Drive pressure: There are

two checking points, on top of

the variable displacement pump

and under the variable displa-

cement pump. One tells the

pressure for forward driving,

the other for reverse driving.

When checking the pressure

the wheels must be locked e.g.

with the parking brake, engine

must run with full revs when

pressing the two drive pedals.

On models 520+, 523+,

528+ and 530+ the pressure

for boom lifting and auxiliary

hydraulics is checked and

adjusted separately. Pressure

for lifting is checked from the

manometer fitting, which is

located under the front cover

plate, beside the steering hyd-

raulic motor. Auxiliary hydrau-

lics pressure is checked by

mounting the manometer in

the female auxiliary hydraulics quick coupling, with

full revs and by turning the aux. hydraulics control lever.

It is recommended pressures should only be checked

by a competent and experienced technician

. Call

your AVANT dealer if you need assistance.

9. ADJUST PRESSURE OF HYDRAULIC

SYSTEM

If the pressure of hydraulic system does not seem to

be correct or pressure check indicates that the pressure

is wrong, it can be adjusted. Following table shows

pressure adjusting points.

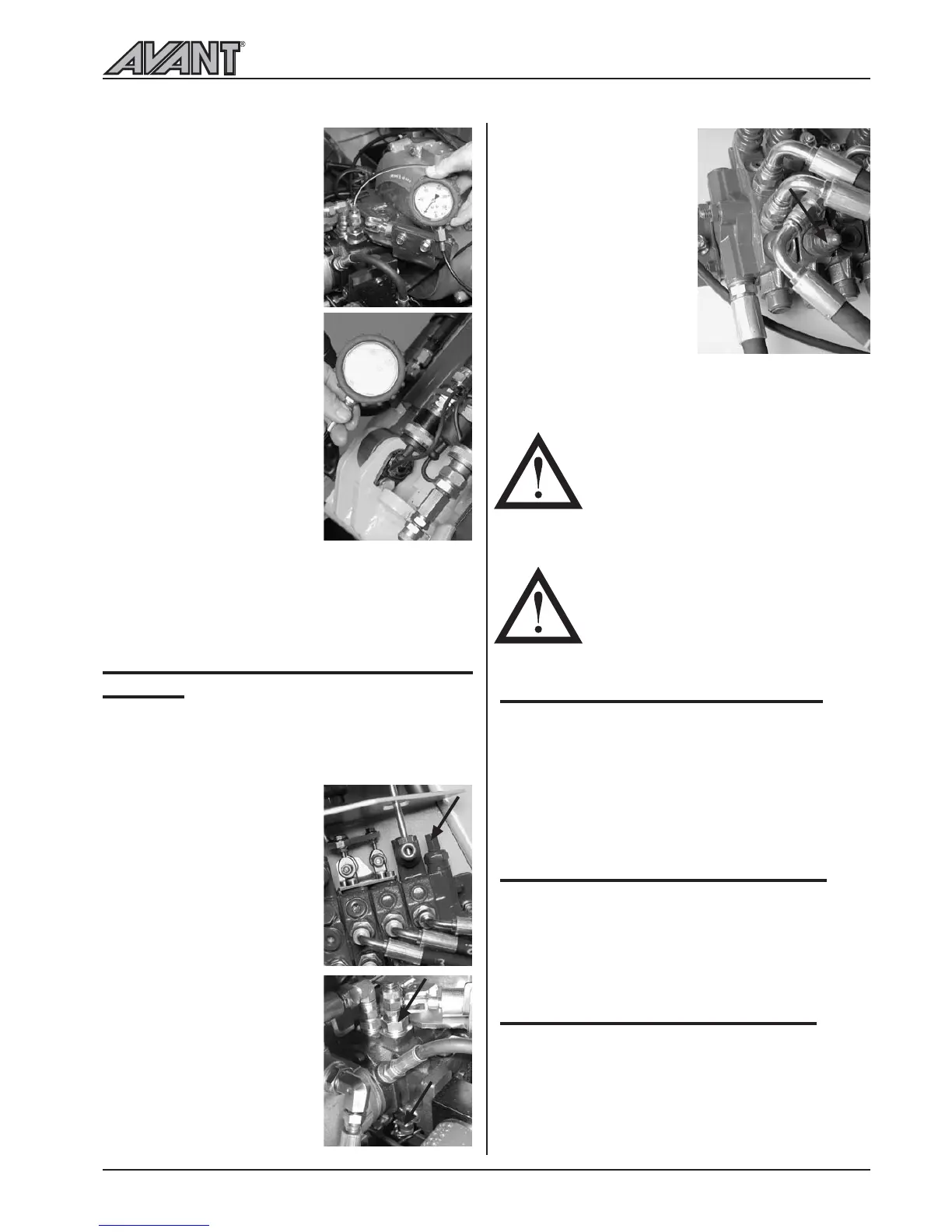

Boom lifting/auxiliary

hydraulics: Pressure is adjusted

from the pressure relief valve

at the main control valve.

Pressure relief valve is the first

section of the control valve, in

front of the first valve block.

Adjust by turning the hexagonal

head screw which is under the

cap.

Drive pressure: Can not be

adjusted. If the pressures are

clearly wrong one must change

the pressure relief cartridges

which have fixed pressure

setting. They are located beside

the pressure checking points.

The cartridge on top of the

pump is for driving forward,

under the pump for reverse

driving.

On models 520+, 523+,

528+ and 530+ the pres-

sure for boom lifting is adjus-

ted from the pressure relief

valve at the main control

valve, in the same way as

mentioned above.

Pressure for auxiliary hydrau-

lics is adjusted from the

shock valve on the valve

segment of aux. hydraulics

pump selection (1-pump ,

2-pump), see picture. The

adjustment screw is under

the cap, adjustment with hexagonal head key.

10. GREASING OF THE MACHINE

Greasing of pivot points is very important in order to

avoid wear. Most of the greasing points are on the

loader boom. There are 15 grease nipples altogether

on a machine with standard boom and 21 grease

nipples on a machine with telescopic boom. The

picture on page 24 shows the location of grease nipples.

11.-18. SERVICE, PETROL ENGINE

AVANT 513 is equipped with the Honda GX390

petrol engine. Service and maintenance instructions

for this engine can be found in the Honda Operators

Manual supplied with the loader.

19.-32. SERVICE, DIESEL ENGINE

Loader models AVANT 514, 520, 520+, 523+,

528+ and 530+ are equipped with a Kubota diesel

engine (see technical specification sheet for the engine

type of each model). Service and maintenance

instructions for the engines can be found in the Kubota

Operators Manual supplied with the loader.

Maintenance instructions

23

500 Series

WARRANTY DOES NOT

COVER DAMAGES CAUSED

BY EXCESSIVE HYDRAULIC

PRESSURE.

NEVER EXCEED THE RECOM-

MENDED HYDRAULIC PRES-

SURE SETTINGS. EXCESSIVE

HYDRAULIC PRESSURE WILL

DAMAGE THE HYDRAULIC

PUMPS, CYLINDERS, AND

HYDRAULIC MOTORS.

Loading...

Loading...