– 4 –

OPERATION

The following pages cover the operation procedures for the various control options of the Proofer

and Retarder/Proofer cabinets. The control panels come in two congurations: standard proofer and

retarder/proofer.

PROOFING

Controlled temperature and humidity in the proofer promotes yeast fermentation, which generates gas and

causes the dough to rise. Proong takes from 45 to 60 minutes, depending on the product. A temperature

setting of 95°F (35°C) and humidity at 85% are typical but will vary slightly, depending on the product

being proofed. To dry-proof, set the humidity to the lowest setting. The chart below is only a guide. Ask

your dough supplier for technical product reports to set up your own chart.

RETARDING

The retard feature gradually thaws frozen dough. Set the temperature between 36°F and 38°F (2°C

to 3°C) for best results. Thawing frozen dough at retarder temperatures takes approximately 6 hours

minimum. Retarding slows the yeast fermentation process, reduces gas formation and inhibits the dough

from rising. This also provides an excellent environment for storing dough products up to 48 hours by

keeping the dough interior cool. Dough should not be refrozen after thawing.

It is likely that condensation will form if product is placed directly into the proofer from the retarder. For

best results, allow the product to reach room temperature before placing into the proofer.

Units equipped with auto mode will slowly and automatically bring the proofer up to temperature without

removing the product from the unit.

