T

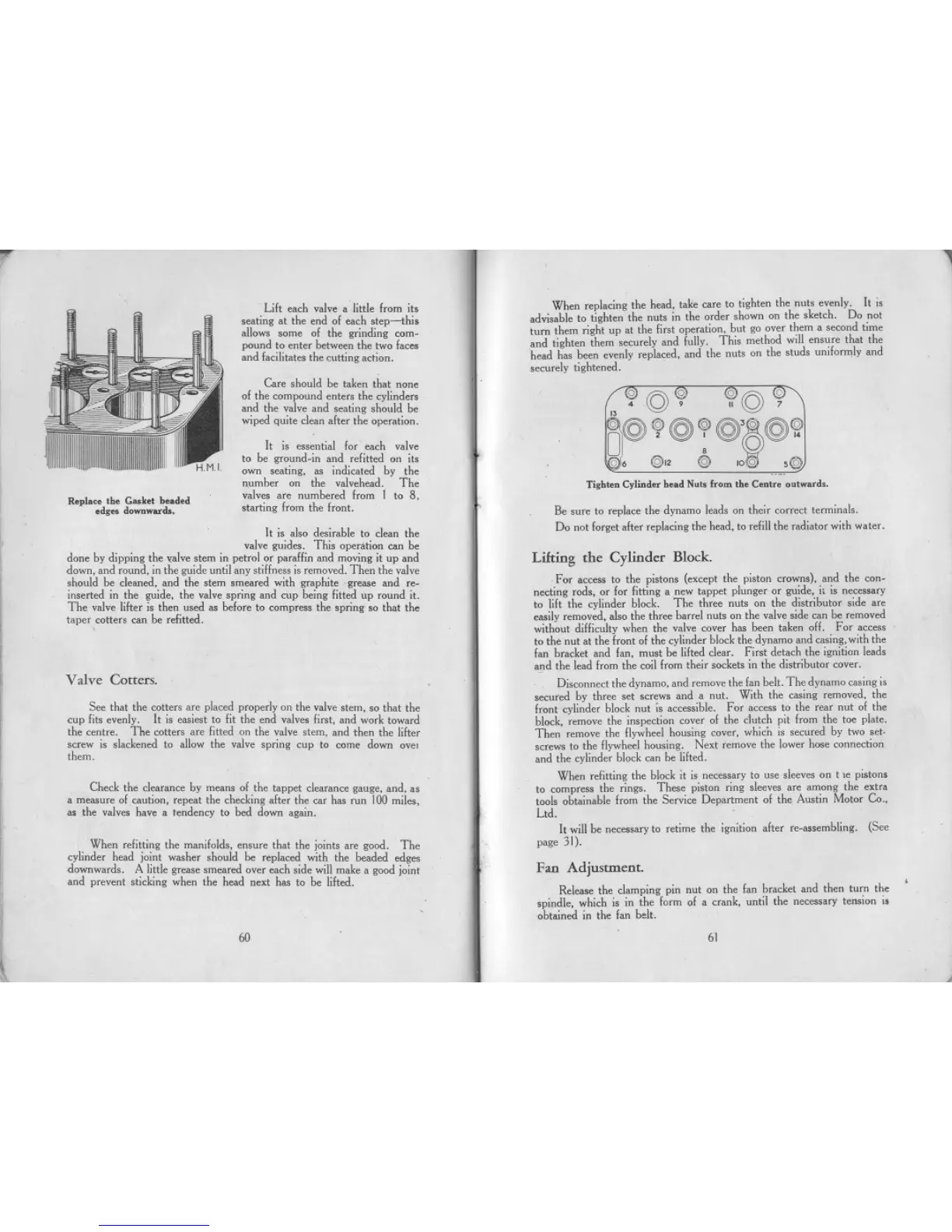

Replace the Gasket headed

ed... downwards.

1

Lift each valve a little from its

seating at the end of each step-this

allows some of the grinding com-

pound to enter between the two faces

and facilitates the cutting action.

