--;>

~

spindle by lifting it off and add a few drops of thin oil to the top of .the

spindle. Do not remove the screw exposed to view, as tbere is a clearance

between the screw and the inner face of the spindle tbrough which the oil

passes to luhricate tbe cam bearing. Take care to refit the arm correctly and

to push it on to the shaft as far as possihle.

The moving parts of tbe automatic timing control must he lubricated

with a good grade thin engine oil. To render the control accessible,

remove the distributor moulding and lift off the rotating distributor arm.

Then remove the contact hreaker moulding by withdrawing its two

securing screws. Take care to refit the contact hreaker moulding in its

original position. .

11

11

High Tension Leads.

If the high tension cables show signs of perishing or crackmg, they

must be replaced. Use only 7 m.m. rubber covered ignition cable for all

higb tension leads.

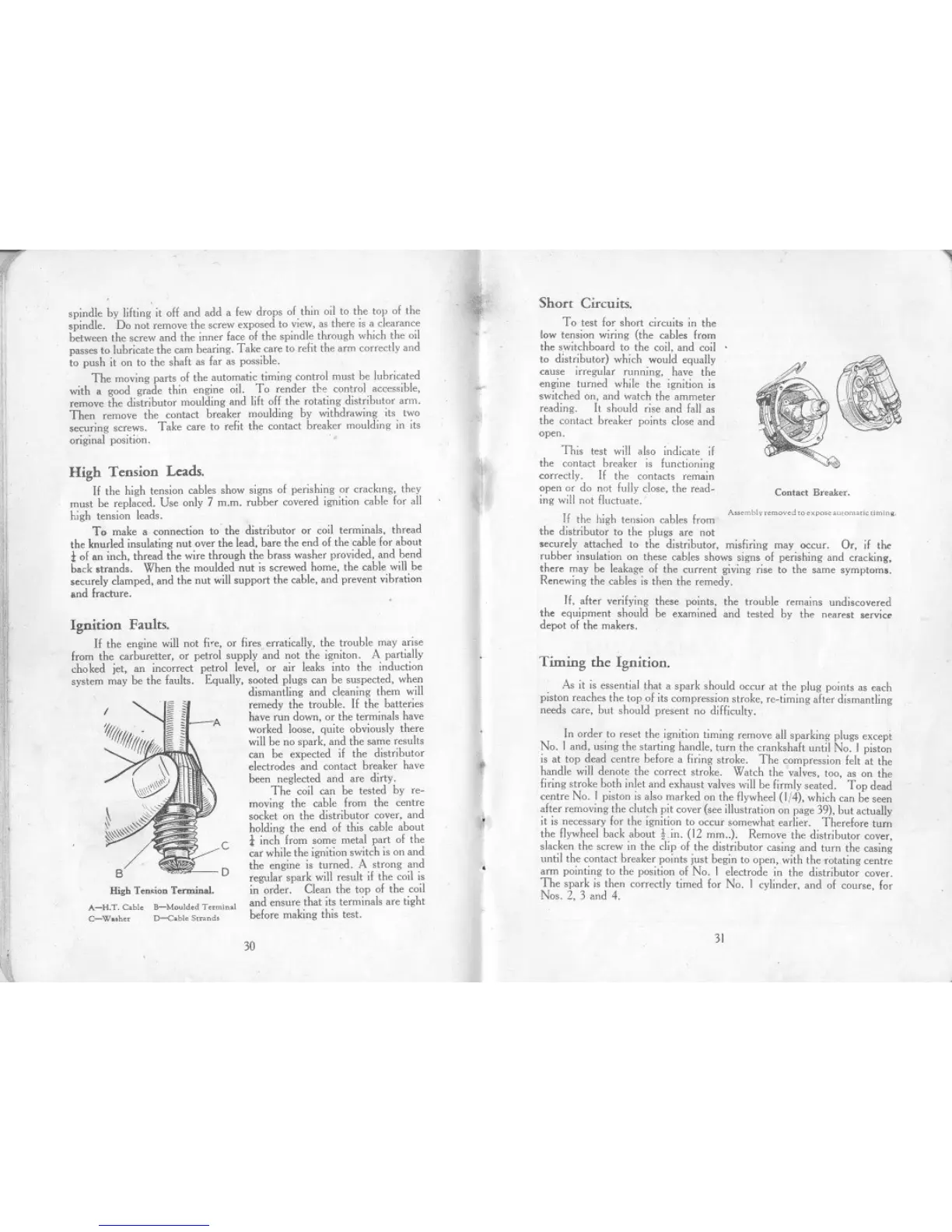

To make a connection to tbe distributor or coil terminals. thread

the knurled insulating nut over the lead, bare the end of the cable for about

1of an inch, thread tbe wire tbrough the hrass washer provided, and bend

back .trand" When the moulded nut is screwed home, the cable will be

.ecurely clamped, and the nut will support the cable, and prevent vibration

and fracture.

il

il~i

Ignition Faults.

If the engine will not fi<e, or fires erratically, the trouhle may arise

from the carhuretter, or petrol supply.and not the igniton. A partially

choked jet, an incorrect petrol level, or air leaks into the induction

system may be tbe faults. Equally, sooted plugs can be suspected, when

dismantling and cleaning them will

remedy the trouble. If the batteries

have run down, or the terminals have

worked loose, quite obviously there

will be no spark, and the same results

can be expected if the distributor

electrodes and contact hreaker have

been neglected and are dirty.

The coil can be tested by re-

moving the cable from the centre

socket on the distributor cover, and

holding the end of this cable ahout

1inch from some metal part of the

car while the ignition switch is on and

the engine is turned. A strong and

regular spark will result if the coil is

in order. Clean the top of the coil

A-H.T. C,bl, B-Mould,dT,=io,l and ensure thatit~ terminals are tight

C-Wuh" D-C,bl, S,mod. before making thIS test.

Ii

D

I

cH

'

!

"

I

111

,'"

I:j~ c

,~~

,."

High Temion Terminal.

il

,

'

'I

"

:,

30

l

B;

I

po'

I

'i.

I

il,

"

.