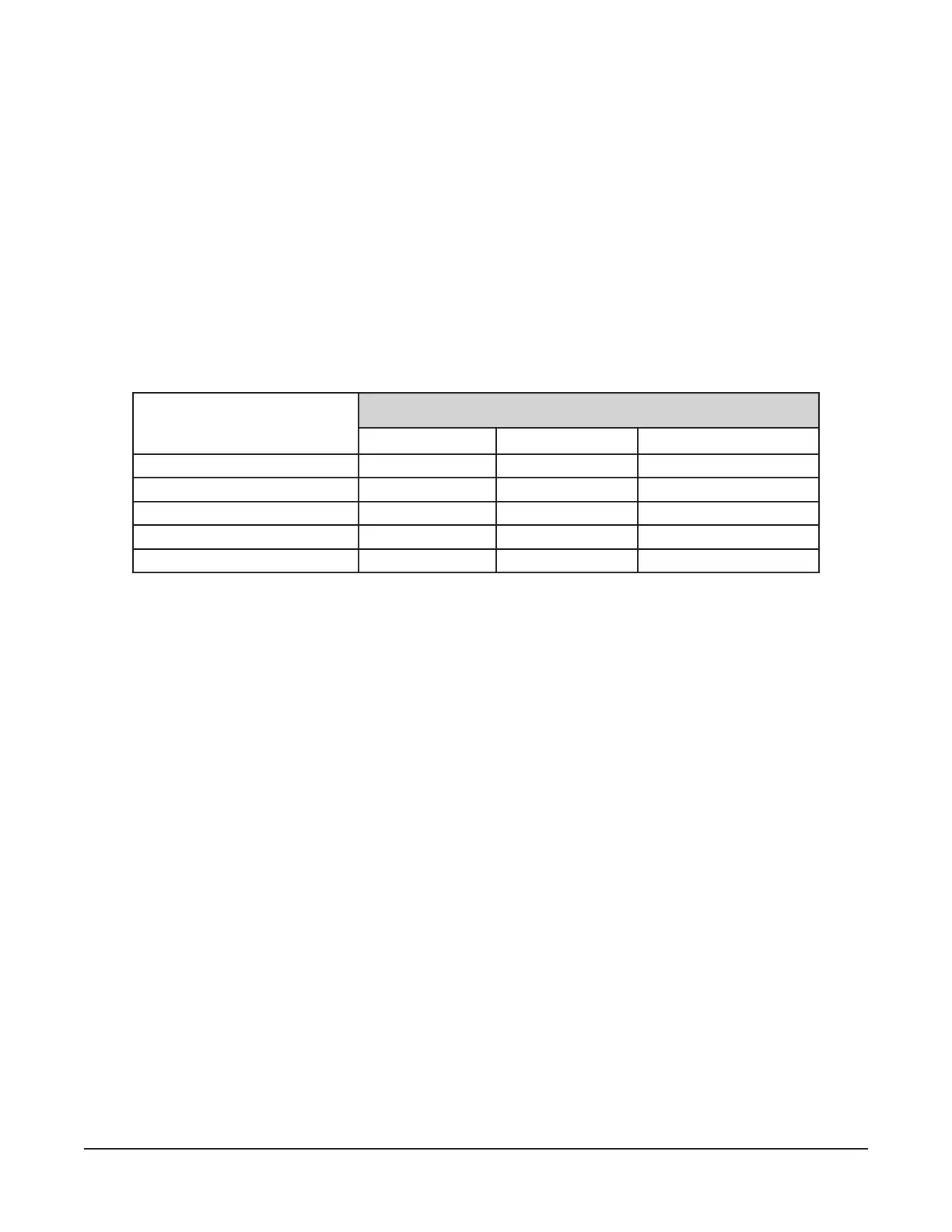

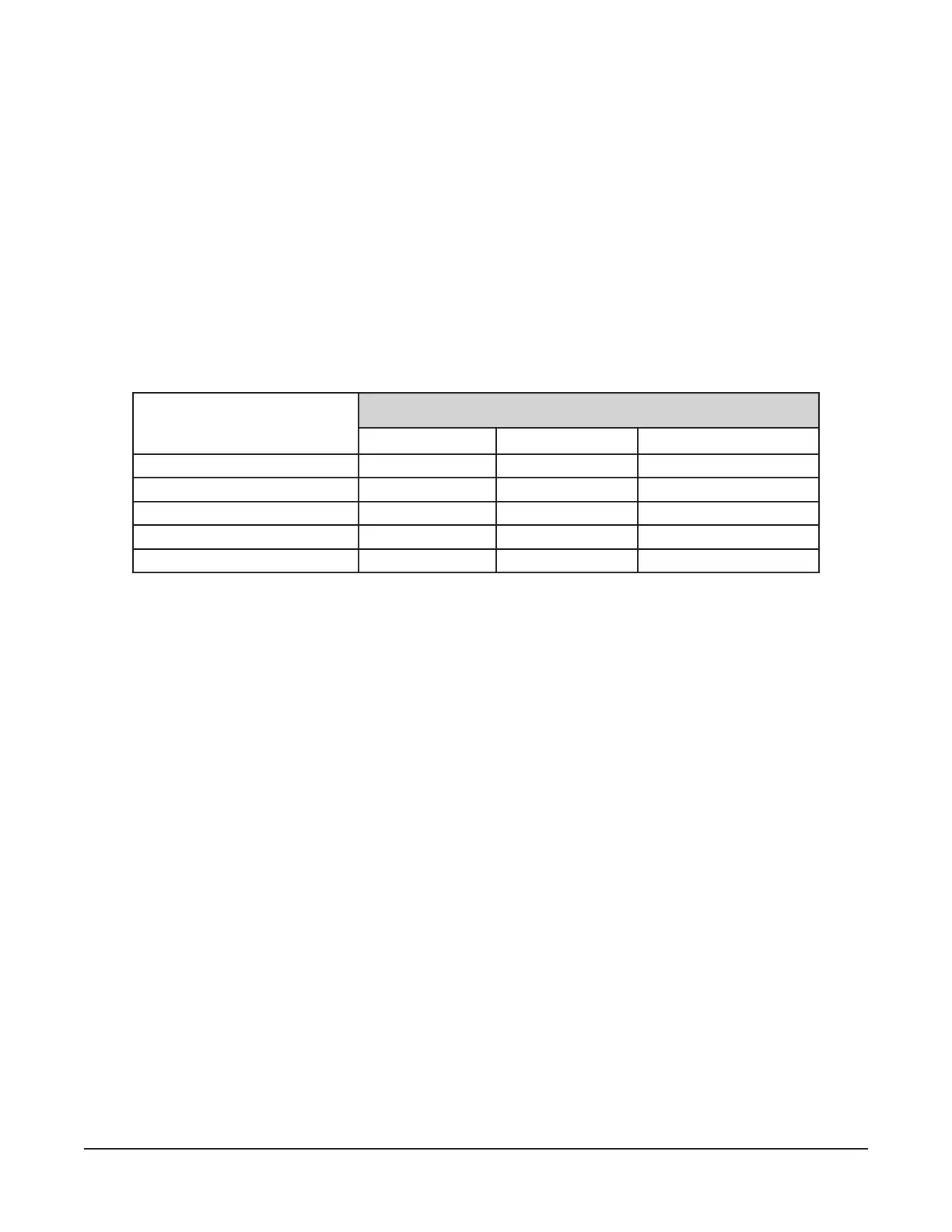

Product

Proong

Temperature % Humidity Proof Time Minutes

Rolls 95°F (35°C) 85% 55 min.

French Crust Bread 14 oz. 90°F (32°C) 90% 45 min.

French Crust Bread 10 oz. 90°F (32°C) 85% 45 min.

Bagels 85°F (29°C) 85% 50 min.

Croissants 75°F (24°C) 70% 30 min.

Loading...

Loading...