21-1S00-7D0001/-

05/2023-EHT-466853

Notice Technical data subject to change without notice.

No claims for damage arising from alternations, errors or misprints shall be allowed.

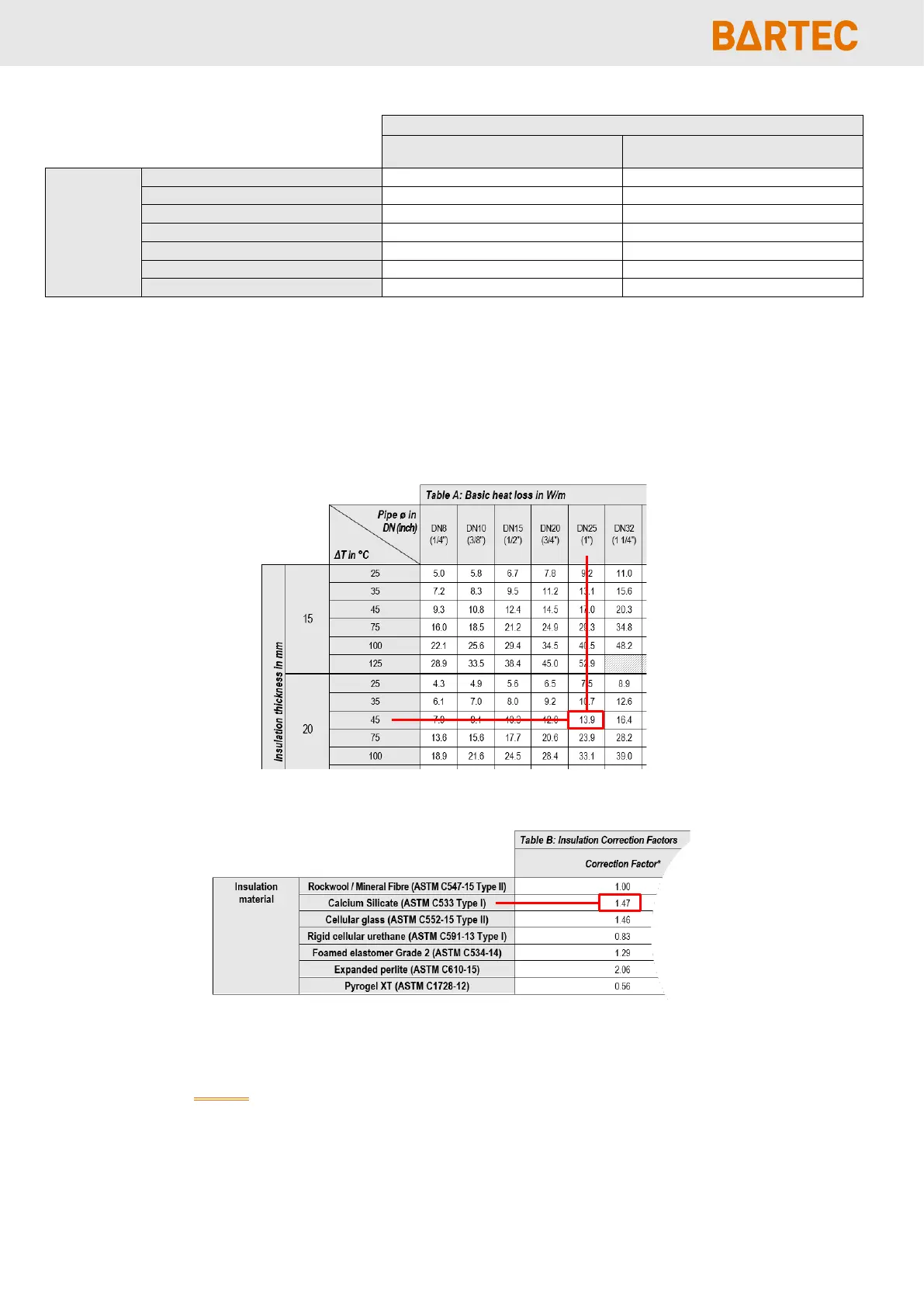

Finally, you must apply the following correction factors depending on your insulation material:

Table B: Insulation Correction Factors

thermal conductivity at 20 °C

in W/m×K

Rockwool / Mineral Fibre (ASTM C547-15 Type II)

Calcium Silicate (ASTM C533 Type I)

Cellular glass (ASTM C552-15 Type II)

Rigid cellular urethane (ASTM C591-13 Type I)

Foamed elastomer Grade 2 (ASTM C534-14)

Expanded perlite (ASTM C610-15)

