www.balluff.com

Construction and function Installation and connection

2english

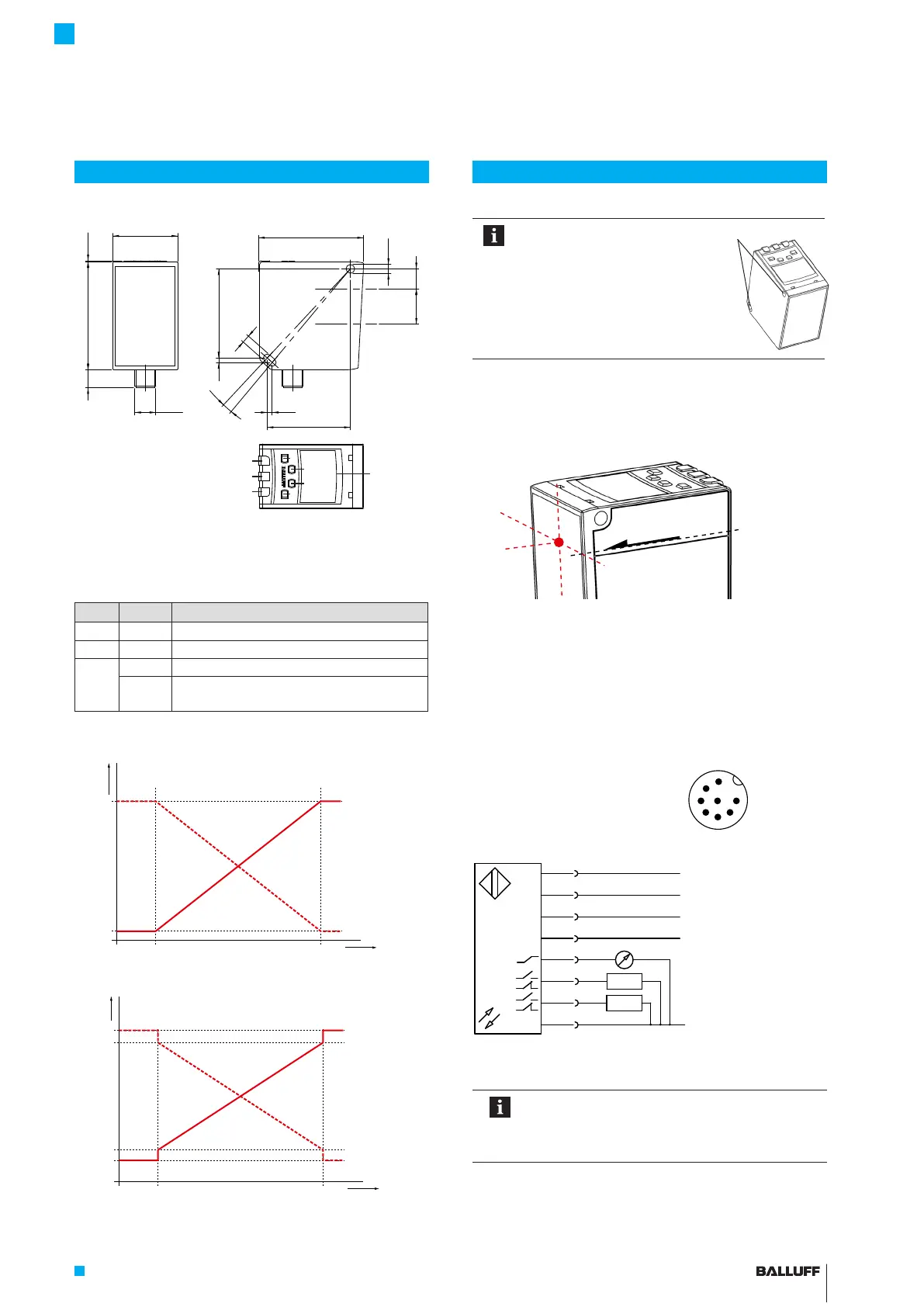

Dimensions

37

10.1

M12x1

61.7 0.5

11.420.2

3.1°

50.82.5

2.9

47.4

60

Ø

5

4,5

6

1

2

3

5

4

7

8

1 ESC button

2 Up button

3 Down button

4 SET button

5 5-digit / Multi Display

6 LED 1

7 LED 2

8 LED 3

LED Color Function

1 Yellow Output Q1 is active

2 Yellow Output Q2 is active

3 Red Measurement is outside the measuring range

Green Sensor is switched on, measurement is

within the measuring range

Output function

MIN

0.2

0

10

V

MAX

mm

Distance

Analog output

MIN

0

20.0

4.0

3.5

20.5

mA

MAX

mm

Analog output

Distance

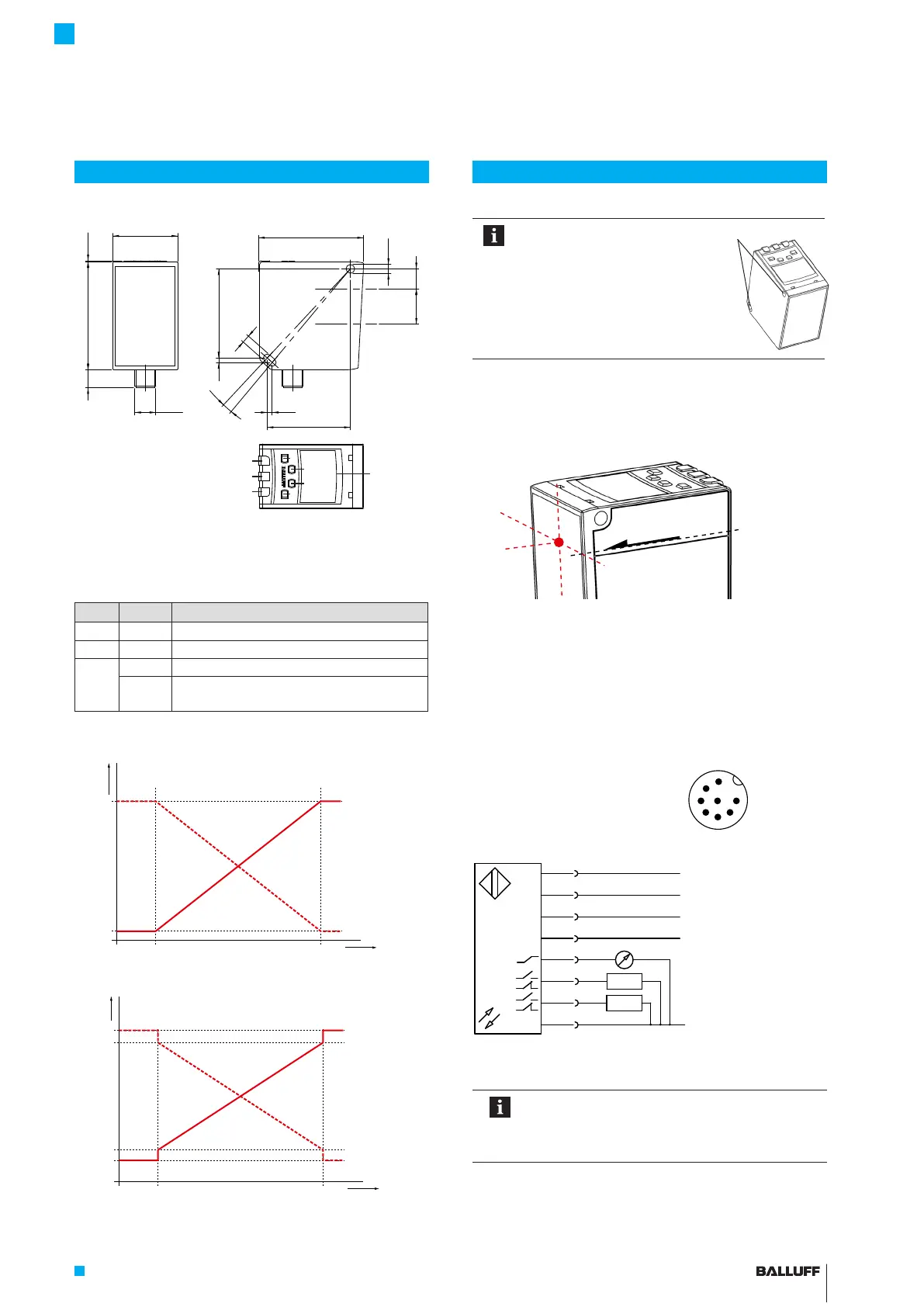

The sensor can be fastened

through two holes in the body (1)

with screws, tightening nuts, and

washers. Only fasten the sensor

to the reference surface marked

with A!

A

1

In case of direct fastening, observe an adjustment angle of

±1.5°. The measurement refers to the front surface of the

laser optics (see figure).

Ref.

1. In a de-energized state, connect the M12 connector to

the sensor.

2. Connect the cable to the supply voltage and I/O as

intended for the respective model.

3. Aim the sensor's laser point at the target and fasten

the sensor in a suitable holder with two screws (e.g.

M4×45, with tightening nuts and washers).

Plug and porting configuration

(Top view of the plug on the BOD)

+24 V ±20 % (U

B

)

RS485 –

RS485 +

Multifunction input (IN)

Analog Out (QA)

Q1 (≤ 100 mA)

Q2 (≤ 100 mA)

0 V

Colors

:Pin:

1)

1

5

4

8

6

3

2

7

WH

GY

YE

RD

PK

GN

BN

BU

1) In conjunction with the plug connector specified under

accessories

The measurement function is available just a few

seconds after the device is switched on. To

achieve full accuracy, a warm-up phase of

approximately 20 minutes must be observed.

8

7

1

2

5

6

4

3

BOD 37M-LPR02-S115

Photoelectric Sensors – Laser Distance Sensor

Loading...

Loading...