Spray-gun cleaner Starter Page 13

equipment and facility engineering

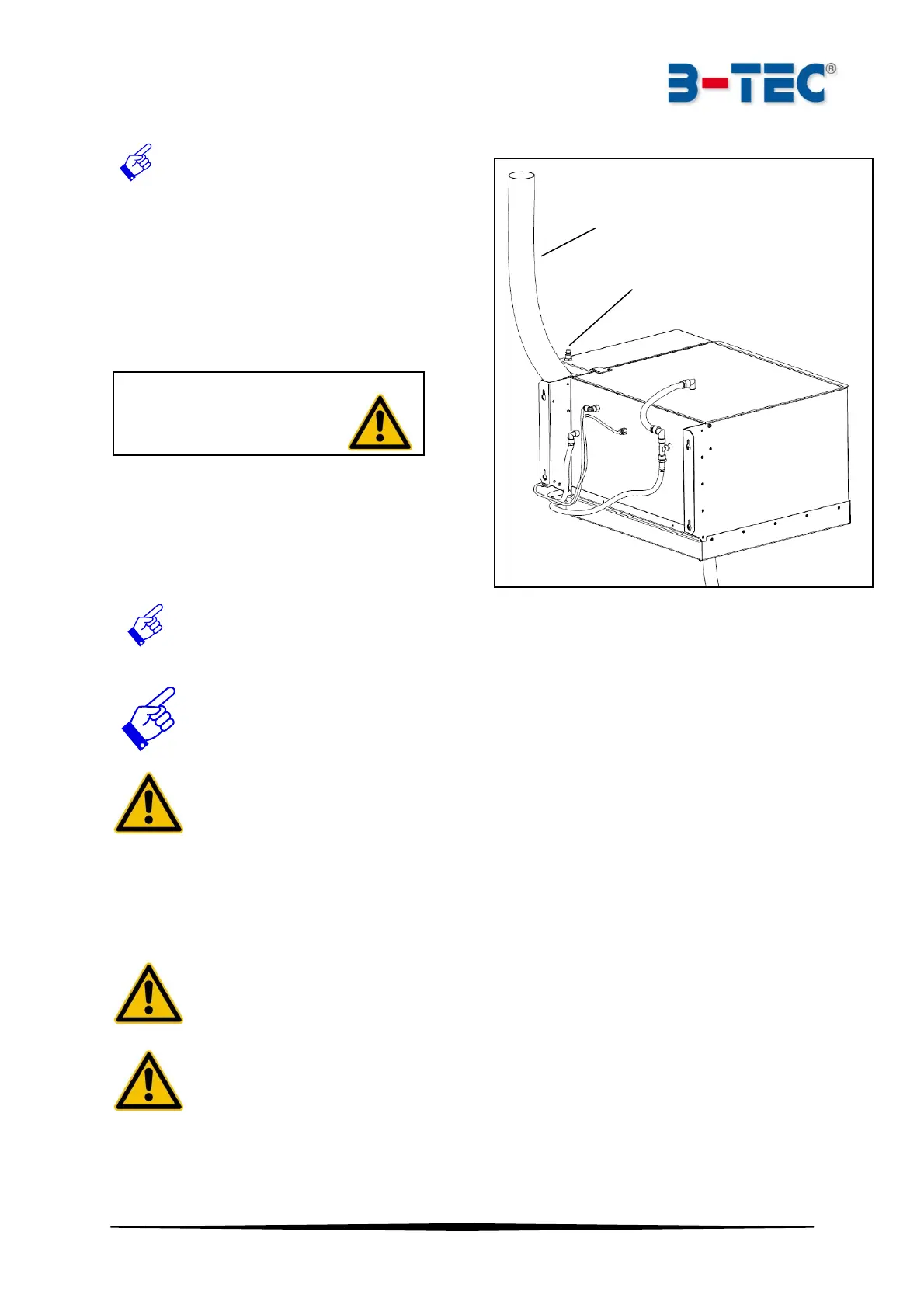

Exhaust

The waste air hose must lead outside. One has to

ensure that the fumes are not led into areas where

people are likely to be. The waste air has to be

exhausted safely. This means that it has not to be

fed into chimneys serving furnaces or fireplaces and

not into exhaust channels of spraying and drying

cabinets

Compressed air connection

One compressed air connection has to be provided

by the plant, depending on the machine:

Operating pressure max : 600 kPa (6 bar ; 87 psi)

Operating pressure min. : 500 kPa (5 bar ; 73 psi)

A pressure-regulating valve has to be used if the compressed air connections do not

have the required operating pressures. Use only dry and oil-free air!!

Grounding: Device has a grounding cable!

In the proximity of the pumps there is a grounding cable, which has to be

grounded safely by a qualified person (e.g. electricians).

Customer-provided solvent tanks must be grounded separately!

After proper installation and connection to the compressed air supply, the cleaning unit can be

commissioned.

Unnecessary dry running of the membrane pumps should be avoided.

Do not open the door when the automatic wash cycle is running.

If necessary, turn the timer to "0".

Attention! Only use original B-TEC

waste air hoses. Risk of fire if

other hoses are used.

Compressed air connection

50.20.05

Loading...

Loading...