i

'j

,

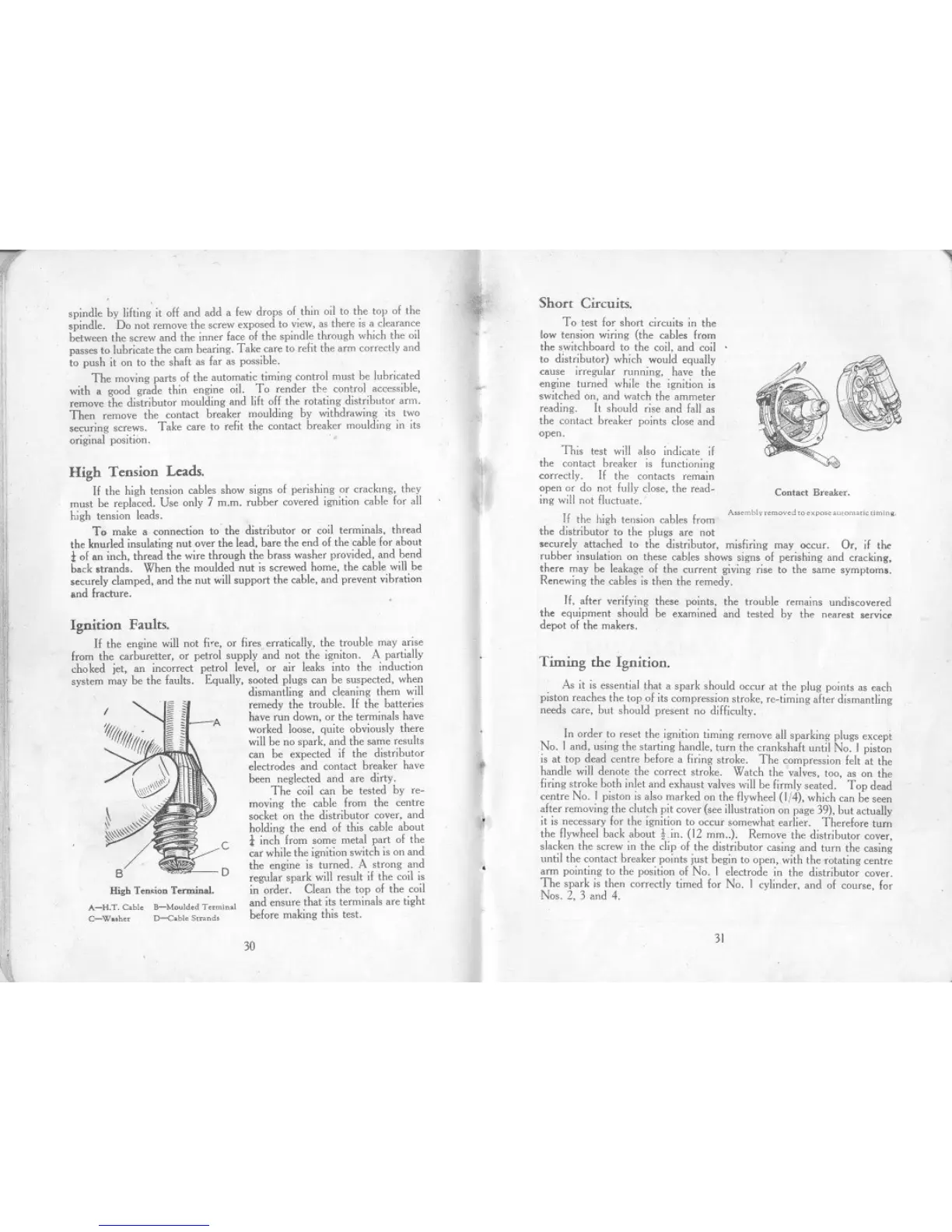

Short Circuits.

To test for short circuits in the

Iow tension wiring (the cables from

the switcbboard to the coil, and coil .

to distributor) which would equally

cause irregular running, have the

engine turned while the ignition is

switched on, and watch the ammeter

reading. It should rise and fall as

the contact breaker points close and

open.

This test will also indicate if

the contact breaker is functioning

correctly. If the contacts rcmain

open or do not fully close, the read-

ing will not fluctuate.

I

. .

I f

A..,mbl",mo"d<O"'O".u<om"',"m'o,.

f the high tension cab es ram

the distributor to the plugs are not

.ecurely attached to the distributor, misfiring may occur. Or, if the

rubber insulation on these cables shows signs of perishing and cracking,

there may be leakage of the current giving rise to the same symptom..

Renewing the cables is then the remedy.

If, after verifying the,e points, the trouble remains undiscovered

the equipment should be examined and tested by the nearest service

depot of the makers.

Contact Breaker.

Timing the Ignition.

As it is essential that a spark should occur at the plug points as each

piston reaches the top of its compression stroke, re-timing after dismantling

needs care, but should present no difficulty.

In order to reset the ignition timing remove all sparking plugs excepi

No. I and, using the starting handle, turn the crankshaft until No. I piston

is at top dead centre before a firing stroke. The compression felt at the

handle will denote the correct stroke. Watch the valves, too, as on the

firing stroke both inlet and exhaust valves will be firmly seated. Top dead

centre No. I piston is also marked on the flywheel (1/4), which can be seen

after removing the clutch pit cover (see illustration on page 39), but actually

it is necessary for the ignition to occur somewhat earlier. Therefore turn

the flywheel back about t.in. (12 mm..). Remove the distributor cover,

slacken the screw in the clip of the distributor casing and turn the casing

until the contact breaker points just hegin to open, with the rotating centre

arm pointing to the position of No. I electrode in the distributor cover.

Tbe spark is then correctly timed for No. I cylinder, and of course, for

Nos. 2, 3 and 4.

31

Loading...

Loading...