2 English

Installation of connections according to DIN 3852

Make sure that:

– The sealing surface on the relevant part is perfectly

clean and free of residues,

– The O-ring seated in the slot provided is undamaged.

1. Screw the device into the mounting thread by hand.

Secure devices to the steel pressure connection using

a flat wrench. Observe the following torque values:

Mechanical installation

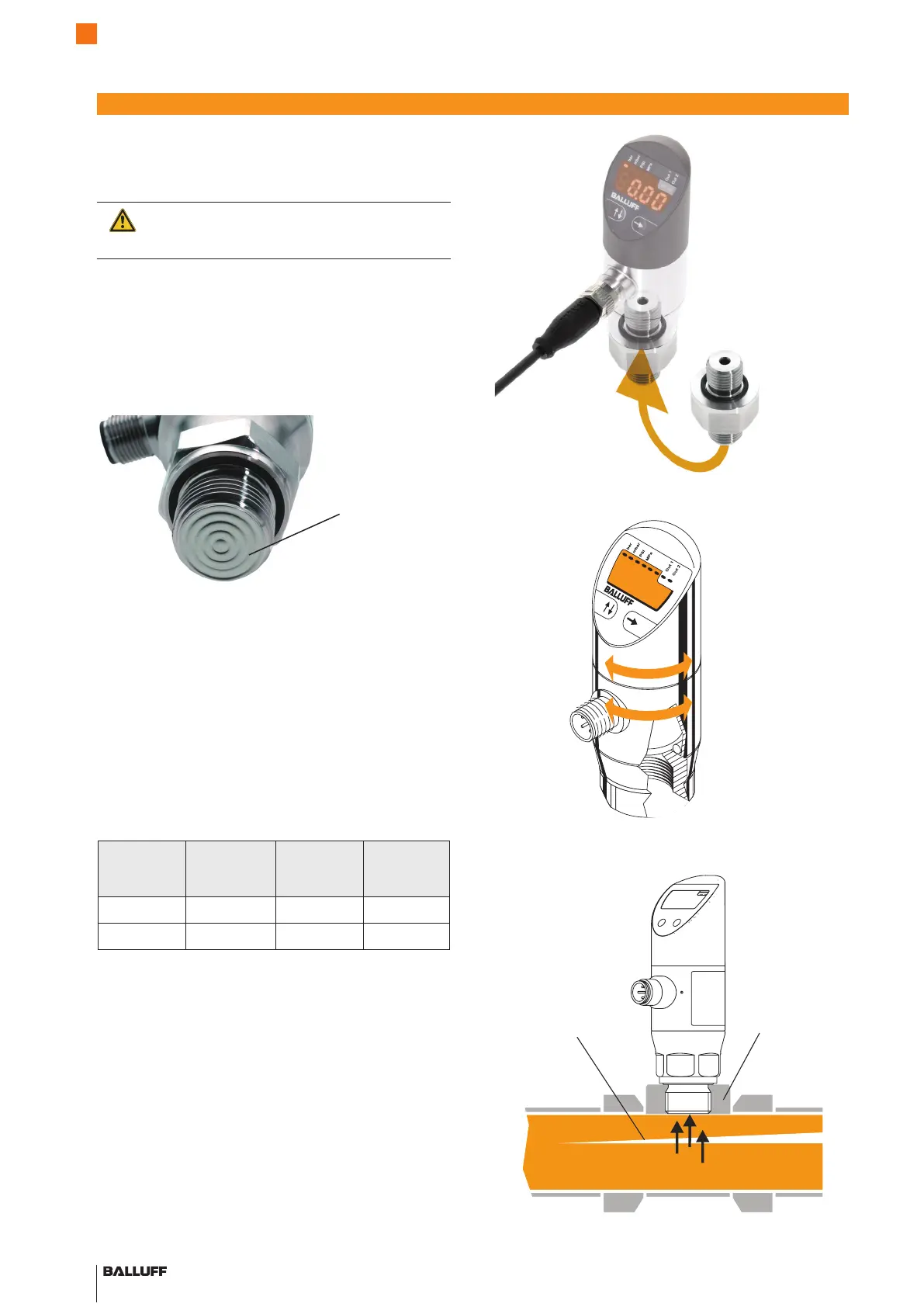

Fig. 2: Electrical connection and process connection

Adapter for process

connection

Torque Connection

per

EN 3852

Connection

per

EN 837

NPT

connection

1/4" approx. 5 Nm approx. 20 Nm

approx. 30 Nm

1/2" approx. 10 Nm approx. 50 Nm approx. 70 Nm

Fig. 3: Display and connection housing rotate 320°

Fig. 4: Process connection for the flush-mounted sensor (G1/2" in

accordance with EN 3852)

