THE IGNITION SYSTEM

Cleaning the Distributor; Lubrication

Fault Finding

11

T

HE C,illgnition Equipment is provided with an automati.c advance

mechanism, which relieves the driver of the necessity of constant

adiustment of the hand ignition controL Its advantages are par-

ticularly evident when accelerating, and during hill climbing, the danger

of pre-ignition, knocking or "pinking" being very much reduced.

The device is housed in the distributor body and it consists of a

;entrilugally operated mechanism by means of which the ignition is

advanced in proportion to the engine speed. .

Very little attention is needed to keep the ignition equipment in

first-class condition; we advise that it is inspected occasionally and the

following instructions on lubrication, cleaning and adjustment should be

carried out.

I

The Contacts,

11

E

:1

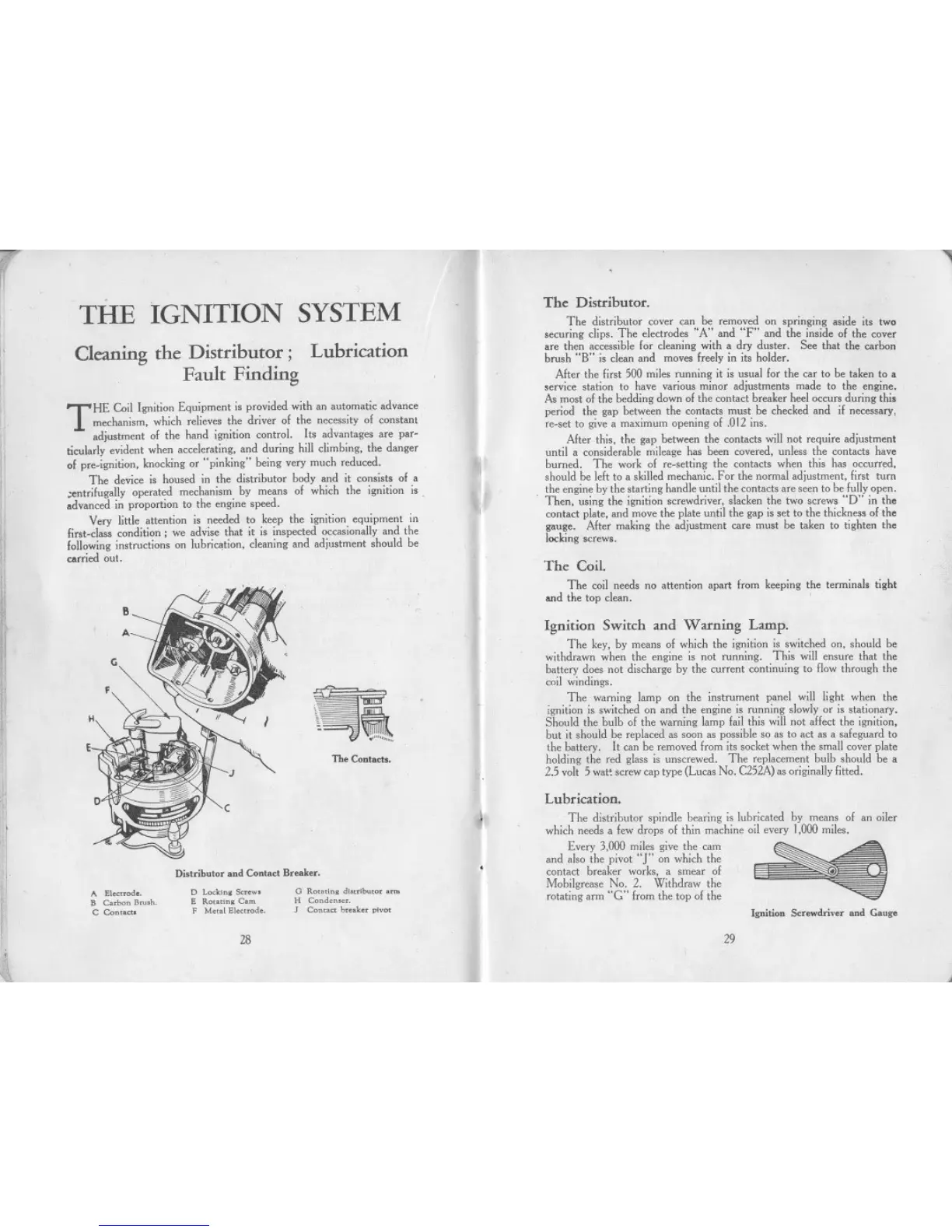

Di,tributor and Contact Breaker.

I"

A EI",rod..

B Cubon BMh.

C Con"'"

D Lo,ki.. Smw.

E Row'n, C,rn

FM.", EI.mod..

G Row'n, d",ribu,o, .=

H Cond.no".

J Con"" bmk" plvp,

28

~\

I"

1:

"

The Distributor,

The distributor cover can be removed on springing aside its two

securing clips. The electrodes "A" and "F" and the inside of the cover

are then accessible for cleaning with a dry duster. See that the carbon

brush "B" is clean and moves freely in its holder.

After the first 500 miles running it is usual for the car to be taken to a

service station to have various minor adjustments made to the engine.

As most of the bedding down of the contact breaker heel occurs during this

period the gap between the contacts must be checked and if necessary,

re-set to give a maximum opening of .012 ins.

After this, the gap between the contacts will not require adjustment

until a considerable mileage has been covered, unless the contacts have

burned. The work of re-setting the contacts when this has occurred,

should be left to a skilled mechanic. For the normal adjustment, first turn

the engine by the starting handle until the contacts are seen to be fully open.

. Then, using the ignition screwdriver, slacken the two screws "D" in the

contact plate, and move the plate until the gap is set to the thickness of the

gauge. After making the adjustment care must be taken to tighten the

locking screws.

The CoiL

The coil needs no attention apart from keeping the terminals tight

and the top clean.

Ignition Switch and Warning Lamp.

The key, by means of which the ignition is switched on. should be

withdrawn when the engine is not running. This will ensure that the

battery does not discharge by the current continuing to flow through the

coil windings.

The warning lamp on the instrument panel will light when the

ignition is switched on and the engine is running slowly or is stationary.

Should the bulb of the warning lamp fail this will not affect the ignition,

but it should be replaced as soon as possible so as to act as a safeguard to

the battery. It can be removed from its socket when the small cover plate

holding the red glass is unscrewed. The replacement bulb should be a

2.5 volt 5 wat' screw cap type (Lucas No. C252A) as originally fitted.

Lubrication.

The distributor spindle bearing is lubricated by means of an oiler

which needs a few drops of thin machine oil every 1,000 miles.

Every 3,000 miles give the cam

and also the pivot "r on which the

contact breaker works, a smear of

Mobilgrease No. 2. Withdraw the

rotating arm "C" from the top of the

~

Ignition Screwdriver and Gauge

29

,

Loading...

Loading...