The Bauer 20V HYPERMAX™ LITHIUM 1.6 Gallon Brushless Air Compressor is a portable, cordless air compressor designed for various pneumatic applications. It operates on Bauer 20V Li-Ion batteries (sold separately) and features a brushless motor for efficient performance and extended tool life. This manual provides comprehensive instructions for safe operation, installation, maintenance, and troubleshooting.

Function Description:

The air compressor's primary function is to convert electrical power from a battery pack into kinetic energy in the form of pressurized air. This compressed air is stored in a 1.6-gallon tank and can be used to power a variety of air tools, inflate tires, sports balls, and other inflatables. The brushless motor technology enhances efficiency, reduces wear, and extends the overall lifespan of the compressor compared to traditional brushed motors.

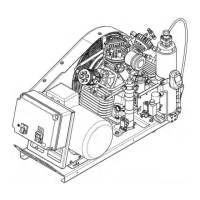

The compressor is equipped with several key components that facilitate its operation:

- Power Switch: Controls the on/off state of the compressor.

- Tank Gauge: Displays the pressure inside the air tank.

- Outlet Gauge: Shows the regulated air pressure being supplied to the air tool.

- Regulator: Allows the user to adjust the output air pressure to match the requirements of the connected air tool or inflatable.

- Safety Valve: An essential safety feature that automatically releases excess pressure from the tank if it exceeds a safe limit, preventing potential bursting.

- Drain Valve: Located at the bottom of the air tank, this valve is used to release accumulated moisture and condensation, which is crucial for preventing internal rust and tank failure.

- Air Outlet: The connection point for air hoses and fittings that lead to air tools or inflators.

- Battery Guide Rails: Securely hold the 20V Li-Ion battery packs during operation.

The compressor's automatic shut-off system is controlled by an internal pressure switch. When the air pressure in the tank reaches 135 PSI, the compressor automatically turns off. It will then automatically restart when the air pressure drops to 105 PSI, maintaining a consistent supply of compressed air without constant manual intervention. This automatic cycling ensures efficient operation and prevents over-pressurization.

Usage Features:

The Bauer Air Compressor is designed for ease of use and versatility, catering to both general household tasks and light-duty industrial applications.

Breaking in the Air Compressor:

Before initial use, a break-in procedure is recommended to ensure optimal performance and longevity. This involves:

- Turning the Power Switch OFF and removing the battery pack.

- Fully opening the Drain Valve.

- Inserting fully charged battery pack(s).

- Turning the Power Switch ON.

- Allowing the unit to run for 30 minutes, expelling air freely through the Drain Valve. This helps seat the internal components and prepares the compressor for regular use.

- Turning the Power Switch OFF, removing the battery pack(s), and closing the Drain Valve after the break-in period.

Air Connection Setup:

The compressor uses 1/4" NPT air outlets. Users need to connect a 1/4" NPT air hose (sold separately) to the Air Outlet. It is recommended to use PTFE tape on the threads of 1/4" industrial fittings (sold separately) to ensure an airtight connection to the air hose. The manual also describes how to connect a 1/4" industrial plug (included) to the coupler for connecting air tools.

General Operation:

- Preparation: Close the Drain Valve and Regulator. Ensure the Power Switch is OFF and insert fully charged battery pack(s).

- Starting: Turn the Power Switch ON. The compressor will automatically build pressure until it cycles off.

- Leak Check: At the beginning of each day's first use, it is important to check for air leaks. This can be done by applying soapy water to connections while the compressor is pumping and after the pressure cut-out. The presence of air bubbles indicates a leak, which should be tightened to prevent the compressor from operating too frequently and increasing wear.

- Pressure Adjustment: The Regulator allows users to set the desired output air pressure. Turning the Regulator clockwise increases pressure, while turning it counter-clockwise decreases pressure. The Air Outlet Gauge displays the set pressure. It is crucial not to exceed the maximum air pressure recommended for the connected air tool or inflatable.

- Emergency Depressurization: If quick depressurization is needed, turn the Power Switch OFF and pull the ring on the Safety Valve to release stored air pressure.