Factory-set

connection G1/2"

Fluid

Flush-mounted

sensor

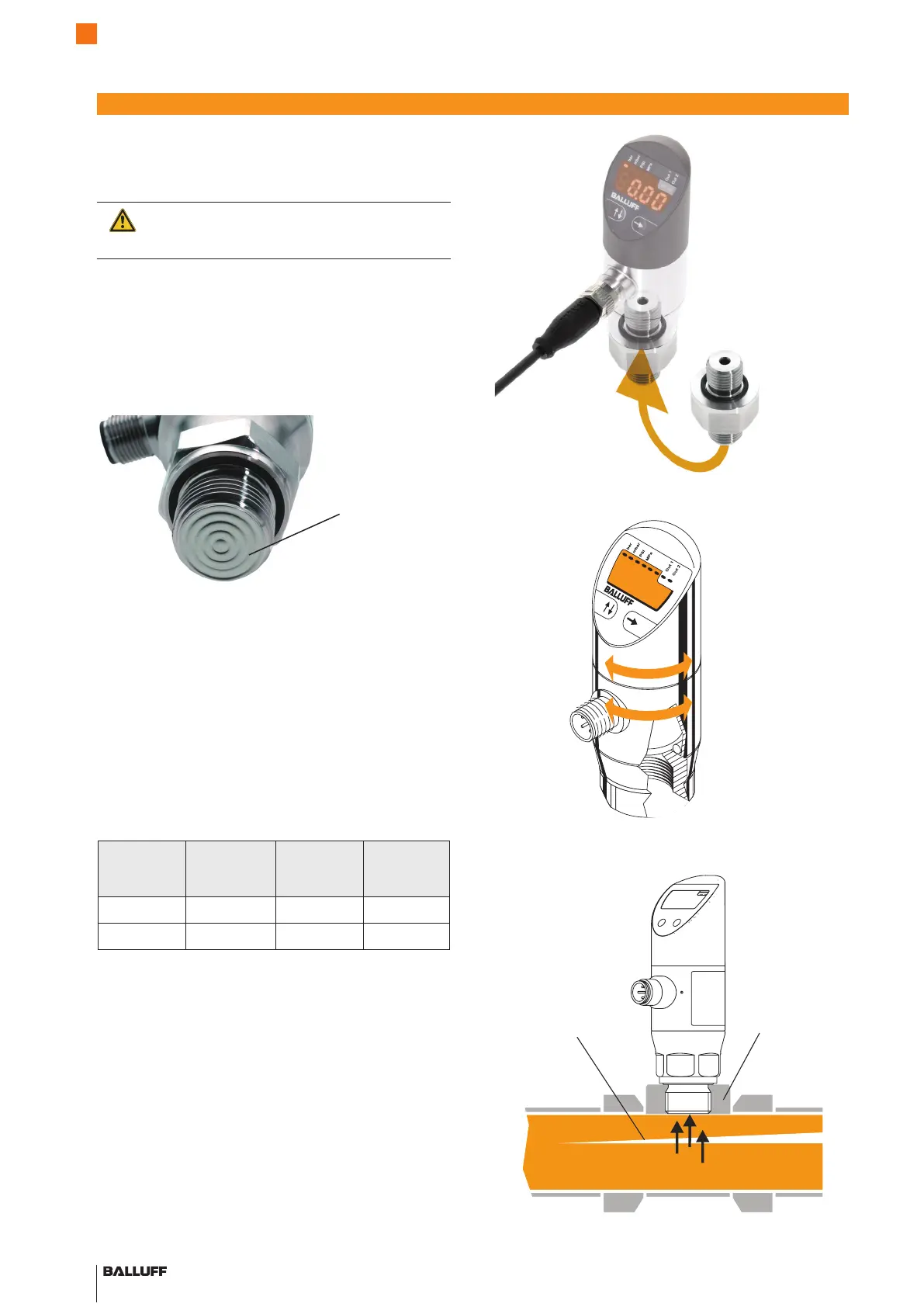

Important notes for installation of flush-mounted

sensors:

Caution!

Handle the unprotected membrane with the

utmost care: it can be easily damaged.

– Do not remove the packaging and protective cap until

shortly before installation, so that the membrane

remains undamaged. Retain the protective cap.

– After disassembly, place the protective cap back over

the membranes immediately.

– Do not use force when installing the sensor, so as not

to cause damage to the device or the system.

Membranes

Fig. 1: Unprotected membrane of the flush-mounted sensor

Pressure Sensors with IO-Link

BSP-B... /-V...

Loading...

Loading...