7. Operation

7.1. Manual operation

For purposes of setting and commissioning, in case of motor or power failure, the

actuator may be operated manually. Manual operation is engaged by an internal

change-over mechanism.

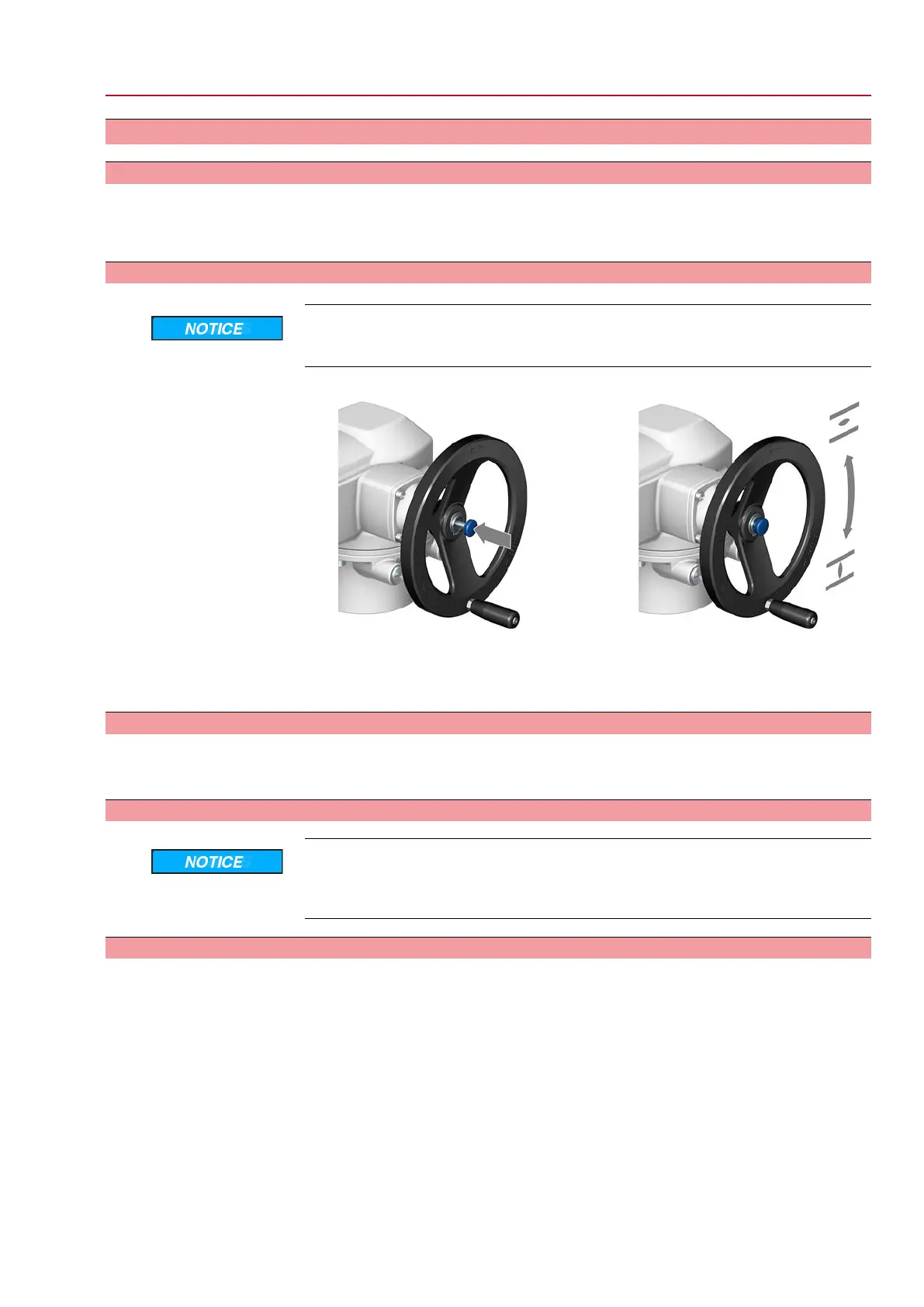

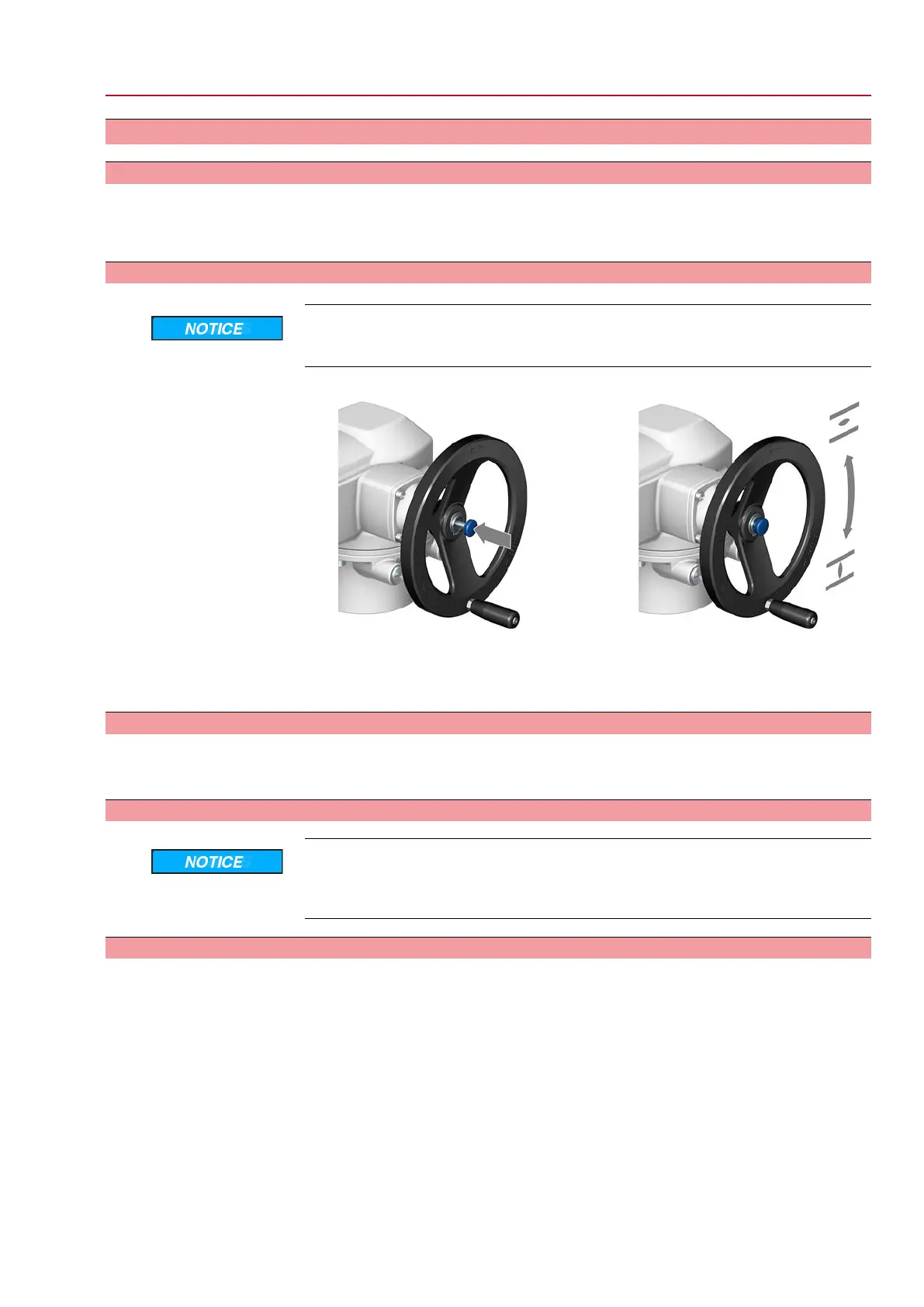

7.1.1. Manual operation: engage

Damage at the motor coupling due to faulty operation!

→

Engage manual operation only during motor standstill.

1. Press push button.

2. Turn handwheel in desired direction.

→

To close the valve, turn handwheel clockwise:

➥

Drive shaft (valve) turns clockwise in direction CLOSE.

7.1.2. Manual operation: disengage

Manual operation is automatically disengaged when motor is started again. The

handwheel does not rotate during motor operation.

7.2. Motor operation

Valve damage due to incorrect basic setting!

→

Prior to electric actuator operation, perform the basic settings for “type of seating”

and “torque switching”.

7.2.1. Operating the actuator from local controls

Local actuator operation is performed using the local controls push buttons of actuator

controls.

33

SQV 05.2 – SQV 14.2 / SQRV 05.2 – SQRV 14.2 Control unit: electronic (MWG)

ACV 01.2 Non-Intrusive Profibus DP Operation

Loading...

Loading...