...",.

,

RUNNING ADJUSTMENTS

dropped on a "live" wire or terminal,

thu" causing a short and possible

edamage. Therefore disconnect the

battery cable at the battery for safety.

First drain the water through

the tap under the radiator. Detach

the top water tube from the head.

Disconnect the high tension wires

from the sparking plugs. Remove

the nuts holding down the head.

Then take hold of the head at each

end and lift it off.

This should be fairly easy to do,

without damaging the joint washer

or gasket. which. in the ordinary

course, may be in a condition to be

used again.

If it is damaged or otherwise not

in good condition the gasket should

be replaced by a new one.

Decarbonising; Valve Grinding; Tappet

Adjustment

,

T

HE adjustments set out below

are all that the owner will find

it necessary to make to keep the

<:arin good running order.

Unless the work i~ thoroughly

understood. however. it is strongly

recommended that the car be taken

to an Austin Dealer. .

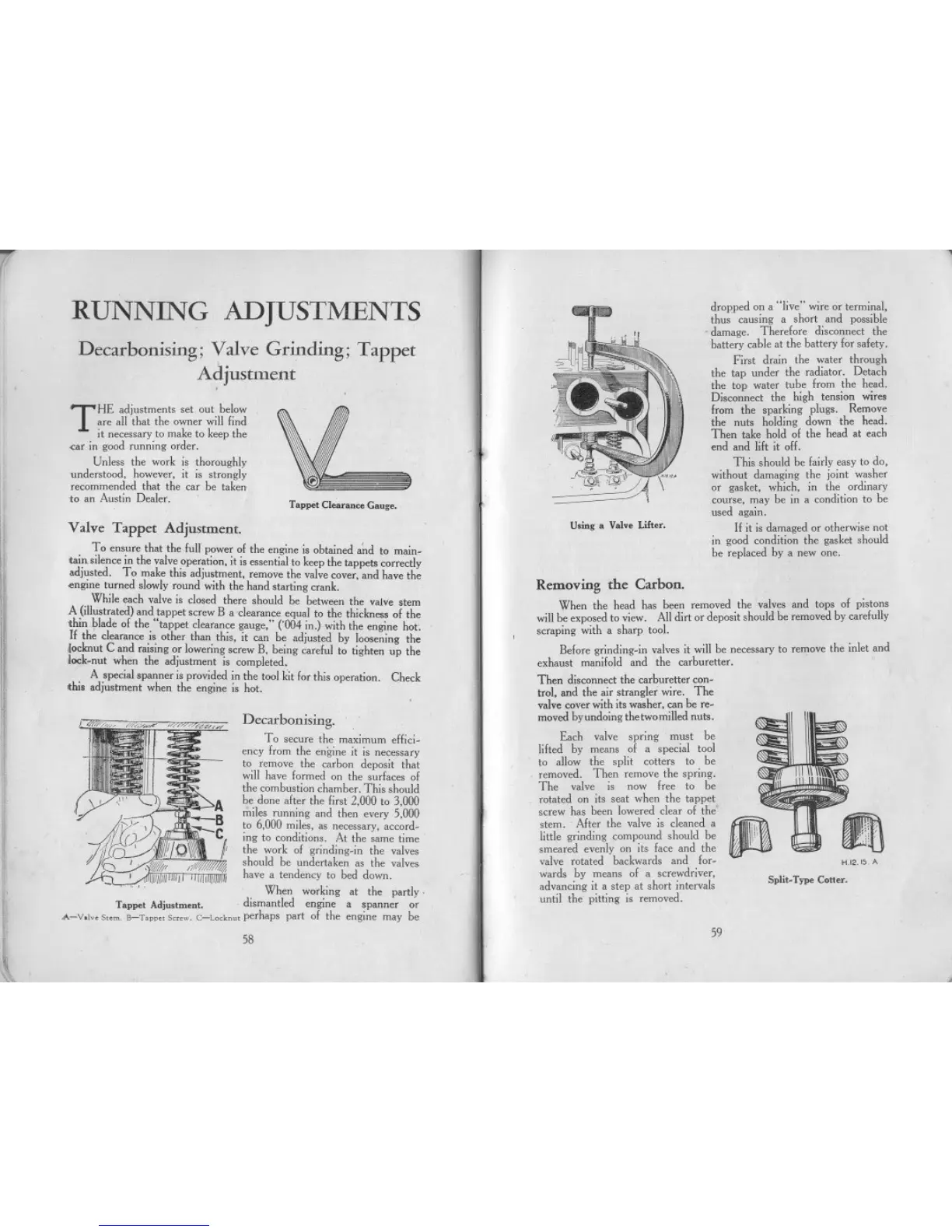

Tappet Clearance Gange.

Us;"g . Valve Lifter.

Valve Tappet Adjustment.

To ensure that the full power of the engine is obtained ';'d to main-

tair"ilence in the valve operation, it is essential to keep the tappets correctly

adjusted. To make this adjustment, remove the valve cover. and have the

"ngine turned slowly round with the hand starting crank.

While each valve is closed there should be between the valve stem

A (illustrated) and tappet screw B a clearance equal to the thickness of the

thin blade of the "tappet clearance gauge," ('004 in.) with the engine hot.

If the clearance is other than this. it can be adjusted by loosening the

locknut C and raising or lowering screw B. being careful to tighten up the

lock-nut when the adjustment is completed.