Pyrogel XT (ASTM C1728-12)

→ Example

Pipe diameter: DN25

Insulation thickness: 20 mm

Insulation material: calcium silicate

Minimum ambient temperature: -20 °C

Maintain temperature: 25 °C

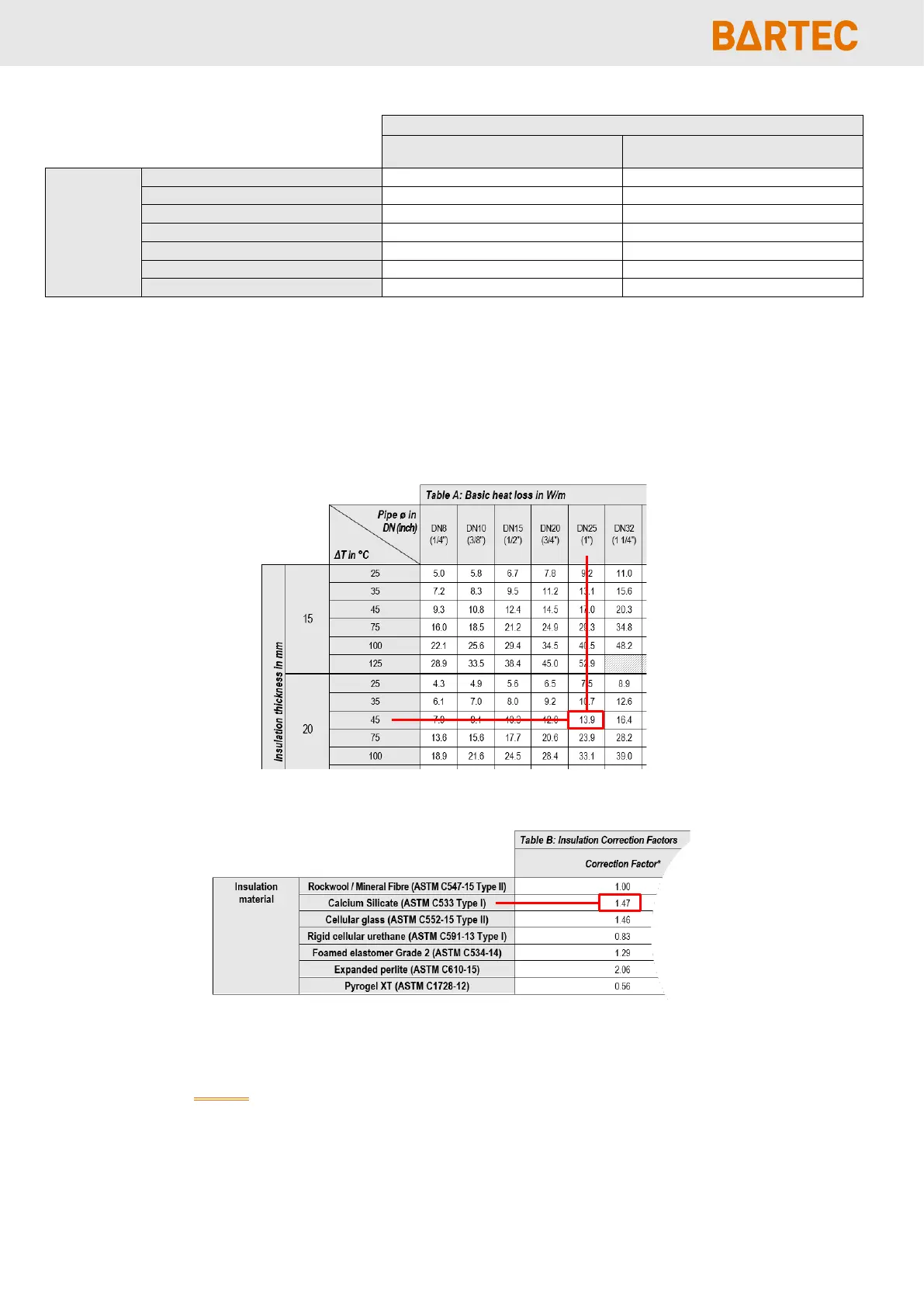

We obtain the basic heat loss in W/m from Table A on page 10:

Now, the correction factors from Table B must be checked and, if necessary, applied:

The effective heat loss of the setup is determined as follows:

effective heat loss = basic heat loss × correction factor insulation

= 13.9 W/m × 1.47

= 20.4 W/m

correction factor insulation: 1.47

ΔT = 25 °C - (-20 °C) = 45 °C

basic heat loss: 13.9 W/m

Loading...

Loading...