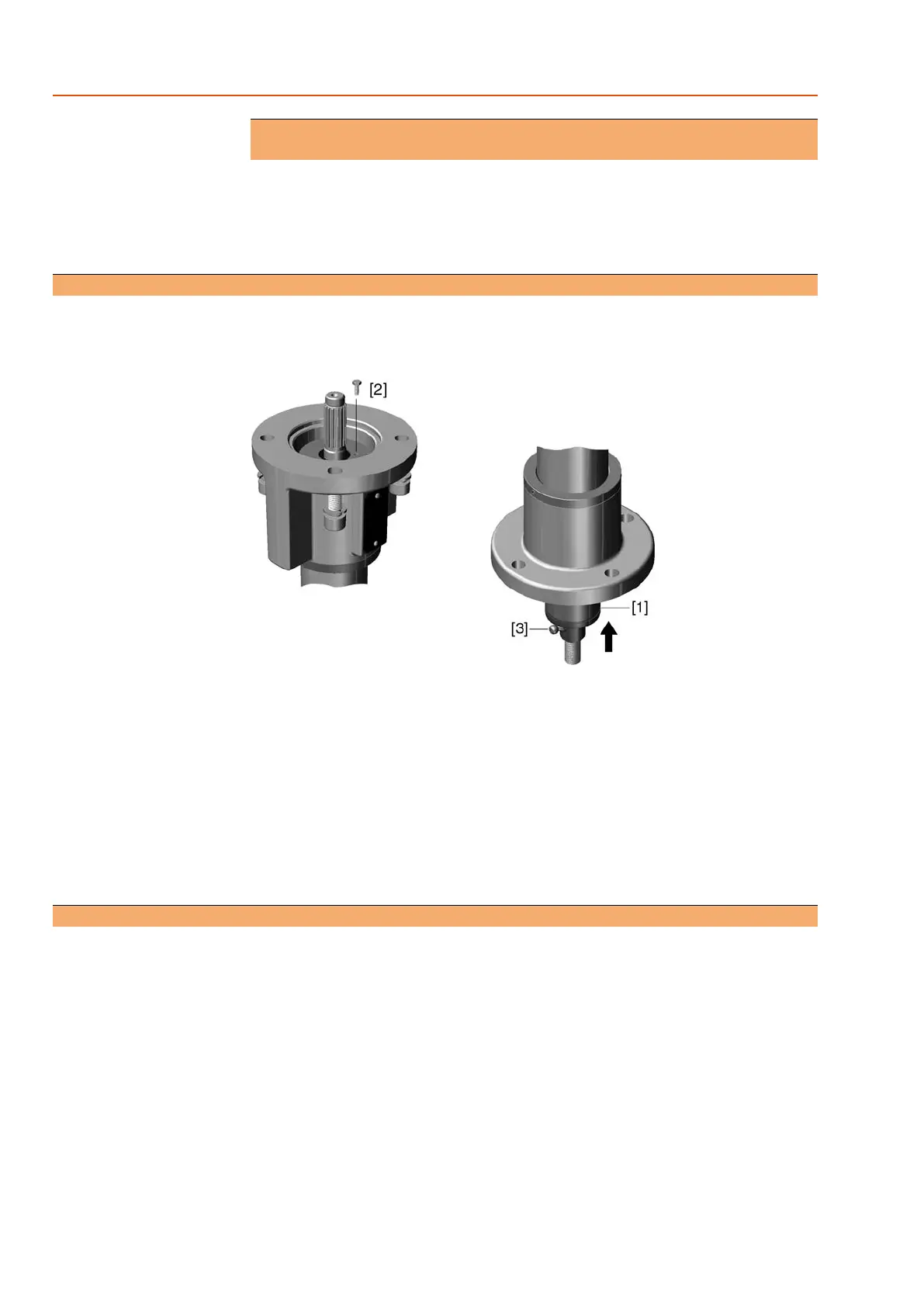

Figure5: Grease nipple and vent

[1] Inner tube

[2] Hexagonal screw for venting

[3] Grease nipple

1. Move inner tube [1] to upper position (retracted).

2. Remove multi-turn actuator from linear thrust unit.

3. Open vent hole by removing the hexagon screw [2].

4. Press grease into the grease nipple [3] with grease gun until grease emerges

from the vent hole of the hexagon screw [2].

5. Close vent hole again using hexagon screw [2].

6. Mount multi-turn actuator again to linear thrust unit.

6.4. Disposal and recycling

Our devices have a long lifetime. However, they have to be replaced at one point in

time.The devices have a modular design and may, therefore, easily be separated

and sorted according to materials used, i.e.:

●

electronic scrap

●

various metals

●

plastics

●

greases and oils

The following generally applies:

●

Greases and oils are hazardous to water and must not be released into the

environment.

●

Arrange for controlled waste disposal of the disassembled material or for sep-

arate recycling according to materials.

●

Observe the national regulations for waste disposal.

16

LE 12.1 – LE 200.1

Servicing and maintenance

Loading...

Loading...