Operation and Maintenance ManualLast Updated - 08/31/2016

495B ML TM (S)

90

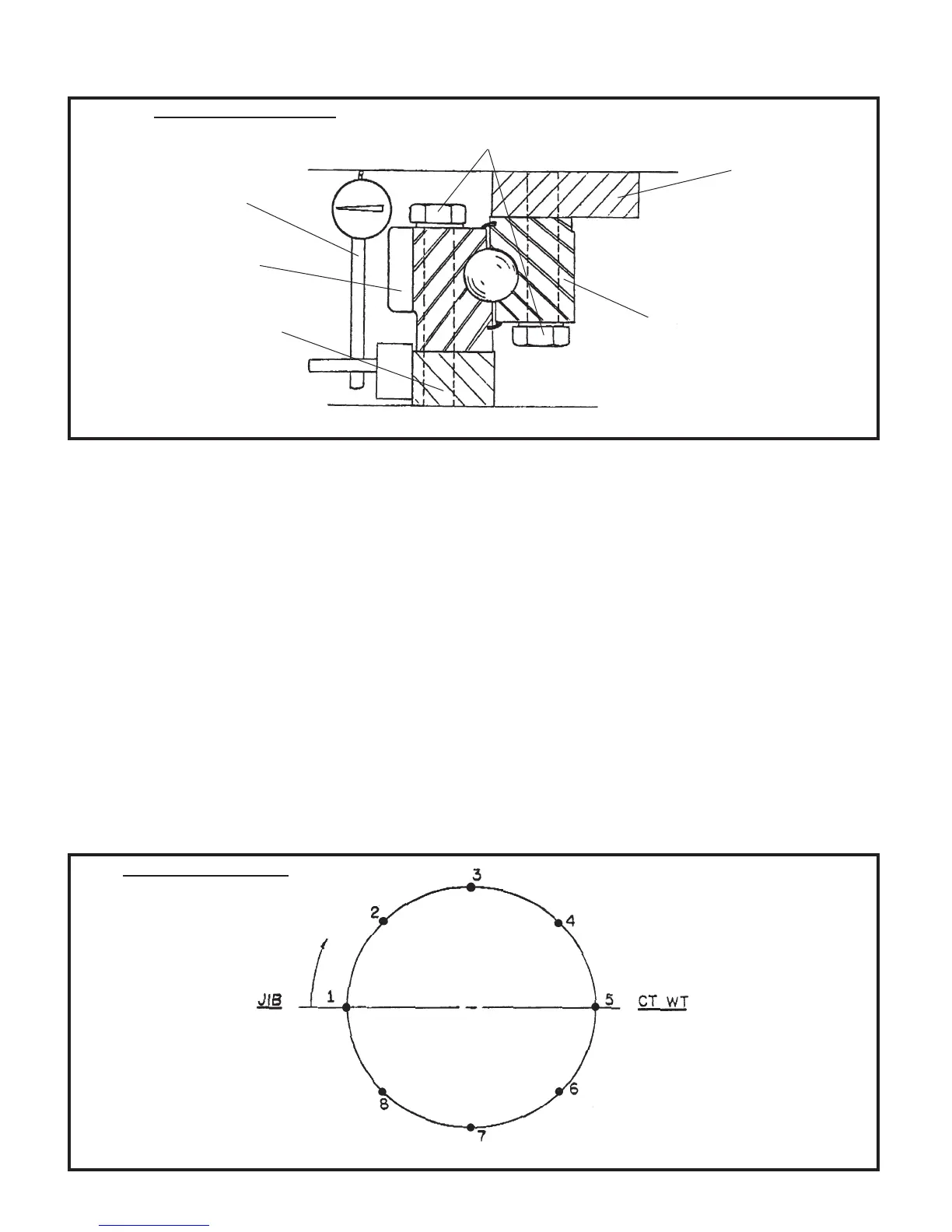

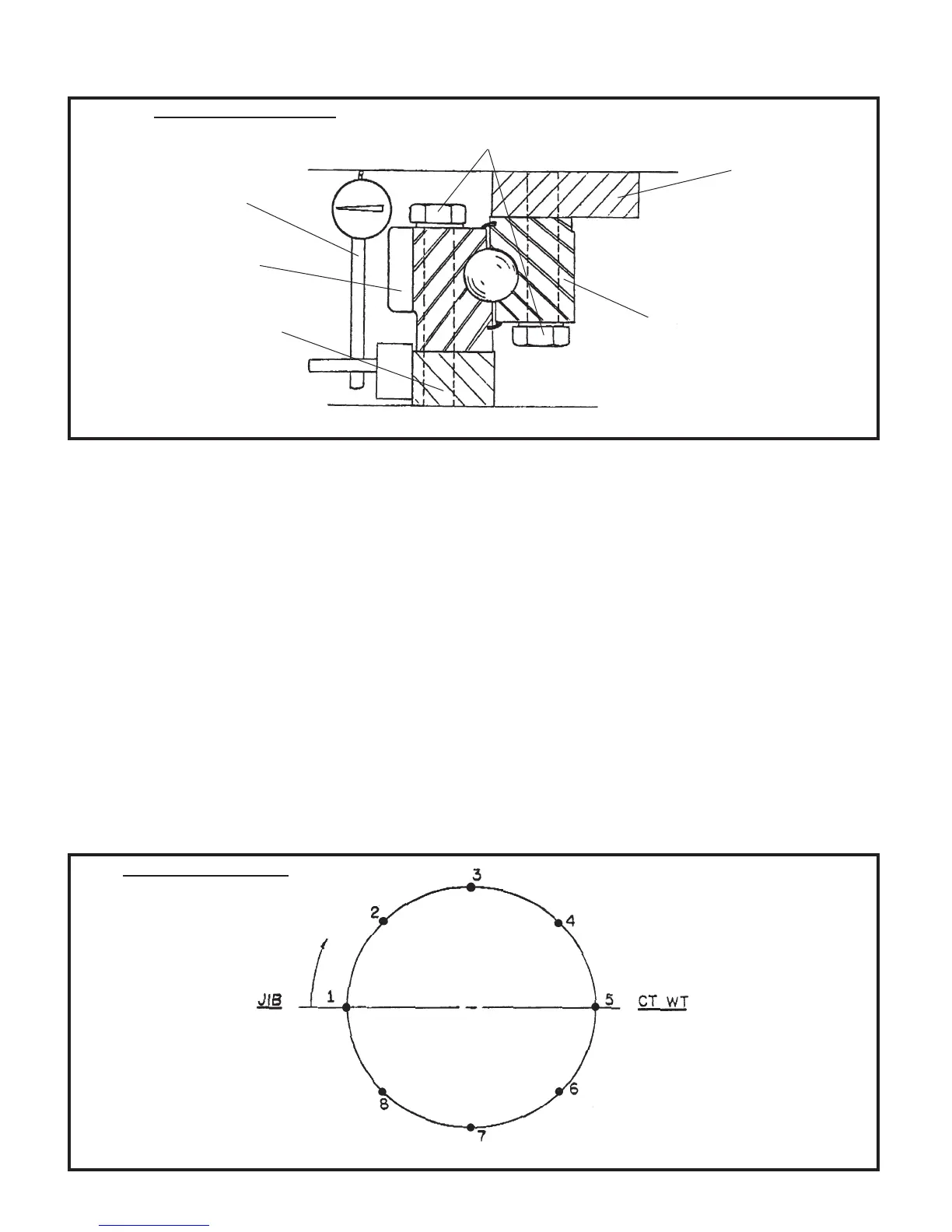

1. Take measurements at 8 equally spaced locations on the bearing. See Figure 2.

2. Rotatemachinesupperworkssothatthecenterlineoftheboomisalignedwiththerstmeasuringlocationand

the centerline of the counterweight is aligned with another measuring location.

3. Place one dial indicator under the centerline of the boom so that a measurement will be taken from the upper

bearing mounting surface or the upper bearing ring to the lower bearing mounting surface or the lower bearing

ring (mark the locations of the dial indicator base and the dial indicator contact point so that the readings can be

repeated). See Figure 1. Set dial indicator.

4. Balance the machine so as to have zero moment load on the bearing. This is done by adjusting the boom angle.

Zero moment is when the upper race is at its lowest position at both front and rear of the upper works - mark

boom angle position so that it may be returned to the same neutral position.

5. Lower the boom to a horizontal position. Do not load the attachment or add extra weight.

6. Read dial indicators and record the measurements.

7. Elevate the boom back to the neutral position (dial indicator should return to zero).

8. Rotate the upper works to the next measurement location and take readings the same as above.

Figure 1

Possible Indicator Position

Dial Indicator

Upper Bearing

Bearing Mounting Bolts

Lower Bearing Mounting

Surface (machine)

Upper Bearing

Mounting Surface

(machine)

TURNTABLE BEARING MAINTENANCE CONTINUED...

Figure 2

Measurement Locations

Lower Bearing

Loading...

Loading...