If the average aspirated volume exceeds the permissible

value, the following should be done:

•Remove the pipetting pushbutton, (Fig. 4A),

Warning: The pipetting pushbutton consists of 2 parts:

the lower volume-setting section (Fig. 1A2) and the

upperbutton (Fig. 1A1). After removal of the pushbutton,

both parts will separate.

•Holding the volume setting knob to protect it against

rotation, insert the calibration key into the cuts of the

calibration screw, (Fig. 4B),

•Turn the key clockwise to reduce the aspirated volume,

or counter-clockwise to increase the volume. One full

turn of the calibration key changes the pipette aspiration

volume by the amount given in the table, (Fig. 4C),

•

Take out the key and fix the pipetting pushbutton (Fig. 4D).

The pipetting pushbutton should be fixed by placing the

lower section on the arbor first (Fig. 1A2) and then the

button

(Fig. 1A1).

Determine the average aspirated volume. The average

volume should be within the permissible range shown in

the table. If the volume exceeds the values stated, the

recalibration procedure should be repeated.

When pipetting liquids with physical properties considerably

different from those of water, follow the rules as

described in section 5.

9 - TROUBLESHOOTING

If you notice an improper pipette operation identify the

cause and eliminate the fault. To do this, follow the

instruction in the sequence provided. Replacement of

parts should be required only occasionally, and should

not occur under normal pipette use.

Droplets of liquid remain in the pipette tip.

Possible problem The tip is emptied too fast.

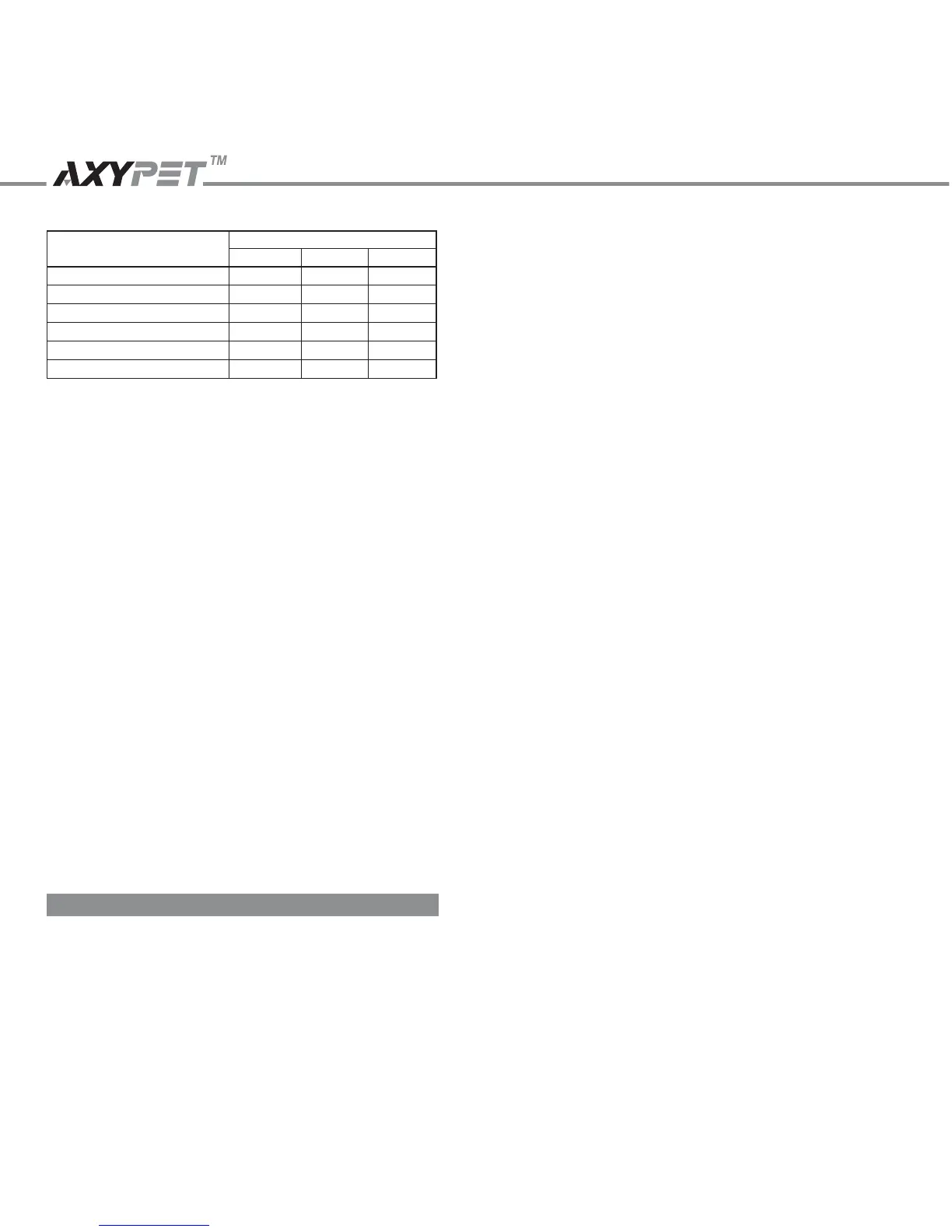

Temperature [°C]

Pressure [kPa]

95.0 101.3 105.0

20

21

22

23

24

25

1.0028

1.0030

1.0032

1.0034

1.0037

1.0039

1.0029

1.0031

1.0033

1.0035

1.0038

1.0040

1.0029

1.0031

1.0033

1.0036

1.0038

1.0040

ENGLISH

11

Action Decrease the speed of pressing the

pipette pushbutton.

Possible problem The tip wettability has increased due

to extensive use.

Action Replace the tip with a new one.

Droplets of air appear in the liquid aspirated into the tip.

Possible problem

The pipette tip immersion is too shallow.

Action Immerse the tip deeper according to

the instructions.

Possible problem The pipette tip is incorrectly pressed

onto the pipette shaft.

Action Press the pipette tip firmly.

Possible problem The tip is damaged or worn out due

to extensive use.

Action Replace the tip with a new one.

The pipette incorrectly aspirates the liquid or liquid

drops out from the tip.

Possible problem The pipette tip is incorrectly pressed

onto the pipette shaft.

Action Press the pipette tip firmly.

Possible problem The shaft nut is loose (Fig. 3F) in the

models AP-2 to AP-1000

Action Tighten the shaft nut.

Possible problem The sealing surface of the shaft is

cracked or scored.

Action Remove the tip ejector. Unscrew the

shaft nut, inspect the shaft and the

piston assembly. Replace the

damaged parts (see Section 12).

When reasembling the pipette, the nut

should be hand tightened.

In the models AP-2, AP-10 and AP-20,

the damage of the shaft may also

cause a damage of the piston assembly.

Replace the damaged parts (see

Section 12).

When reasembling the pipette, the nut

should be hand tightened.

To remove the tip ejector in models

AP-5000 and AP-10ML, remove the

ejector pushbutton (Fig. 3N) and

using a screwdriver unscrew the tip

12

Loading...

Loading...