Inflator Use (Tires, Small Inflatables, Sports Balls):

The compressor can be used with various inflator attachments (sold separately or included as accessories).

- Tires and Small Inflatables: Involves threading a tire inflator or appropriate adapter onto the 1/4" Plug, connecting it to the tire valve or inflatable, setting the regulator to the rated pressure, and then removing the inflator once the desired pressure is reached.

- Sports Balls: Requires threading a 1/8" Adaptor onto the 1/4" Plug, then a Ball Needle into the adapter, inserting it into the ball, setting the regulator, and removing the needle when inflated.

- Large Inflatables (Low Pressure): Uses a 1/8" Low Pressure Adaptor and appropriate sized inflator. The regulator should be set to 10 PSI for these applications.

Safety Precautions during Use:

- Always wear ANSI-approved eye protection and heavy-duty work gloves.

- Do not operate the compressor in explosive atmospheres or expose it to rain/wet conditions.

- Keep children and bystanders away from the operating compressor.

- Ensure the work area is clean, well-lit, and well-ventilated.

- Never use the air hose to move the compressor.

- Do not adjust the internal pressure switch, as this can lead to over-pressurization and explosion.

- Do not overinflate items; always check the manufacturer's recommended air pressure.

- The compressor head gets hot during operation; avoid touching it.

- Do not use the compressor to supply breathing air.

Maintenance Features:

Regular maintenance is crucial for ensuring the safe and efficient operation and extending the lifespan of the Bauer Air Compressor. Procedures not explicitly detailed in the manual should be performed by a qualified technician.

Daily Maintenance:

- Drain Moisture from Air Tank: This is the most critical daily maintenance task. The Drain Valve must be opened daily to release all trapped air and moisture from the tank. This prevents internal rust and potential tank failure. To do this, turn the Power Switch OFF, place a collection pan under the Drain Valve, open the valve, tilt the compressor forward to drain, and then close the valve once all pressure and moisture are released.

- Check for Tightness: Ensure all nuts and bolts are tight.

- Noise and Vibration Check: Listen for any abnormal noise or vibration, which could indicate a problem.

- Air Leak Check: Apply soapy water to joints while the compressor is pressurized to identify and tighten any leaking connections.

- Cleaning: Wipe off any oil or dirt from the compressor's external surfaces.

Weekly Maintenance:

- Inspect Air Filter: Check the air filter for accumulated dirt.

Monthly Maintenance:

- Inspect Safety Valve: Ensure the safety valve is functioning correctly.

Air Filter Maintenance:

The air filter needs regular inspection and cleaning to prevent dust and debris from entering the compressor, which can reduce efficiency and cause damage.

- Removal: Remove the cover and filter.

- Cleaning: In a well-ventilated area, away from bystanders, use pressurized air (no more than 15 PSI) to blow dust out of the filter. Wear ANSI-approved safety goggles, a NIOSH-approved dust mask/respirator, and heavy-duty work gloves during this process.

- Replacement: Replace the clean filter and cover.

Battery Pack Maintenance:

- Keep battery packs dry.

- Do not open, drop, short-circuit, puncture, incinerate, or expose battery packs to temperatures greater than 265°F.

- Charge battery packs only according to the charger's instructions.

- Inspect battery packs before every use; do not use or charge if damaged.

- Li-Ion batteries must be recycled or disposed of properly.

- Store battery packs away from metal objects when not in use to prevent short-circuiting.

Troubleshooting:

The manual includes a comprehensive troubleshooting guide to help users diagnose and resolve common issues such as the compressor not starting, building pressure too slowly, not building enough air pressure, overheating, excessive starting/stopping, excessive noise, moisture in discharge air, safety valve "pops," and air leaks. Solutions range from checking battery connections and air filters to tightening fittings and draining moisture. For more complex issues, it advises seeking service from a qualified technician.

The Bauer 20V HYPERMAX™ LITHIUM 1.6 Gallon Brushless Air Compressor is a robust and user-friendly tool, designed for reliable performance when proper operating and maintenance procedures are followed.

Loading...

Loading...