Techniques

Dead Volume

Dead volume should be minimized in order to switch solutions as rapidly

as possible. Dead volume for this purpose refers to the volume between

the manifold (or Perfusion Pencil) and nal destination (perfusion

chamber, 96-well plate, etc.) A certain amount of time must pass for a new

liquid to clear the previous one from this nal piece of tubing. Solution

switching takes place at the manifold - assuming each channel’s tubing has

been primed (lled) from its valve to this point. Therefore, the manifold

should be positioned as close to the ultimate destination as possible, while

the valves can be some distance away. The micro-manifolds available

from AutoMate Scientic are designed to be inserted directly into orices

in some perfusion chambers. This absolutely minimizes dead volume –

resulting in bath switching times of under a second.

AutoMate Scientic Perfusion Systems may include a disposable ow

regulator which will increase dead volume if used improperly. The

regulator can either be eliminated if controlling ow rate is not necessary,

or positioned before the manifold to eliminate dead volume. However, this

second method only controls the ow rate of individual solutions (instead

of all solutions when located after the manifold). Therefore, the researcher

can either limit the ow of a single liquid, or purchase ow regulators

for each line.

A nal method for reducing dead volume is to use smaller bore tubing,

although this may also reduce ow rate resulting in the same switching

time as for larger tubing.

Small-bore PTFE Tubing

AutoMate Scientic’s micro-manifolds use

1

/

16

” tube ports which can

either be used with

1

/

16

” o.d. tubing, or enlarged up to

1

/

16

” i.d. tubing for

standard Tygon tubing. Please inquire about AutoMate Scientic’s PTFE

tubing and nut and ferrule valve ttings for small bore use. Also see the

micro-manifold instructions on page 12.

Cutting PTFE tubing at an angle and wetting it makes it easier to insert.

Backflow

When a manifold is used in a plumbing arrangement, none of its ports

can be left unconnected, or liquid will simply ow backwards out of the

opening. Small, green hose clamps are included with AutoMate Scientic

Perfusion System drippers which can be easily attached to short pieces

of tubing to act as plugs for unused holes. AutoMate Scientic also sells

manifold 'stoppers' for plugging unused manifold ports.

Likewise, one must be careful not to open any valve whose reservoir

is completely empty or inow tube is disconnected. Ordinary solution

pressure in other lines will force liquid back up the outow tubing,

through the valve, and either back into the reservoir or out the

disconnected inow onto the oor. Again, clamp-o any unused lines at

the manifold or be sure all valves are closed while changing connections.

Solution will quickly backow into empty tubes even when their valves are

closed because air is so compressible. Fill all tubes down to the manifold

or Perfusion Pencil with solution even if they are not being used.

AutoPrime

™

System

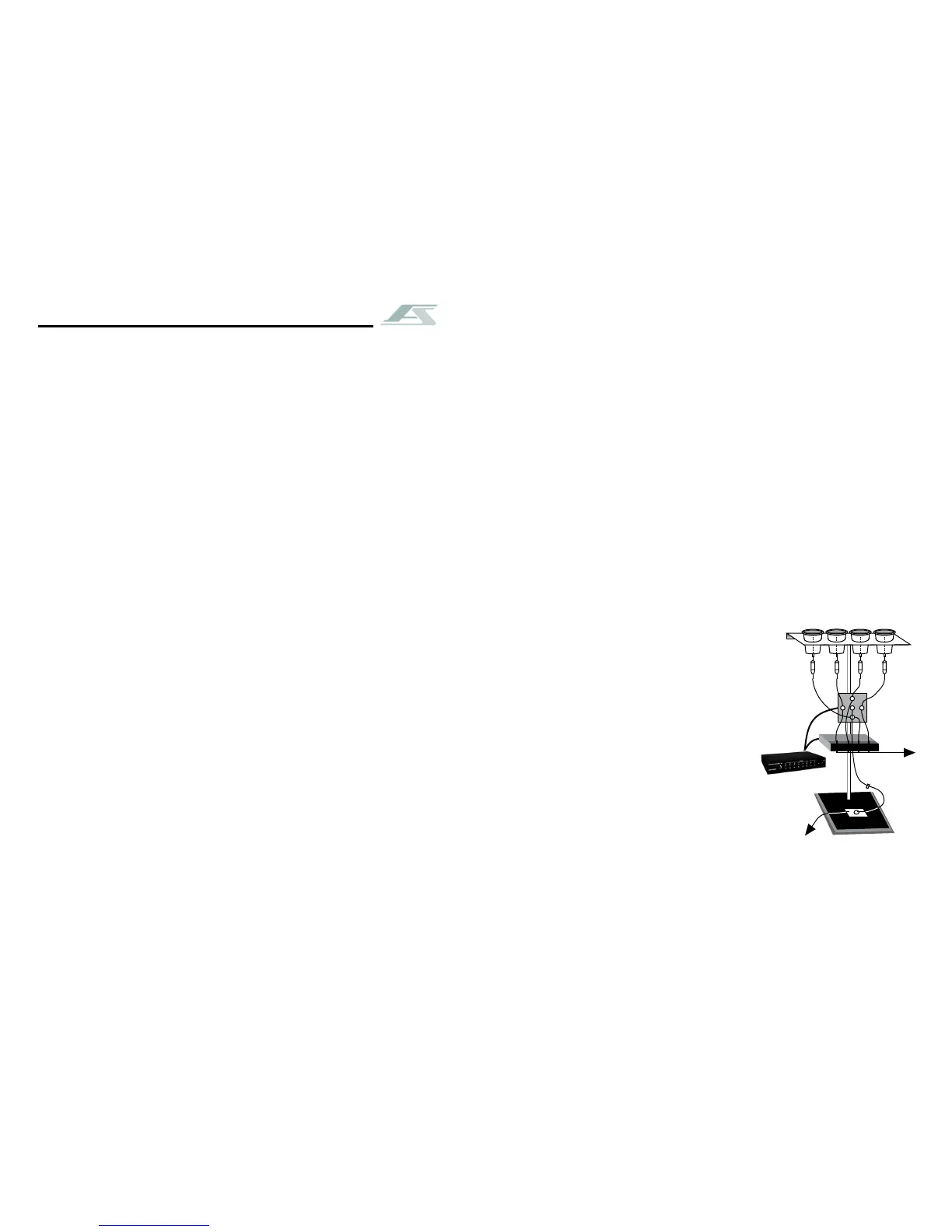

The AutoPrime Perfusion System is

designed to deliver oxygenated (or

other gas-saturated) solutions without

administering ‘stale’ liquid which has

remained stationary in the tubing long

enough to lose its oxygenation. Unless one

uses ‘hard-walled’ (i.e. PTFE) tubing, gas

will escape through the tubing leaving the

stale solution with a ruined pH and gas

concentration. The 8-channel AutoPrime

System uses eight valves per four liquids,

with the second set used as ‘ush’ valves

to waste. Shortly before a solution is to be

switched ‘on,’ its ush valve opens and re-

primes the upper tubing with fresh solution

from the reservoir down to its delivery

valve (where a tee tting is located connected to the ush valve.) The ush

valve is then closed, and the delivery valve can be opened. The previous

solution in a delivery sequence can continue to ow while re-priming

occurs. Contact AutoMate Scientic for more details.

waste

Loading...

Loading...