A special spanner is provided in the tool kit for this operation. Check

this adjustment when the engine is hot.

f

I

Removing the Carbon.

When the head has been removed the valves and tops of pistons

will be exposed to view. All dirt or deposit should be removed by carefully

scraping with a sharp tool.

Before grinding-in valves it will be necessary to remove the inlet and

exhaust manifold and the carburetter.

Then disconnect the carburetter con-

trol, and the air strangler wire. The

valve cover with its washer, can be re-

moved byundoingthetwomilled nuts.

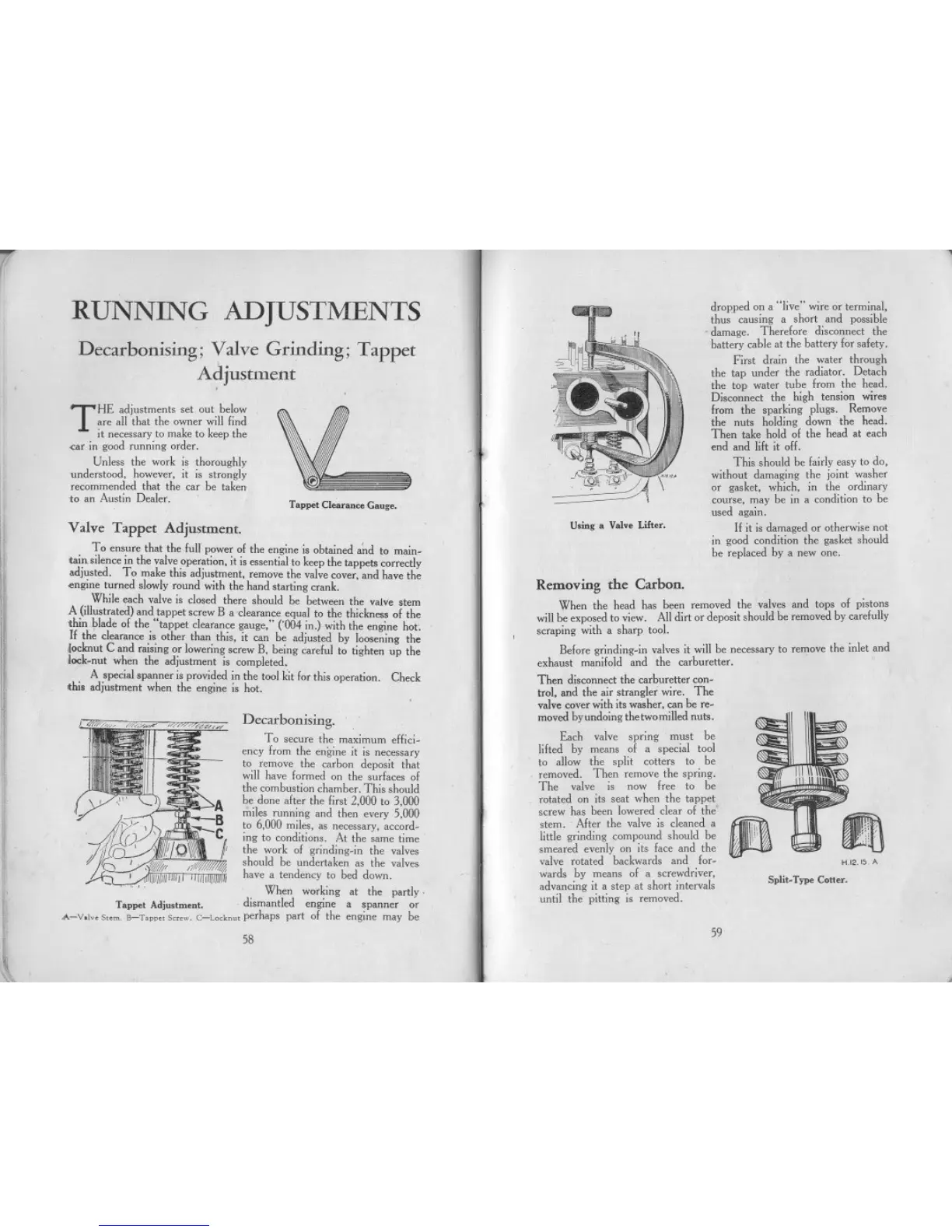

Each valve spring must be

lifted by means of a special tool

to allow the split cotters to be

removed. Then remove the spring.

The valve is now free to be

rotated on its seat when the tappet

screw has been lowered clear of the

stem. After the valve is cleaned a

little grinding compound should be

smeared evenly on its face and the

valve rotated backwards and for-

wards by means of a screwdriver.

advancing it a step at short intervals

until the pitting is removed.

I

I

I

I

,

I

1

I

I

I

I

I

Decarbonising. '.

To secure the maximum effici-

ency from the engine it is necessary

to remove the carbon deposit that

will have formed on the surfaces of

the combustion chamber. This should

be done after the first 2,000 to 3.000

miles running and then every 5.000

to 6.000 miles, as necessary. accord-

ing to conditions. At the same time'

the work of grinding-in the valves

should be undertaken as the valves

have a tendency to bed down.

When working at the partly.

Tappet Adjustment. dismantled engine a spanner or

;'-V.lv< S"rn. B-T.p", Smw. C-Lockno'perhaps part of the engine may be

H.I2.'5. A

Split-Type Cotter.

59

58

" ,

Loading...

Loading...