Fig.1-6

Fig

.

1-7

OP

ER

ATION

Befo

re

use

Pl

ease always read the instruction manual carefully and check the machine before

operating.

WA

RNIN

G

!

Th

e grass trimmer is fitted with a two-stroke engine, so no need fill oil

separately. Fill the

oil

mixed w

ith fuel, please

consul

t

below secti

on.

Make sure the handle and safety features are in good working order. Never use a

machine that lacks a part or has been modified outside its specifications.

The enclosures must be correctly fitted and undamaged before you start the machine.

WA

RNIN

G

!

Please

always use quality gloves, foot, ear and eye protector. They should with CE

mark and tested according to PPE (Person Protective Equipment) directive.

Poor equipments may reduce the protection and result in person injure during working.

Engi

ne

fuel

WA

RNING

!

The grass

trimmer is fitted with a two-stroke engine; use fuel mixed with oil

on

l

y

.

WA

R

NING.

● Do not refill fuel while engine is running or hot.

● Make sure fuel is not leaking.

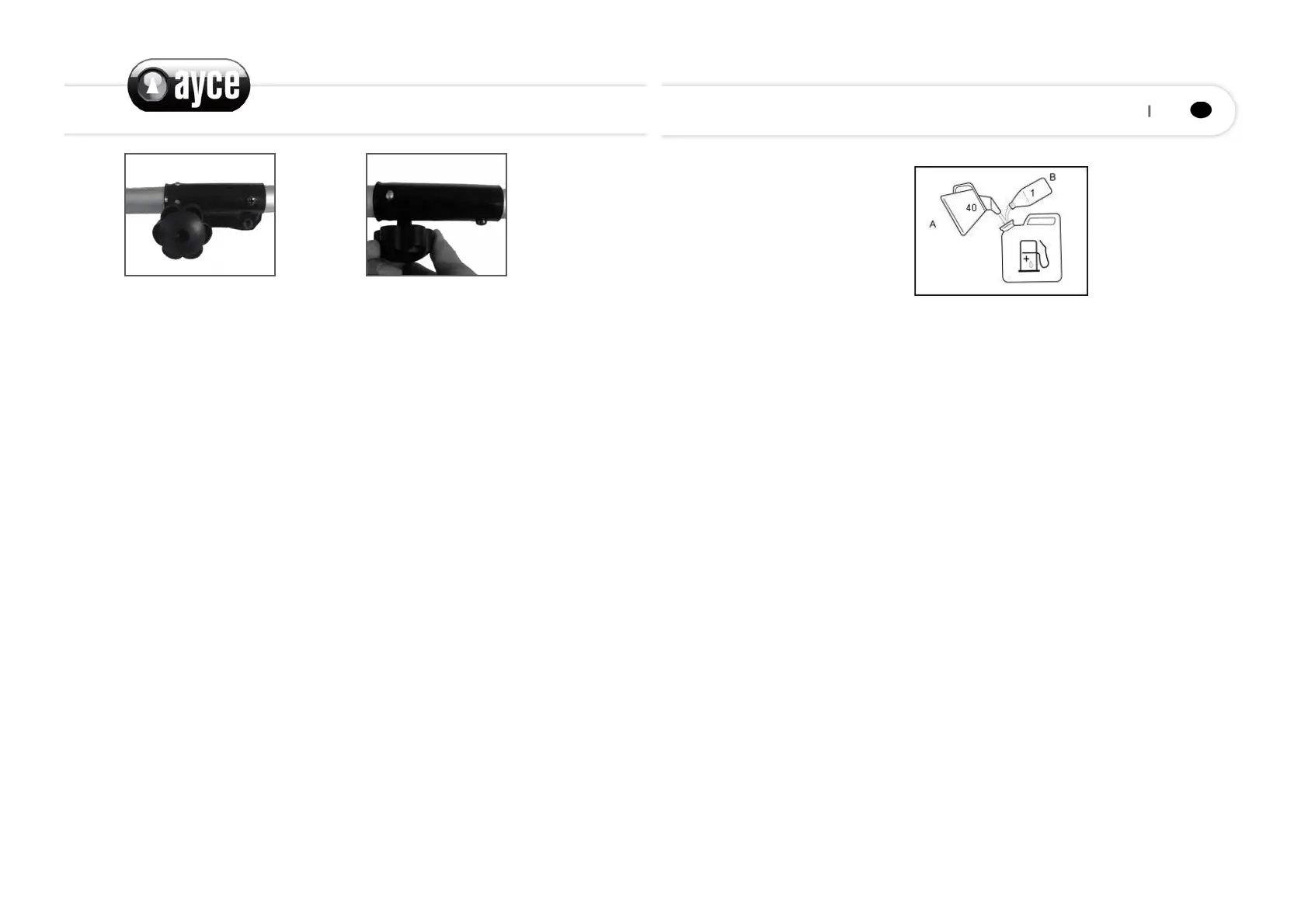

Use quality two-stroke oil and make a mixture of 40 parts petrol(unlead, octan> 90)

to one part oil (special oil for 2 stroke engines)only (2,5% oil

mixe

d

in

fue

l).

N

ever us

e two-stroke oil intended for water-cooled engines. Never use oil intended for

four-stroke engines.

A poor oil quality and/or too high oil/fuel ratio may jeopardize function and decrease

the life time of catalytic converters.

Shake the container well to obtain a correct mixture before filling the tank.

96 97

GB

Us

e at least 90 octane fuel. We recommend unleaded petrol as it leaves fewer

residues inside the motor and on the ignition plug, and prolongs the life cycle of the

exhaust system. Never use old or dirty petrol or oil/petrol mixtures. Avoid

contamination with dirt or water in the tank. Occasionally ignition knocking or clanging

can be heard with high loads. This is normal and no cause for alarm. If ignition

knocking or clanging occurs during normal loads and with constant motor speed you

should change the petrol quality. If this does not solve the problem contact an

authorized specialist dealer.

When working at continuous high revs a higher octane rating is recommended.

Only fuel the machine in well-lit areas. Avoid fuel spillage. Never refuel the machine

during operation. Let the engine cool down for about two minutes before refueling.

Refueling must not be carried out near naked flames, control lamps or spark

producing electrical equipment such as electric tools, welders or sanders.

13. Make sure the machine is turned off, by turn the engine switch to the “off” position.

14. Check the fuel by a visual check , remove the fuel tank cap and reviewing the fuel

level.

15. Because of fuel expands, please fill the tank to the neck of tank only.

16. Turn the fuel tank cap clockwise to assembly it in position.

Starting the

engin

e

WA

RNING

!

The cutting

atta

chment

may s

tart to move when the engine is started. Make sure

the

att

a

chment cannot come into contact with any

ob

j

ect.

Make

sure t

hat no

unauthor

ized

pers

ons are in the working area, otherwise there

is a risk

of

seri

ous personal

inju

ry

.

1.

Turn the engine switch to the” ON “position.

2. Press the intake pump several times until fuel begins to fill the bulb(Fig 1-8)

3. To start a cold engine, move the choke lever to the close position.(Fig.1-9 ),

In order to restart a warm engine, leave the choke lever in the “Open” position.

Loading...

Loading...