4-6 9469200995

Communication DGC-2020ES

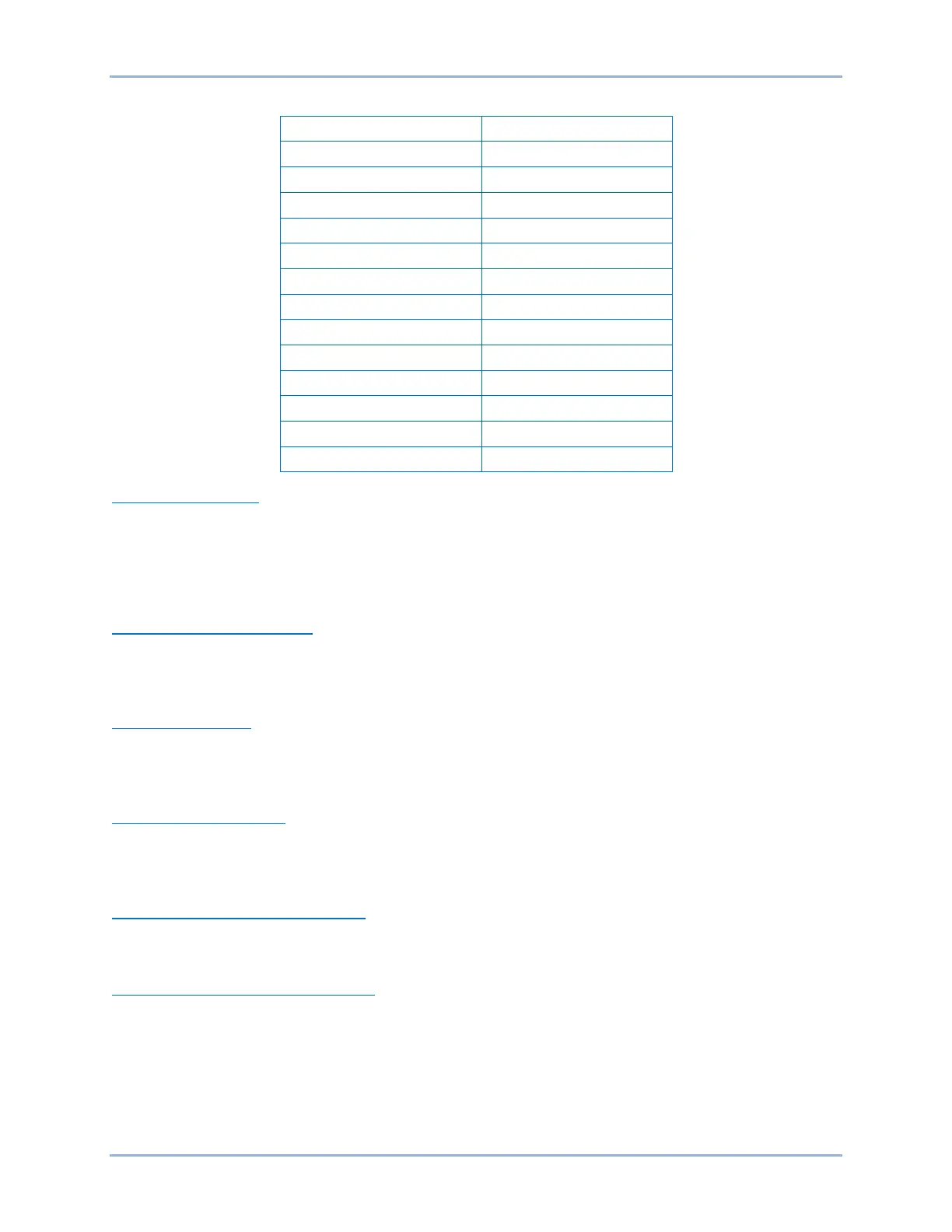

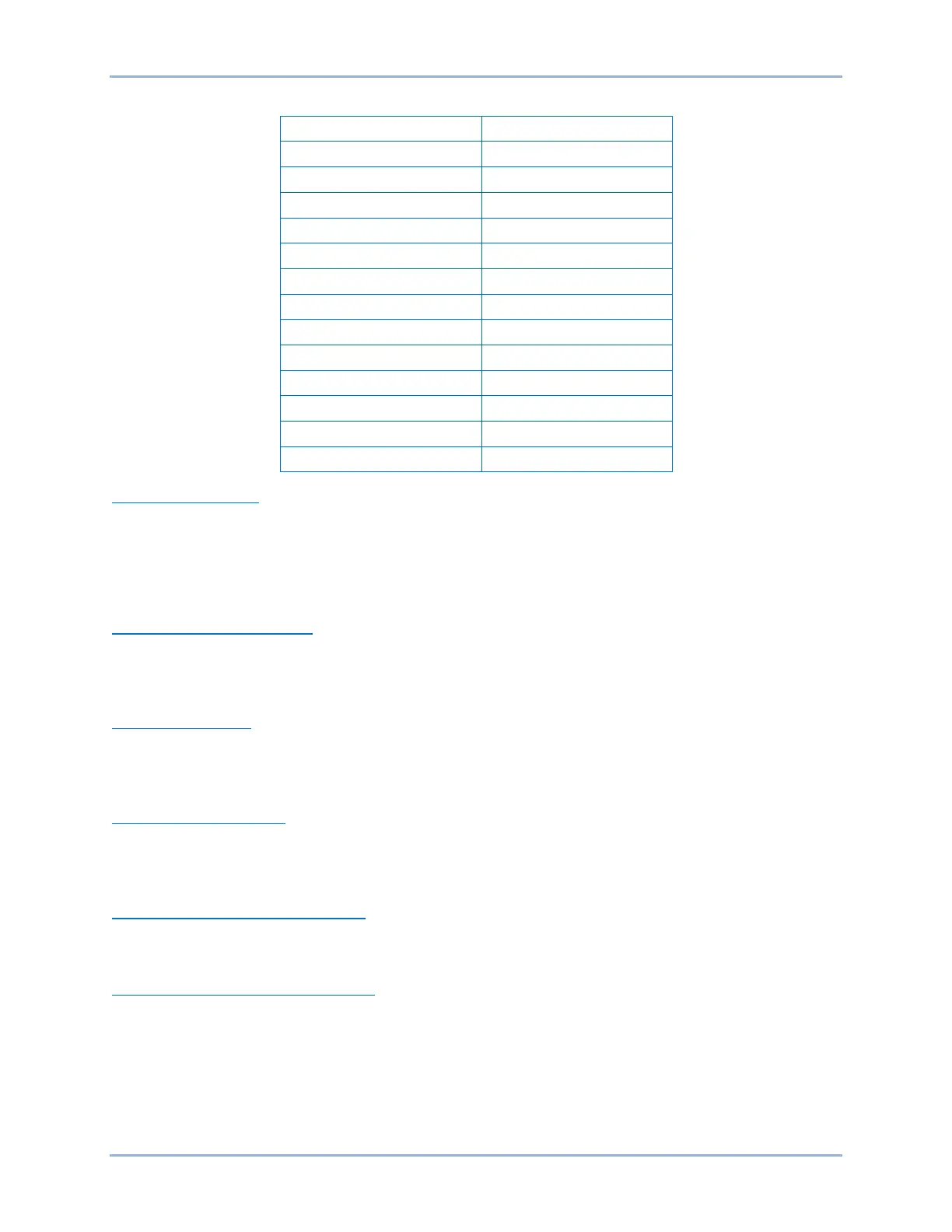

Table 4-4. CAN Bus Address per ECU Type

Engine ECU Address

Set this parameter to the address claimed by the Engine ECU operating on the J1939 network. In certain

cases, there is more than one ECU transmitting data on the J1939 network. This setting specifies the

ECU on the network to which the DGC-2020ES should transmit data. For more information on J1939

address handling, see J1939 Addresses below. When GM/Doosan is selected as the ECU type, the value

of this setting is ignored and the Engine ECU Address value is always 0.

Coolant Temperature Source

With From ECU selected, the DGC-2020ES accepts coolant temperature data from the ECU on CAN 2

(ECU). With From DGC Input selected, the DGC-2020ES accepts coolant temperature data from the

coolant temperature engine sender input.

Oil Pressure Source

With From ECU selected, the DGC-2020ES accepts oil pressure data from the ECU on CAN 2 (ECU).

With From DGC Input selected, the DGC-2020ES accepts oil pressure data from the oil pressure engine

sender input.

Engine Run Time Source

With From ECU selected, the DGC-2020ES accepts Engine Run Time data from the ECU on CAN 2

(ECU). With From DGC Input selected, the DGC-2020ES uses its internally tracked Engine Run Time

data.

ECU Contact Control - Output Select

Select whether the RUN output relay or the PRE (Prestart) output relay closes to give the ECU its

“energize to run” signal. In some implementations, this relay may actually be providing ECU power.

ECU Contact Control - Pulsing Enable

Select if the ECU is not to be on line at all times. Often ECUs are allowed to go “off line” to conserve

battery drain when the engine is not running. The DGC-2020ES will “pulse” it periodically to force it to be

active to allow the DGC-2020ES to read data such as coolant temperature and coolant level. This is

required if the DGC-2020ES is to report low coolant temperature conditions (which may indicate a failure

of a block heater), or low coolant level conditions (if a leak occurs while the machine is not running).

Pulsing is also used to check the integrity of CAN communications when the machine is not running.

Loading...

Loading...