Operation and Maintenance Manual

495B ML TM (S)

39

Last Updated - 08/31/2016

PUMP ADJUSTMENTS (AA11 SAW PUMP)

ADJUSTING WORKING PRESSURE (2800 PSI) AND STANDBY PRESSURE (425 PSI)

Standby Pressure

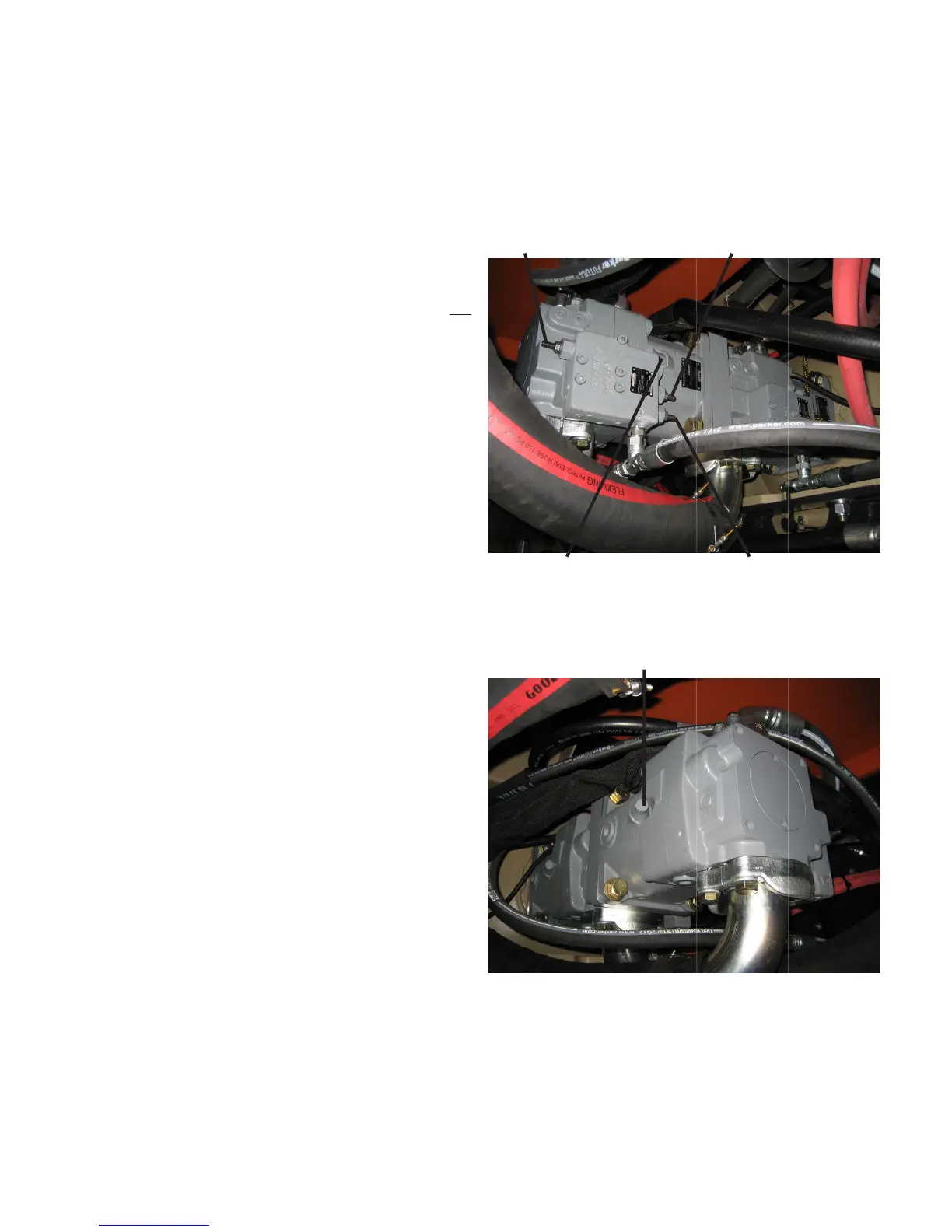

Pump Compensator

Max Displacement (Saw Speed) Adjustment

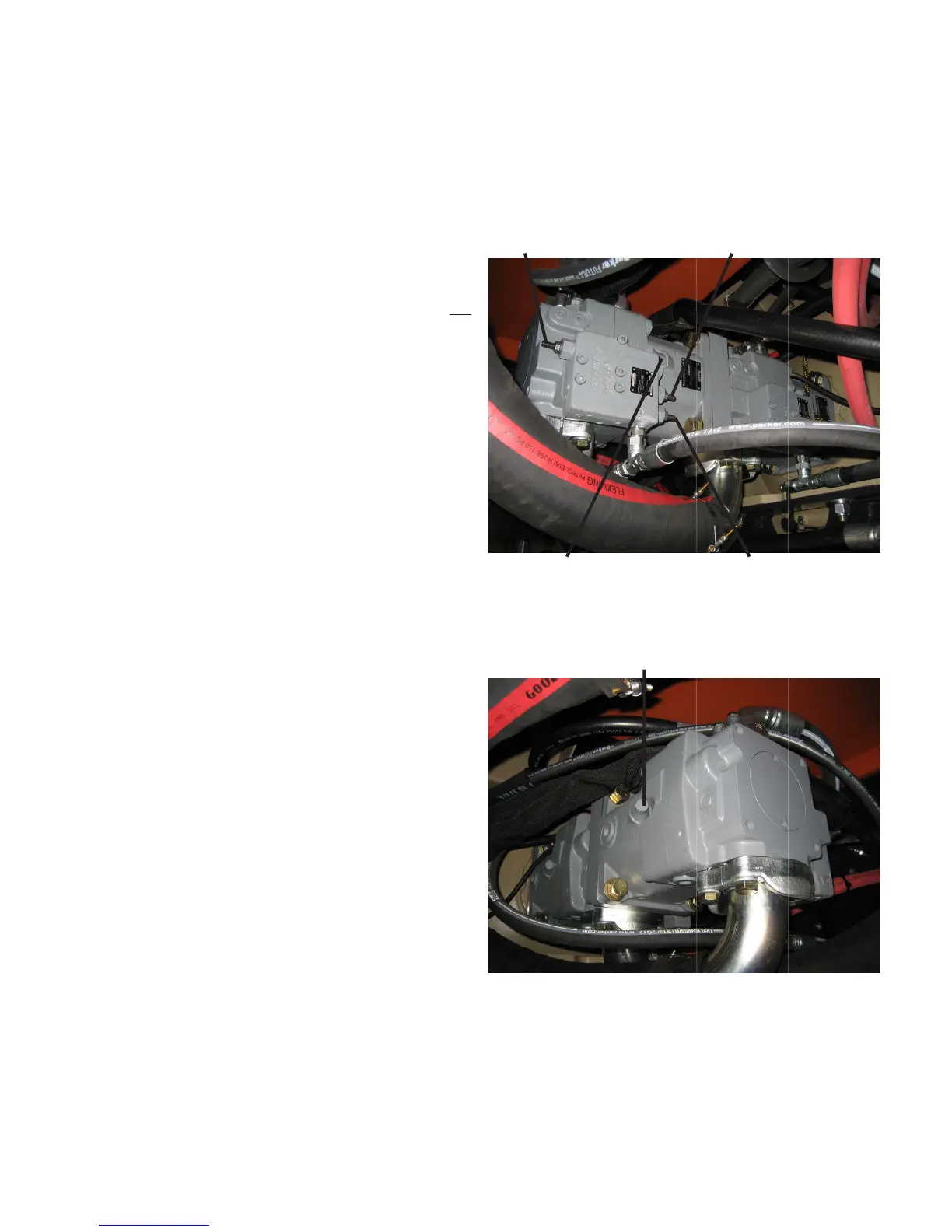

1. Install an electronic (digital) pressure gauge on the

saw pressure test port located next to the pressure

port on the pump.

NOTE: When setting standby pressure, pressure will

spike to approx. 2800 PSI before reading 425 PSI.

This will ruin a 1000 PSI gauge. Use an electronic

(digital) pressure gauge to check standby pressure.

2. Run engine at low throttle with saw OFF.

3. Loosen jam nut on Standby Pressure Adjustment,

with 1/2" wrench.

4. Adjust Standby pressure to 425 PSI by turning

screw in or out with a 5/32" allen wrench.

(turn screw clockwise to increase,

counterclockwise to decrease).

5. Tighten jam nut.

6. Stall saw or plug pressure line.

7. Run engine at full throttle.

8. Turn saw ON.

9. Adjust Pump Compensator Pressure to 2800

PSI by turning screw in or out with a 5/32" allen

wrench. (turn screw clockwise to increase,

counterclockwise to decrease).

10. Tighten jam nut.

11. Turn Saw OFF.

12. Shutdown engine.

13. Unstall saw or replace pressure line.

14. Remove pressure gauge.

The torque control is factory set and generally will not

Minimum Displacement

Adjustment

Torque Control

require adjustment. Turning the screw in (clockwise) will

increase the load on the engine by holding the pumps on stroke at a higher pressure.

SAW SPEED (RPM)

The saw speed can be adjusted using the Max Displacement Adjustment. Turn in to slow saw down and out to

Loading...

Loading...