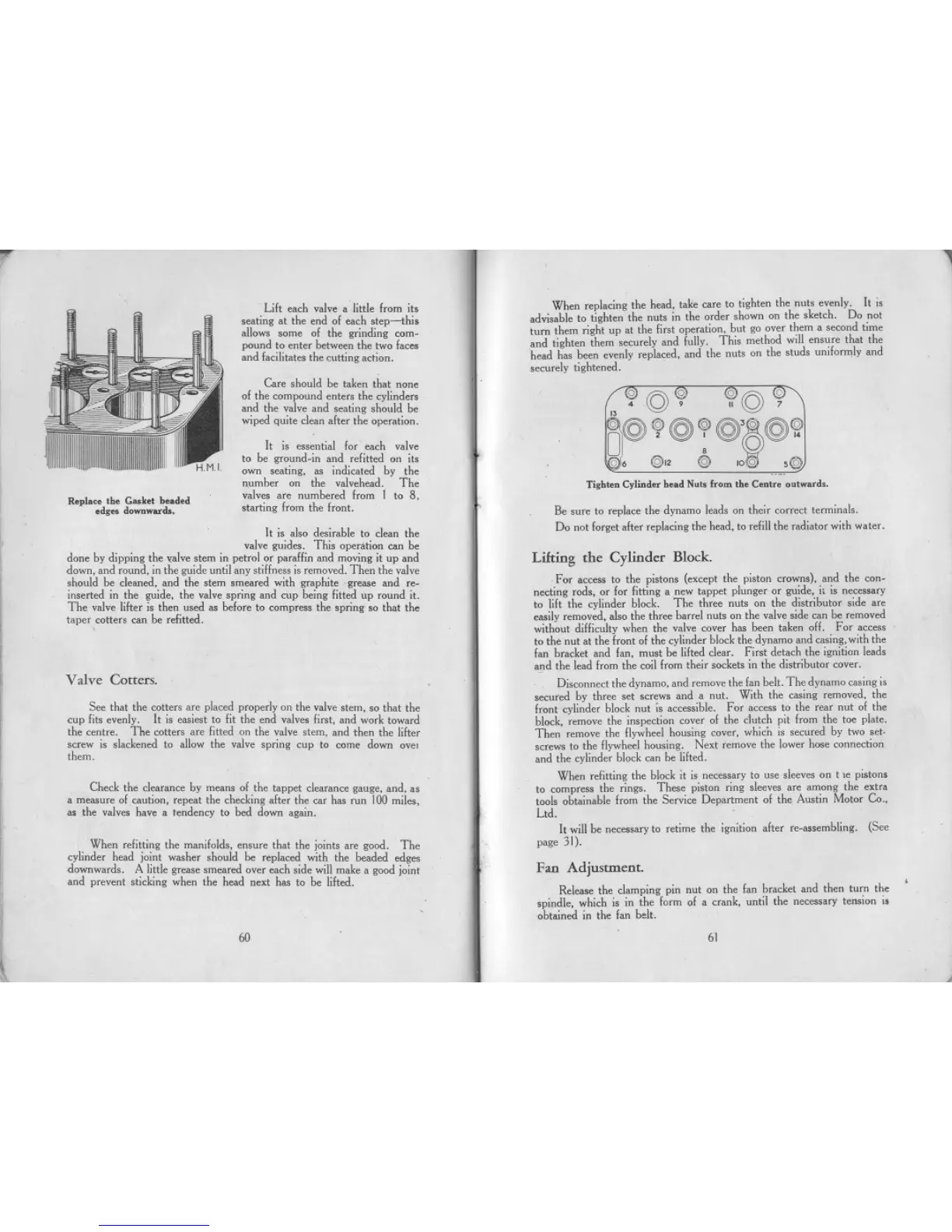

When replacing the head. take care to tighten the nuts evenly. It is

advisable to tighten the nuts in the order shown on the sketch. Do not

turn them right up at the first operation. but go over them a second time

and tighten them securely and fully. This method will ensure that the

head has been evenly replaced. and the nuts on the studs uniformly and

securely tightened.

Care should be taken that none

of the compound enters the cylinders

and the valve and seating should be

wiped quite clean after the operation.

It is essential for' each valve

to be ground-in and refitted on its

own seating. as indicated by the

number on the valvehead. The

valves are numbered from I to 8.

starting from the front.

Tighten Cylinder head Nuts Irom the Centre outwards.

Be sure to replace the dynamo leads on their correct terminals.

Do not forget after replacing the head. to refill the radiator with water.

It is also desirable to clean the

valve guides. This operation can be

done by dipping the valve stem in petrol or paraffin and moving it up and

down. and round. in the guide until any stiffness is removed. Then the valve

should be cleaned. and the stem smeared with graphite grease and re-

inserted in the guide. the valve spring and cup being fitted up round it.

The valve lifter is then used as before to compress the spring so that the

taper cotters can be refitted.

Valve Cotters.

Lifting the Cylinder Block.

. For access to the pistons (except the piston crowns). and the con-

necting rods. or for fitting a new tappet plunger or guide. it is necessary

to lift the cylinder block. The three nuts on the distributor side are

easily removed. also the three barrel nuts on the valve side can be removed

without difficulty when the valve cover has been taken off. For access

to the nut at the front of the cylinder block the dynamo and casing. with the

fan bracket and fan. must be lifted clear. First detach the ignition leads

and the lead from the coil from their sockets in the distributor cover.

. Disconnect the dynamo. and remove the fan belt. The dynamo casing is

secured by three set screws and a nut. With the. casing removed. the

front cylinder block nut is accessible. For access to the rear nut of the

block. remove the inspection cover of the clutch pit from the toe plate.

Then remove the flywheel housing cover. whicn is secured by two set.

screws to the flywheel housing. Next remove the lower hose connection

and the cylinder block can be lifted.

When refitting the block it is necessary to use sleeves on t 1e pistons

to compress the rings. These piston ring sleeves are among the extra

tools obtainable from the Service Department of the Austin Motor Co..

Ltd.

It will be necessary to retime the ignition after re-assembling. (See

page 31).

See that the cotters are placed properly on the valve stem. so that the

cup fits evenly. It is easiest to fit the end valves first. and work toward

the centre. The cotters are fitted on the valve stem. and then the lifter

screw is slackened to allow the valve spring cup to come down ove,

them.

Check the clearance by means of the tappet clearance gauge, and, as

a measure of caution. repeat the checking after the car has run 100 miles.

as the valves have a tendency to bed down again.

When refitting the manifolds. ensure that the joints are good. The

cylinder head joint washer should be replaced with the beaded edges

downwards. A little grease smeared over each side will make a good joint

and prevent sticking when the head next has to be lifted.

Pan Adjustment.

Release the clamping pin nut on the fan bracket and then turn the

spindle. which is in the form of a crank. until the necessary tension is

obtained in the fan belt.

60 61

)

Loading...

Loading...